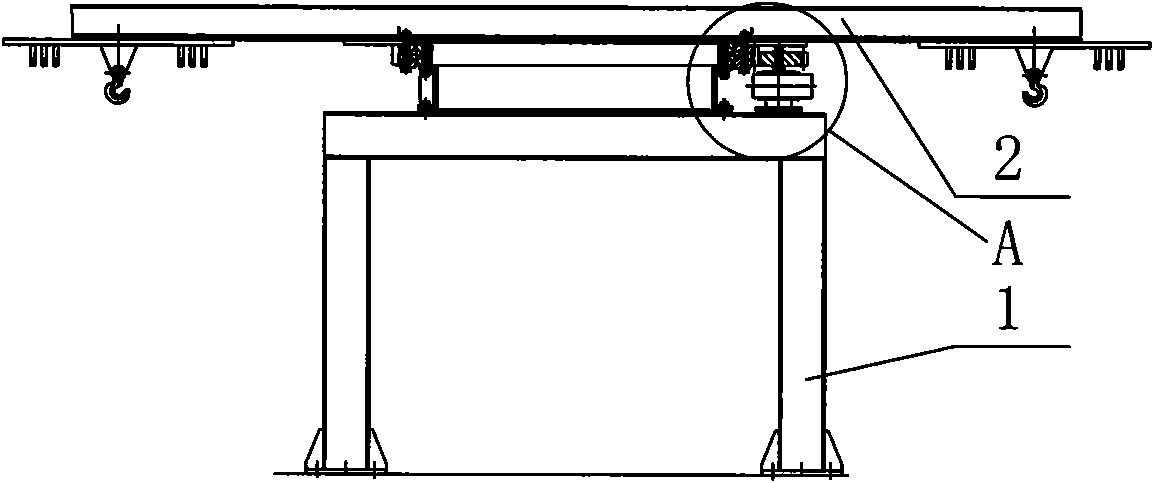

Rotary support driving mechanism in motor stator winding dipping lacquer system

A technology of slewing support and motor stator, which is used in electric components, manufacturing motor generators, electrical components, etc., can solve problems such as occupying a large production space, and achieve the effect of improving work efficiency, reducing labor costs, and saving production time costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

