Aluminum brazing furnace

An aluminum brazing and brazing technology, applied in welding equipment, electric heating devices, metal processing equipment, etc., can solve the problems of small cooling area, uneven wind speed, and high labor intensity, so as to reduce the use cost, improve work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

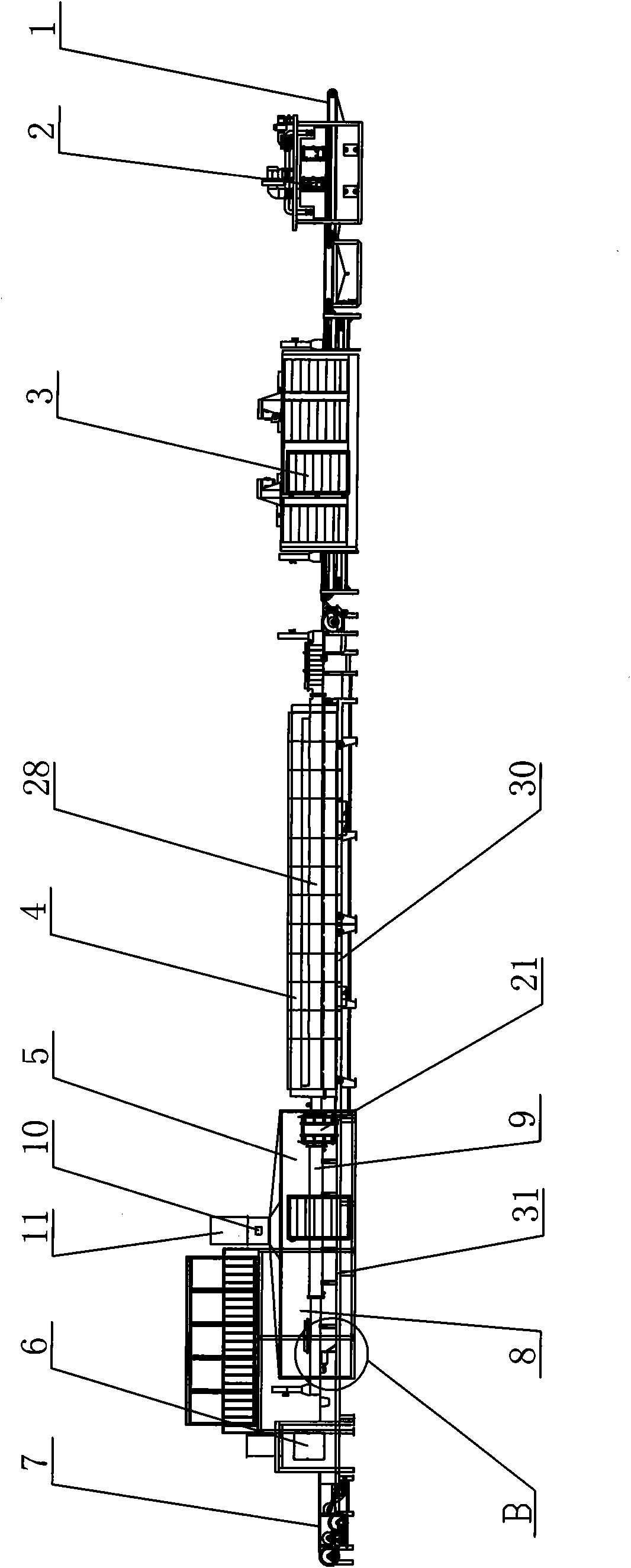

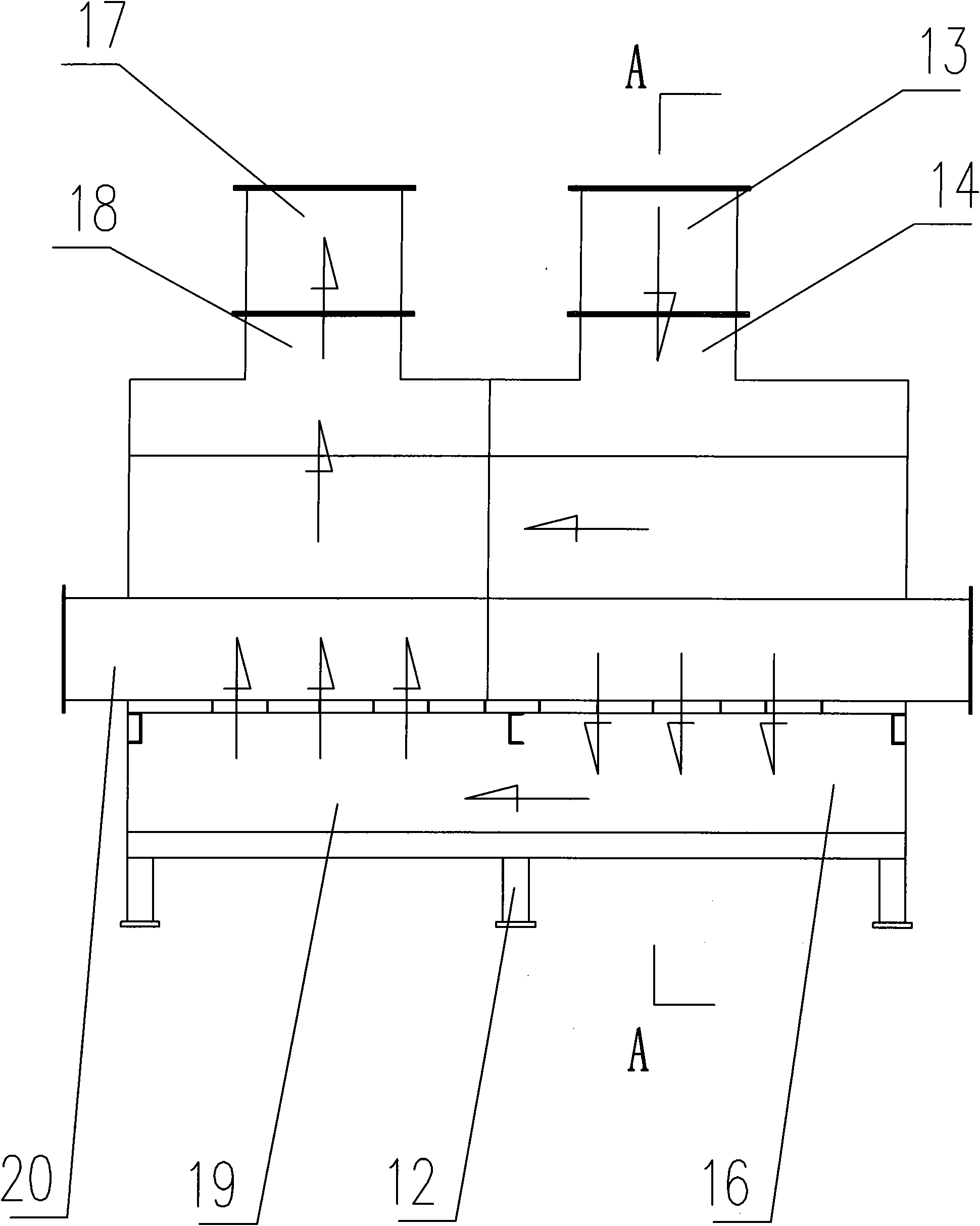

