Method for biochemically treating coking wastewater

A technology for coking wastewater and biochemical treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor ammonia nitrogen treatment effect, large amount of sludge and complex process of coking wastewater and other problems, to achieve the effect of reducing the dosage of alkalinity, occupying less land, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

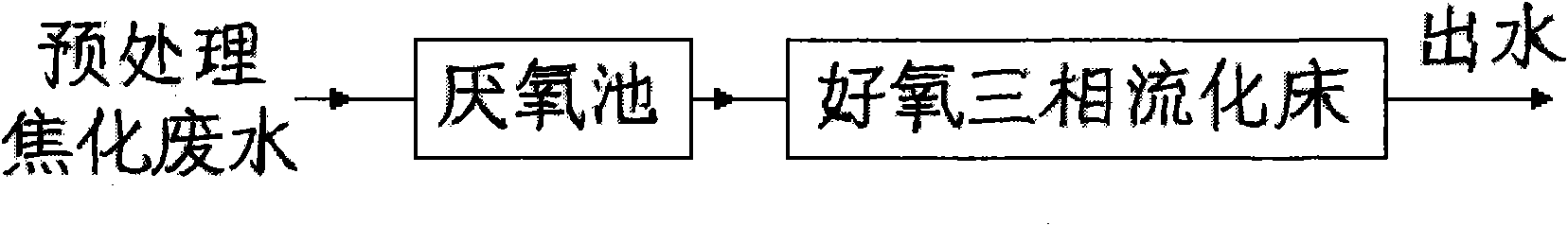

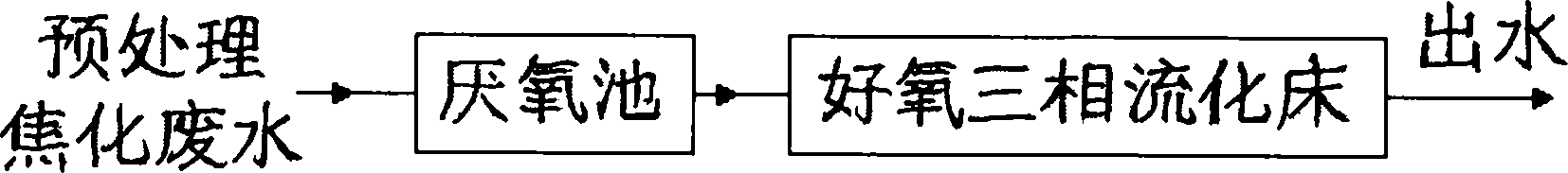

[0025] A kind of coking wastewater biochemical treatment method of the present invention comprises the following steps: (1) coking wastewater is pretreated, and the pretreatment process can be a micro-electrolysis process; (2) coking wastewater after pretreatment enters an anaerobic tank for Anaerobic treatment, influent COD, ammonia nitrogen, volatile phenol and cyanide are about 2600mg / L, 120mg / L, 160mg / L and 32mg / L respectively; the anaerobic tank is a mechanically stirred upflow anaerobic sludge bed ( UASB), the pH of the anaerobic pool is 6.8-7.2, and the hydraulic retention time is 24h; (3) The wastewater after anaerobic treatment enters the aerobic three-phase fluidized bed for aerobic treatment; the aerobic three-phase fluidized bed is Internal circulation three-phase fluidized bed, in which light carrier is added to cultivate a large number of microorganisms in the form of fluidized biofilm. The pH of the aerobic three-phase fluidized bed is 7.8, the hydraulic retentio...

Embodiment 2

[0027] A kind of coking wastewater biochemical treatment method of the present invention comprises the following steps: (1) coking wastewater is pretreated, and the pretreatment process can be a micro-electrolysis process; (2) coking wastewater after pretreatment enters an anaerobic tank for Anaerobic treatment, influent COD, ammonia nitrogen, volatile phenol and cyanide are about 3500mg / L, 55mg / L, 950mg / L and 36mg / L respectively; the anaerobic tank is a mechanically stirred upflow anaerobic sludge bed ( UASB), the pH of the anaerobic tank is 6.5, and the hydraulic retention time is 30h; (3) The wastewater after anaerobic treatment enters the aerobic three-phase fluidized bed for aerobic treatment, and the aerobic three-phase fluidized bed is the internal circulation Type three-phase fluidized bed, in which immobilized microorganisms are directly added, the pH of the three-phase fluidized bed is 8.2, the hydraulic retention time is 20h, the dissolved oxygen is 3mg / L, and the ef...

Embodiment 3

[0029] A biochemical treatment method of coking wastewater of the present invention comprises the following steps: (1) pretreatment of coking wastewater, the pretreatment process may be a flocculation process; (2) pretreated coking wastewater enters an anaerobic tank Oxygen treatment, influent COD, ammonia nitrogen, volatile phenol and cyanide are about 3100mg / L, 65mg / L, 910mg / L and 31mg / L respectively; the anaerobic tank is a mechanically stirred upflow anaerobic sludge bed (UASB ), the pH of the anaerobic pool is 6.0, and the hydraulic retention time is 8h; (3) The wastewater after anaerobic treatment enters the aerobic three-phase fluidized bed for aerobic treatment, and the aerobic three-phase fluidized bed is an internal circulation type Three-phase fluidized bed, in which immobilized microorganisms are directly added, the pH of the three-phase fluidized bed is 7.5, the hydraulic retention time is 8h, the dissolved oxygen is 2mg / L, and the effluent COD, ammonia nitrogen, v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com