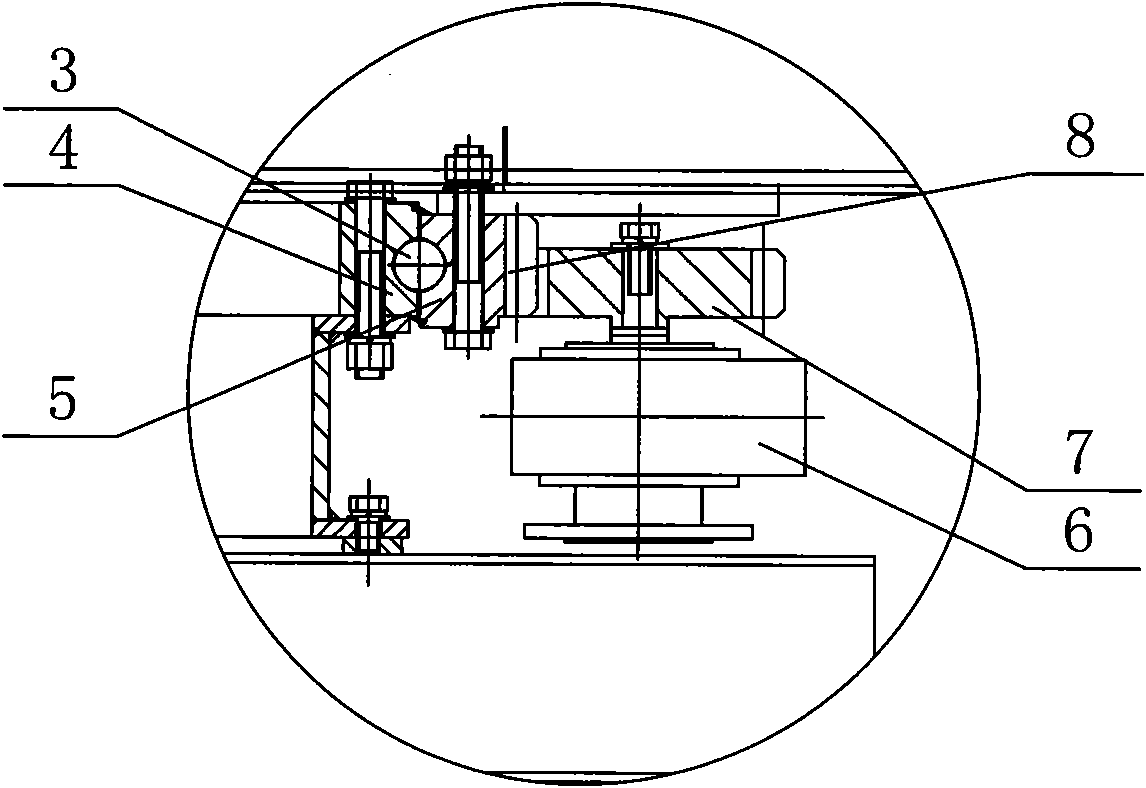

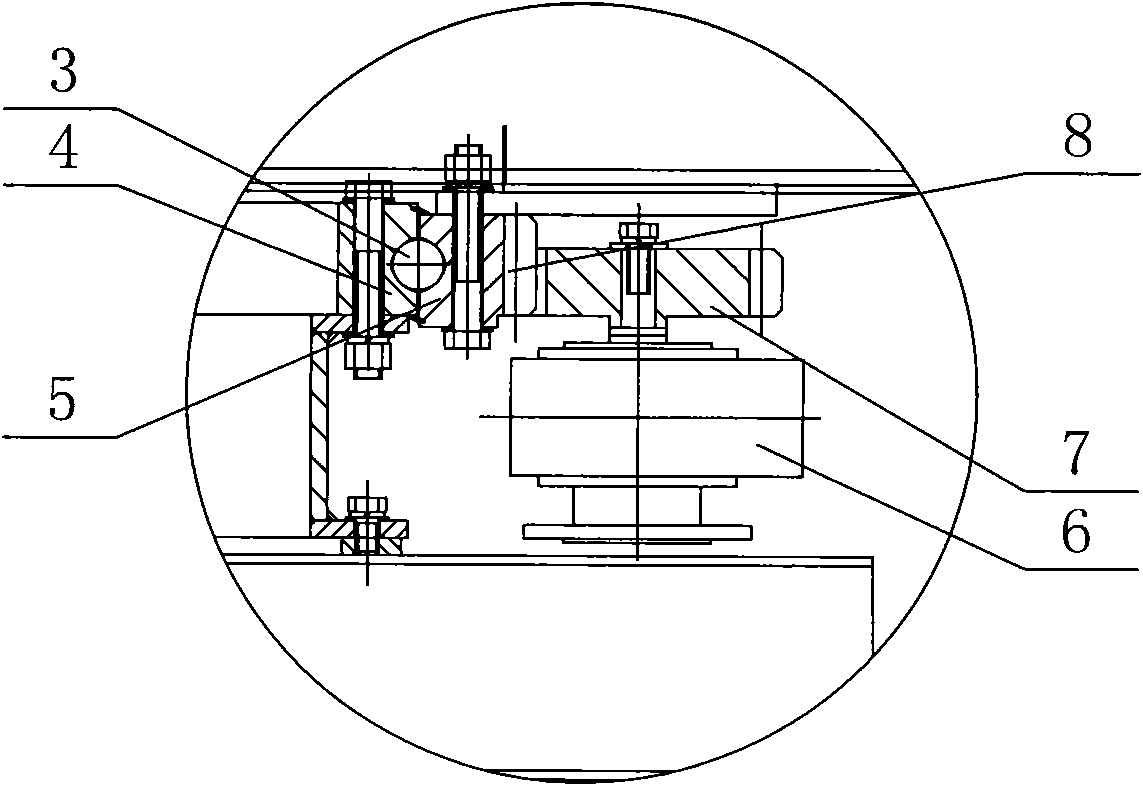

[0010] Such as Figure 1-2 As shown, the slewing support driving mechanism of the motor stator winding paint dipping system is applied between the center chassis 1 and the rotating platform 2. The center chassis 1 supports the rotating platform 2 through a slewing support, and the slewing support includes a ball ring 3, The inner fixing member 4 and the outer fixing member 5, and the inner fixing member 4 and the outer fixing member 5 are in a circular ring shape and are connected with each other. The connecting surface is circular and can be twisted to each other, and an annular circular cross section is formed on the connecting surface. The ball ring 3 is located in the circular cross section between the inner fixing member 4 and the outer fixing member 5. The inner fixing member 4 is fixed on the central chassis 1 and the outer fixing member 5 is fixed on the rotating platform 2 , The hobbing 8 is machined on the outside of the outer fixing member 5, and the gear 7 is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com