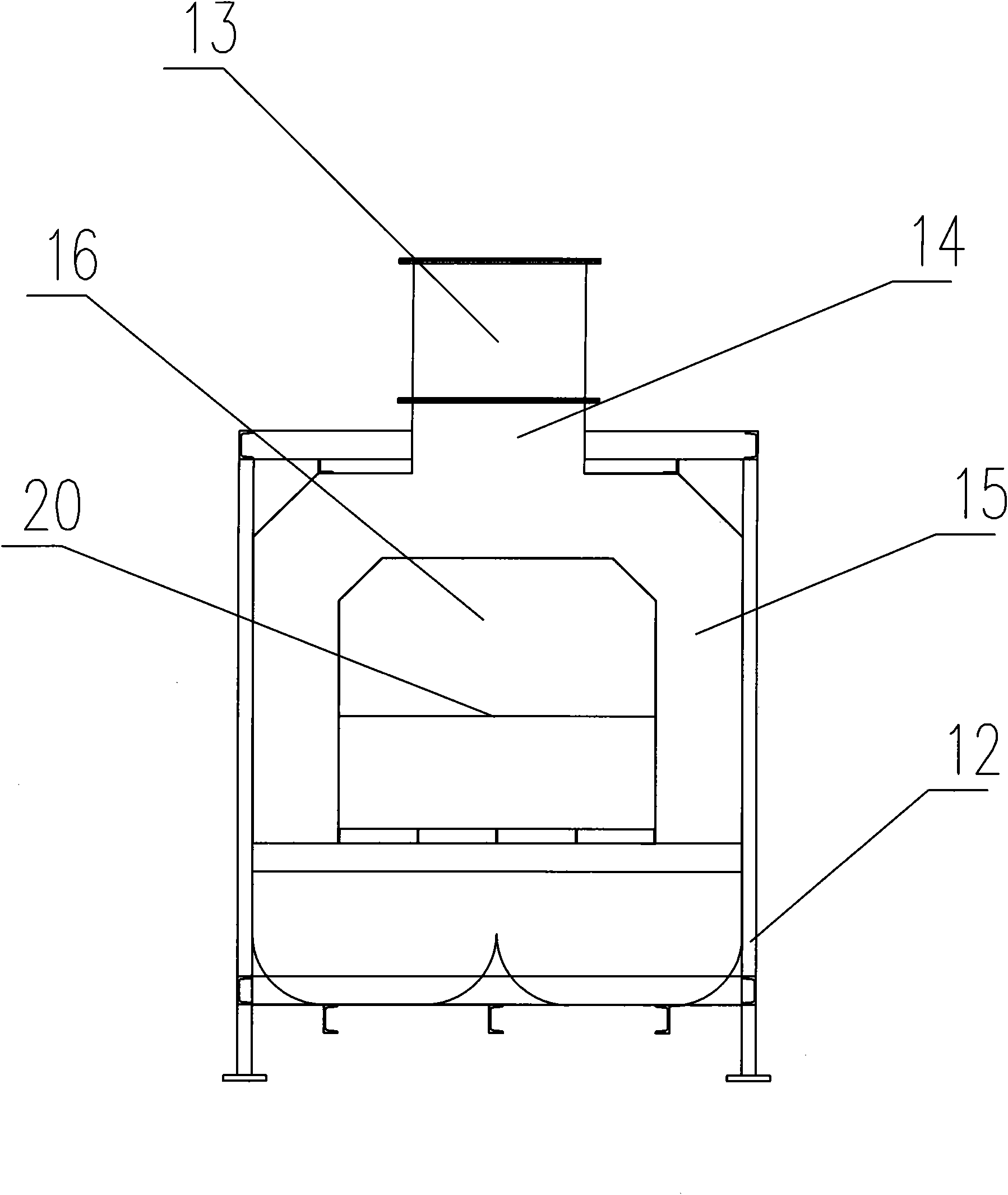

[0023] Such as figure 1 As shown, the aluminum brazing furnace includes: an upper part area 1, a spray area 2, a drying area 3, a brazing area 4, a pre-cooling area 5, a strong cooling area 6 and a lower part area 7. The pre-cooling area 5 is an air-cooled structure, and its structure includes: an air-cooled chamber 8, a furnace 9 in the pre-cooling zone passes through the air-cooled chamber 8, and air inlets are arranged on both sides of the lower end of the air-cooled chamber 8, and in the air-cooled chamber The upper end of 8 is provided with circulation blower fan 10 and air outlet 11; The structure of described forced cooling zone 6 comprises: air chamber frame 12, on the side of air chamber frame 12, air inlet circulation fan 13 and air inlet 14 are arranged, in The lower air chamber frame 12 of the air inlet 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com