Method for grafting humic acid into high water absorption resin and high water absorption resin obtained by same

A technology of humic acid and humate, applied in the direction of chemical instruments and methods, applications, organic fertilizers, etc., can solve the problem of low humic acid grafting amount, and achieve the effect of high water absorption and high salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

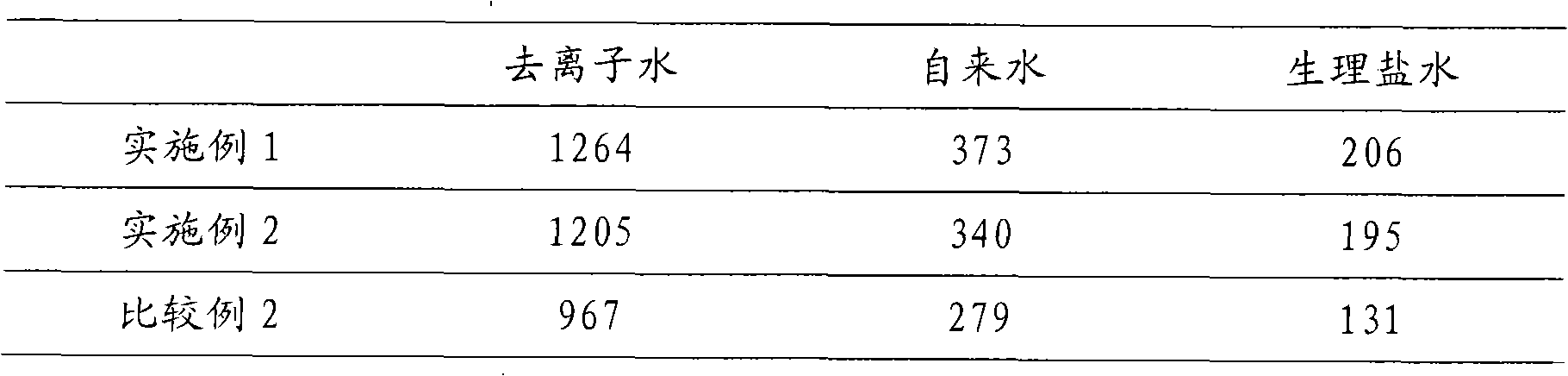

Embodiment 1

[0029] Add 15 parts by weight of acrylic acid into the beaker, and then add a certain amount of NaOH solution, so that the neutralization degree of acrylic acid and acrylate reaches 85%. After the reaction is completed, add 9 parts by weight of acrylamide solution, add 42 parts by weight of water, and stir to dissolve After uniformity, add 0.04% of the weight of the acrylic acid crosslinker N, N'-methylenebisacrylamide and 0.05% of the initiator K 2 S 2 o 8 , stirred at 80°C for 45 minutes, cooled to 25°C, added 7.2 parts by weight of NaClO and 7.8 parts by weight of NaOH (the ratio of the amount of substances was about 1:2), stirred at this temperature for 1 hour, and then heated to 70 Continue to polymerize at about ℃, control the degree of polymerization, so that 4.5 parts by weight of sodium humate can be mixed evenly by stirring smoothly. After adding sodium humate, continue to polymerize at a temperature of 70° C. until a jelly-like polymer is obtained. After the poly...

Embodiment 2

[0031] Add 15 parts by weight of acrylic acid into the beaker, and then add a certain amount of NaOH solution, so that the neutralization degree of acrylic acid and acrylate reaches 85%. After the reaction is completed, add 9 parts by weight of acrylamide solution, add 42 parts by weight of water, and stir to dissolve After uniformity, add 0.04% crosslinking agent N, N'-methylenebisacrylamide and 0.05% initiator K relative to the amount of acrylic acid 2 S 2 o 8 , stir well. Stir at 60°C for 2 hours, cool down to 25°C, add 9 parts by weight of NaClO and 9.7 parts by weight of NaOH (the ratio of the amount of substances is 1:2), stir for 1 hour, heat up to about 80°C to continue polymerization, and control polymerization To such an extent that 4.5 parts by weight of sodium humate can be smoothly mixed by stirring. After adding sodium humate, continue to polymerize at a temperature of 70° C. until a jelly-like polymer is obtained. After the polymer is cooled, take it out, cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com