Rotation supporting structure of electric machine stator winding paint-dipping system

A technology of slewing support and motor stator, applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of occupying a large production space, achieve the effects of improving work efficiency, reducing labor costs, and saving production time and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

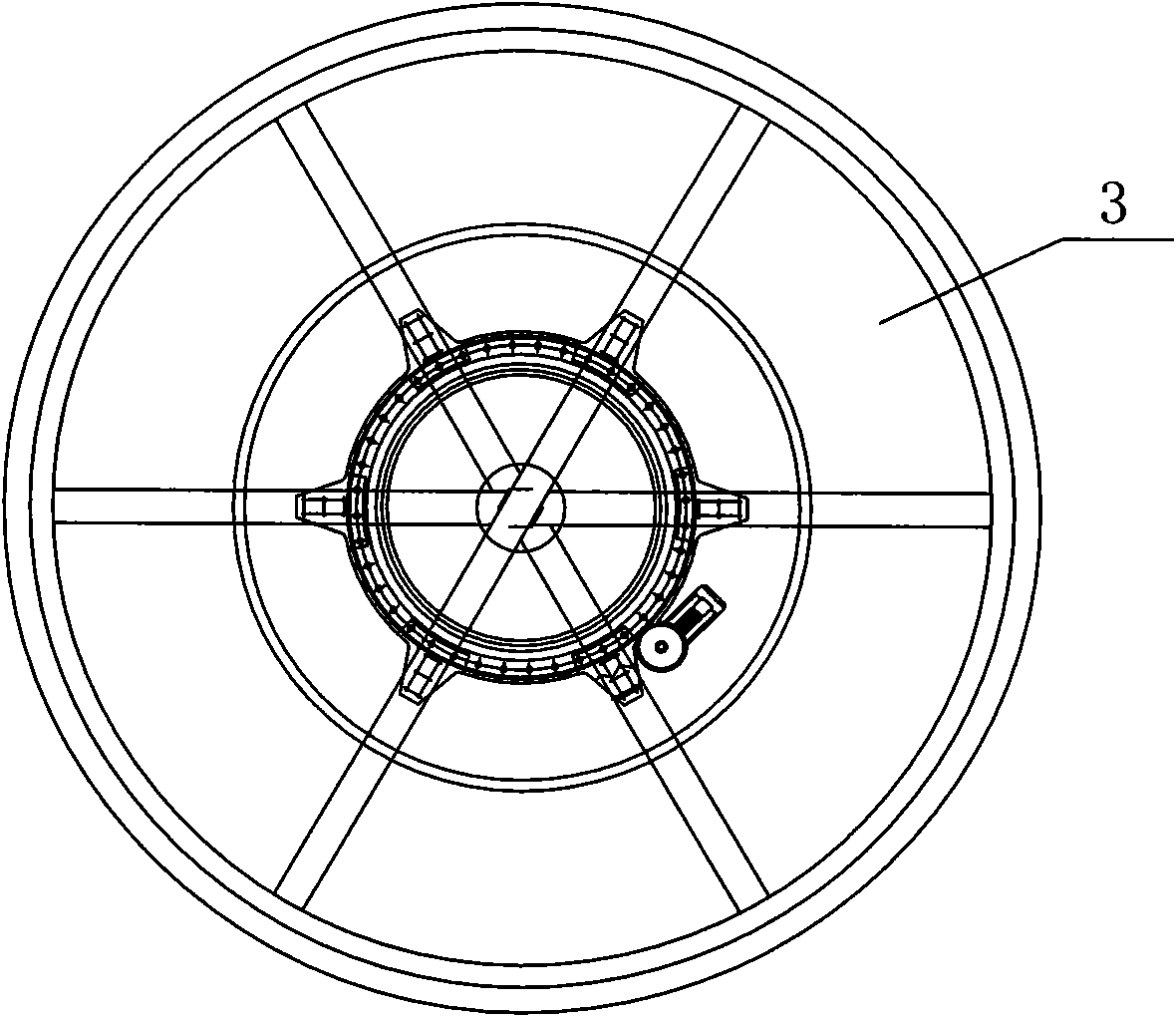

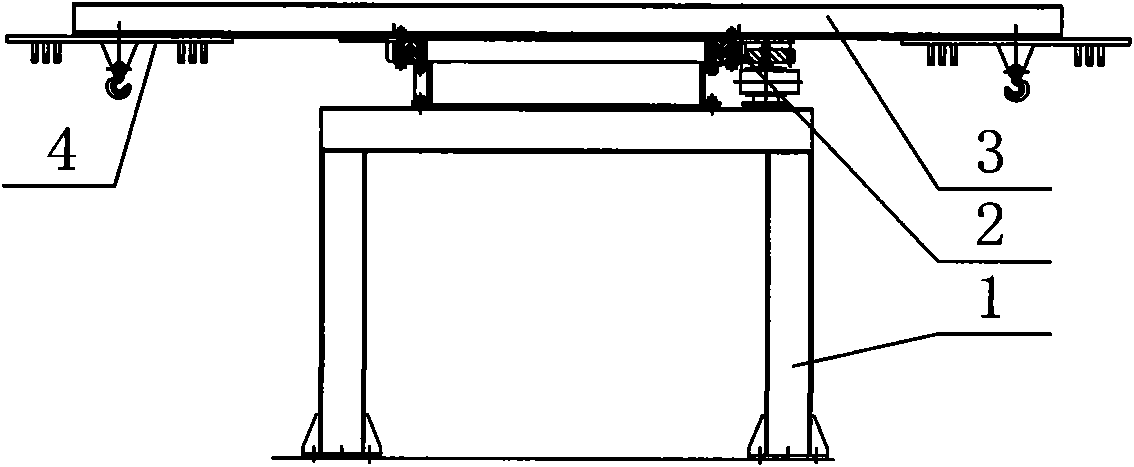

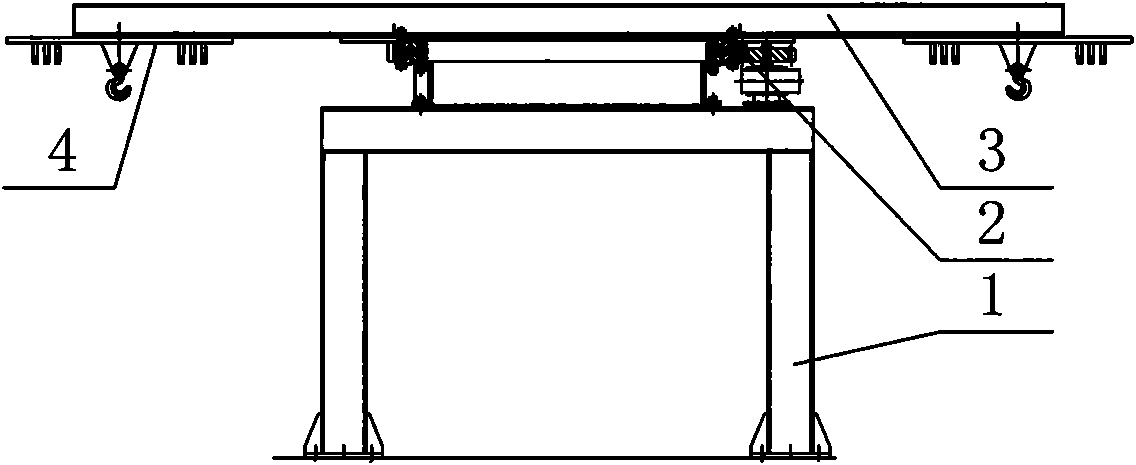

[0010] like Figure 1-2 As shown, the rotary support structure of the motor stator winding dipping system includes a center chassis 1 located in the center for support, and a rotary platform 3 is supported by a rotary support 2 on the center chassis 1. The rotary platform 3 is circular. Several stations are evenly arranged on the rotating platform 3 .

[0011] The present invention is a rotary support structure of a motor stator winding paint dipping system, which is designed as a center rotary support structure, so that various processes can be carried out sequentially according to the circular rotary structure. The motor stator winding impregnation system can solve the problem that a single product is idle between the two process links, which in turn leads to the problem that the storage and stacking of unfinished products will occupy a large production space. It can make multiple process links of impregnation paint in The cycle is carried out sequentially on one piece of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com