Automatic folding device and folding method for transport box

A technology of folding device and transport box, applied in the directions of transportation and packaging, packaging, conveyor objects, etc., can solve the problems of high cost, low efficiency and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

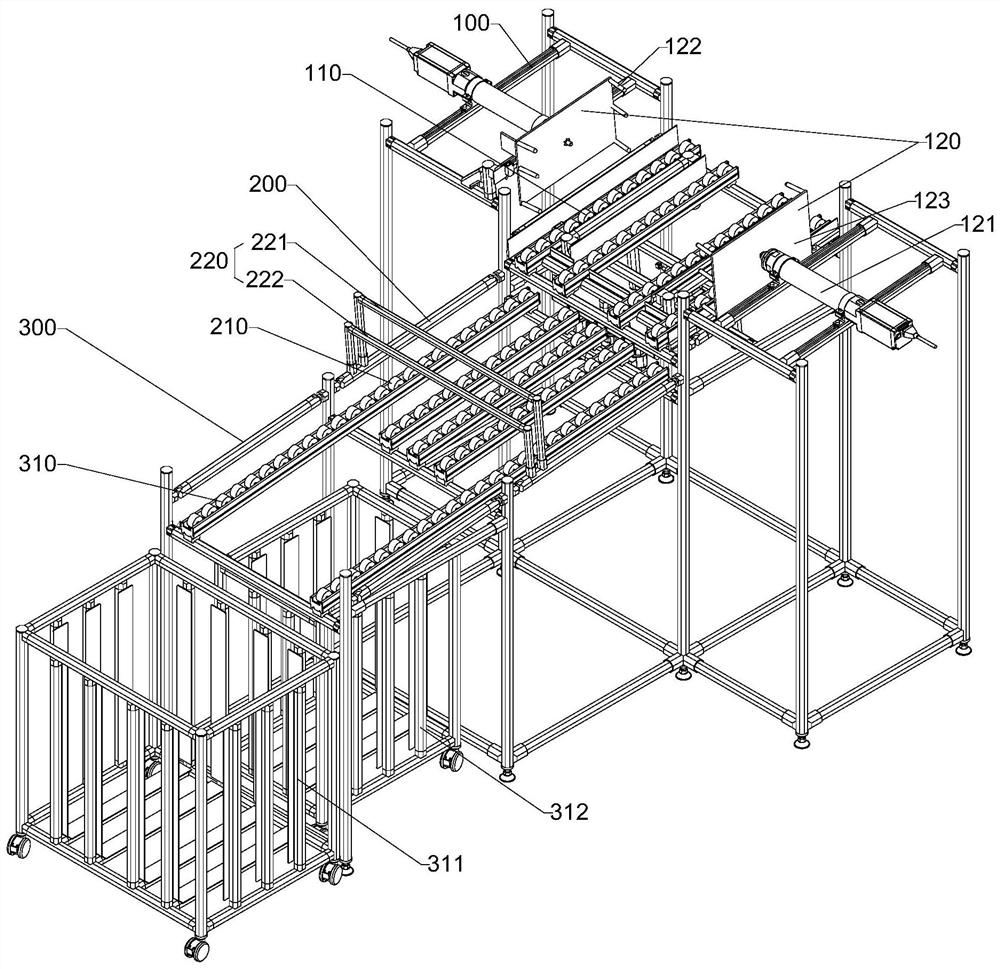

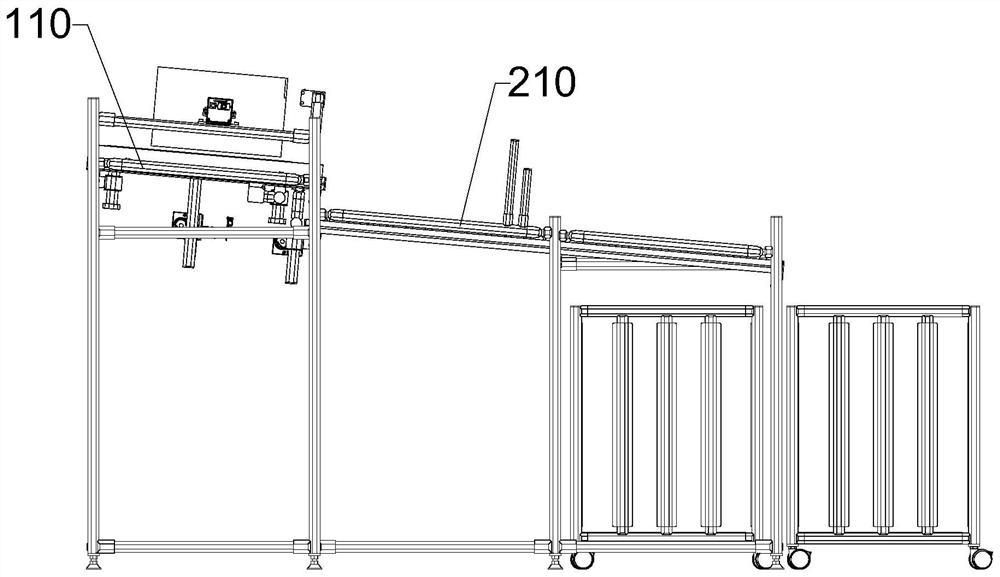

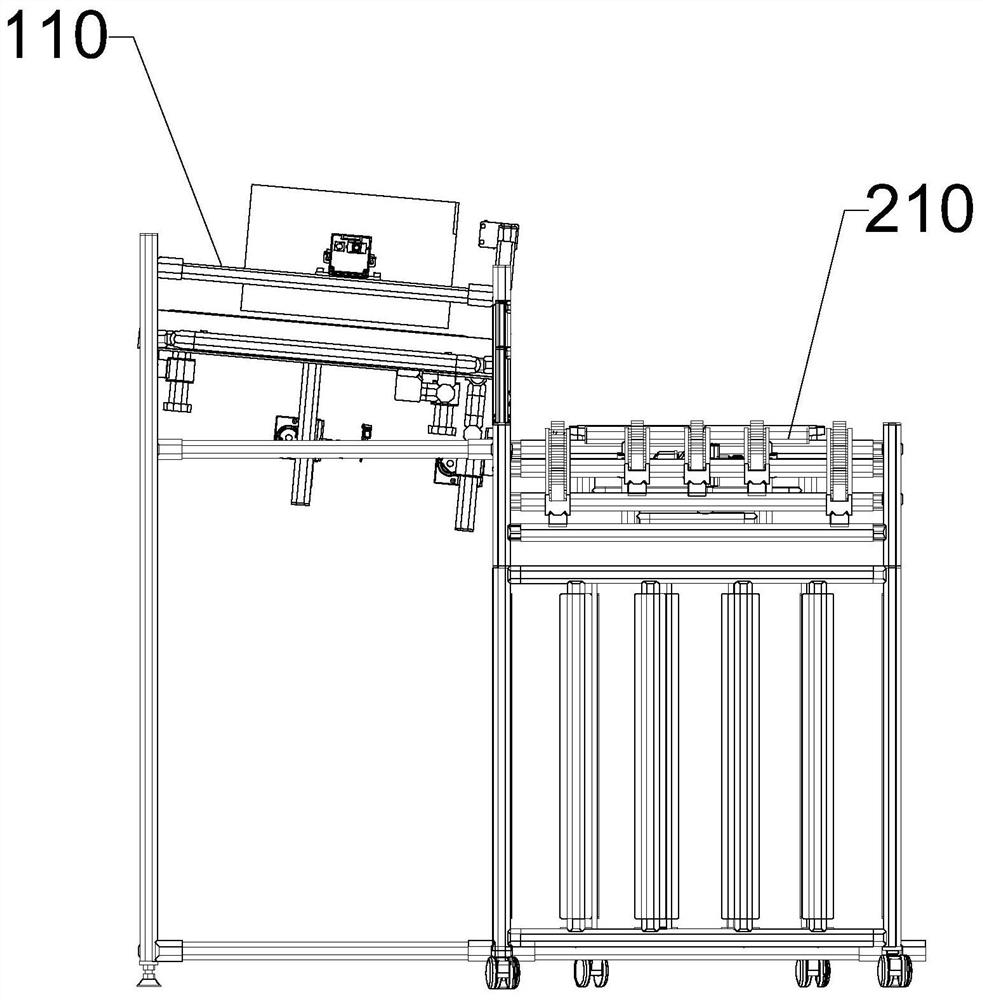

[0039] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention discloses an automatic folding device for a transport box, including: a first folding mechanism 100, the first folding mechanism 100 includes a first conveying roller bed 110 for transporting a transport box to be folded and for The first push rod assembly 120 that realizes the folding of the opposite sides of the transport case to be folded; the first push rod assembly 120 is arranged on both sides of the first conveying roller bed 110 along the transport direction of the transport case to be folded; and is arranged on the The second folding mechanism 200 downstream of the first folding mechanism 100, the second folding mechanism 200 includes a second delivery roller bed 210 and a second folding member 220 for receiving the transport box folded by the first folding mechanism 100 , the second conveying roller bed 210 and the first conveying roller bed 110 are vertically spaced apart; The side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com