Z-shaped bending device for embossed thin aluminum sheet

A technology of bending device and thin aluminum plate, which is applied in the field of Z-shaped bending equipment, can solve the problems of low work efficiency and large dimensional error, and achieve the effects of reduced labor intensity, improved on-site management, and optimized stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

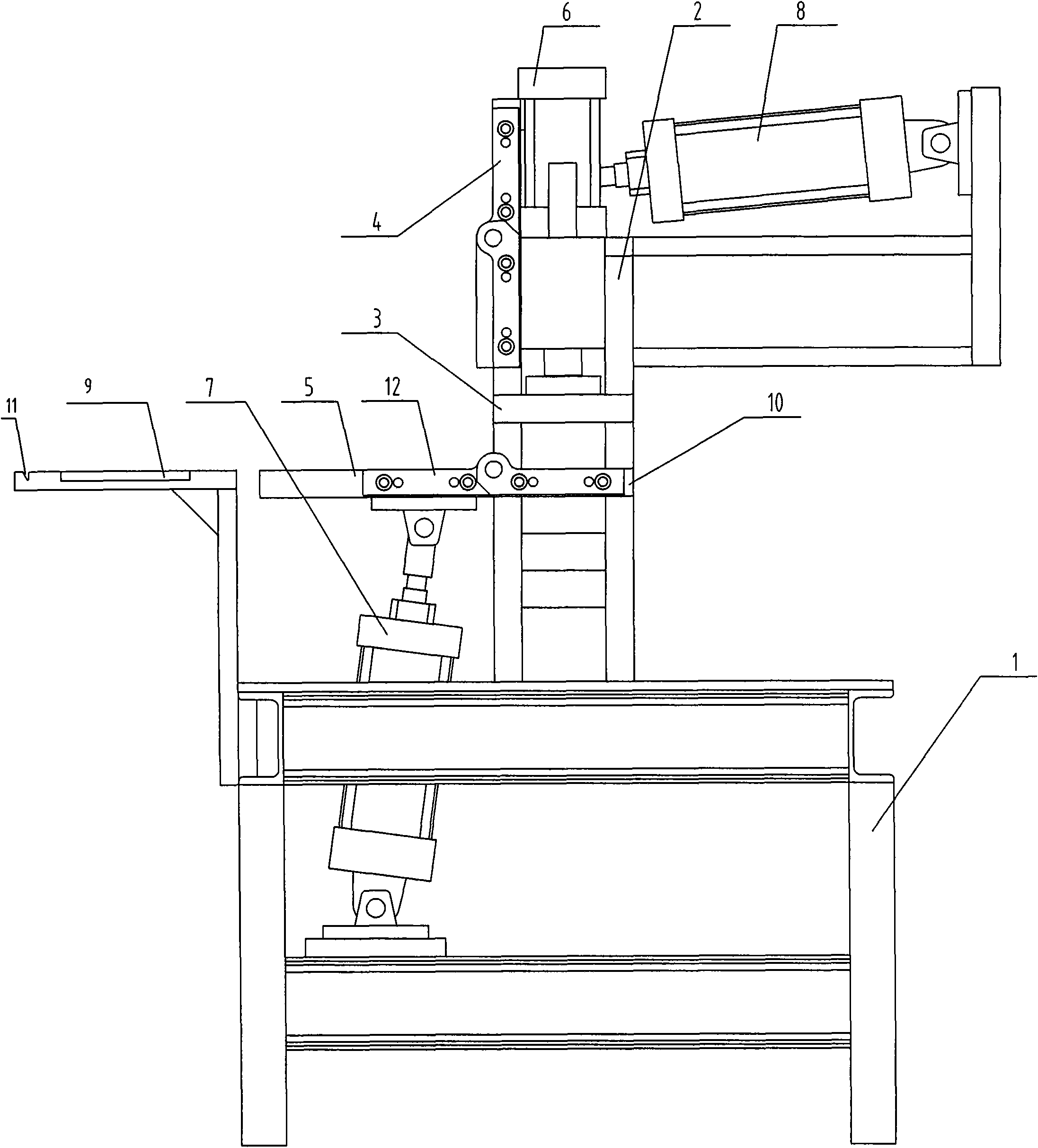

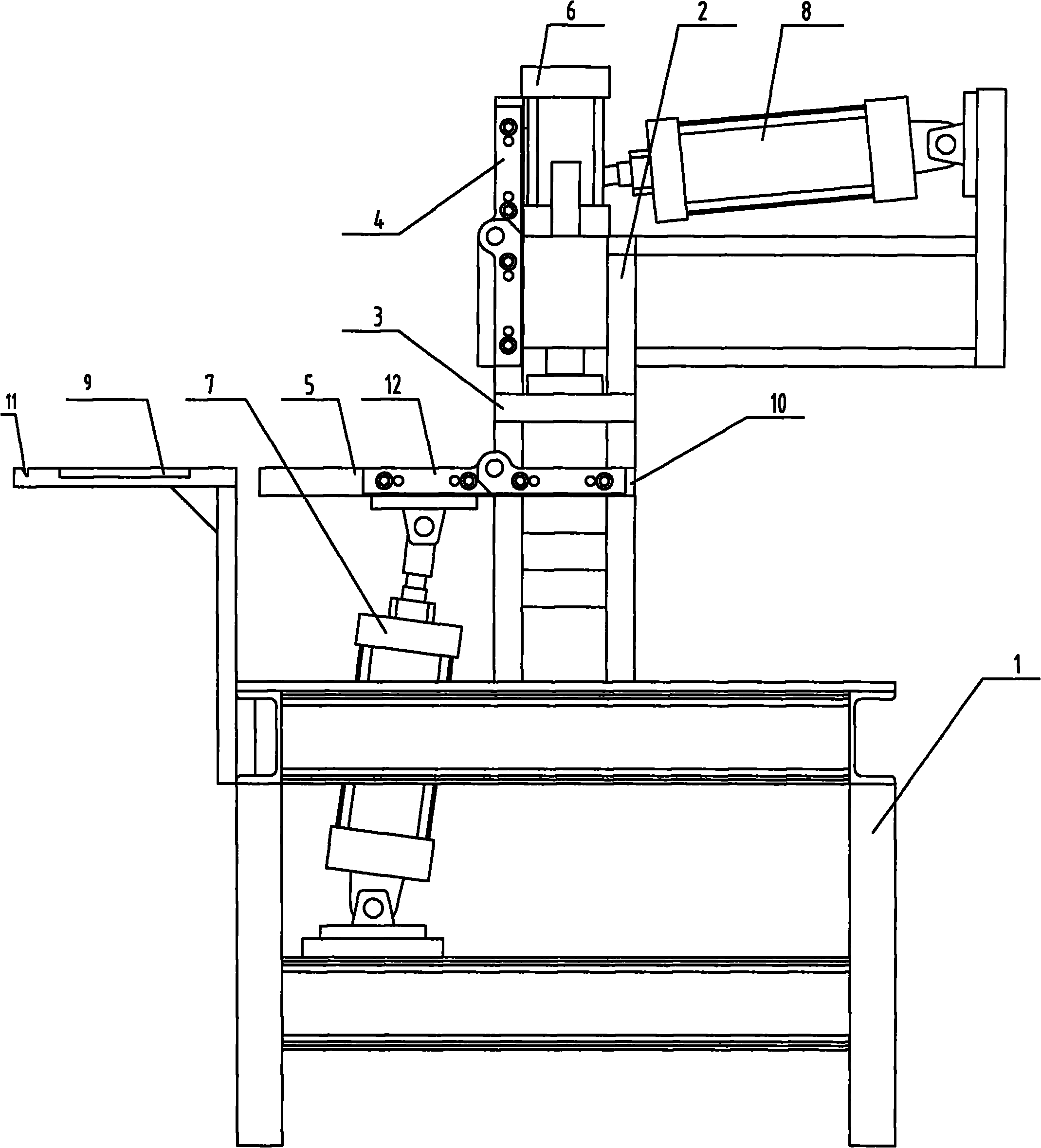

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention consists of a group of wallboard parts 2 and pressing plate 3 fixed on the bed 1, an upper turning plate 4, a lower turning plate 5, at least one pressing plate cylinder 6, two turning plate cylinders 7, 8, and a 30 The angle positioner 9 indicates the action of the cylinder through the program-controlled electrical components, and completes automatic pressing, turning down and turning up. Then reverse the flipping and loosening Z-shaped bending process in turn.

[0010] A base plate 10 is fixed above the bed 1, and a pressing plate 3 connected to the pressing plate cylinder 6 and capable of moving up and down is arranged above the base plate 10; The lower part is connected with a lower flap cylinder 7 that can turn the lower flap 5 upward; a locator 9 is arranged on the side of the lower flap 5; a vertically arranged upper flap 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com