Method for remotely monitoring and controlling hydraulic support on underground working surface

A technology of hydraulic support and implementation method, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as remote control, and achieve the effects of complete content information, high reliability, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

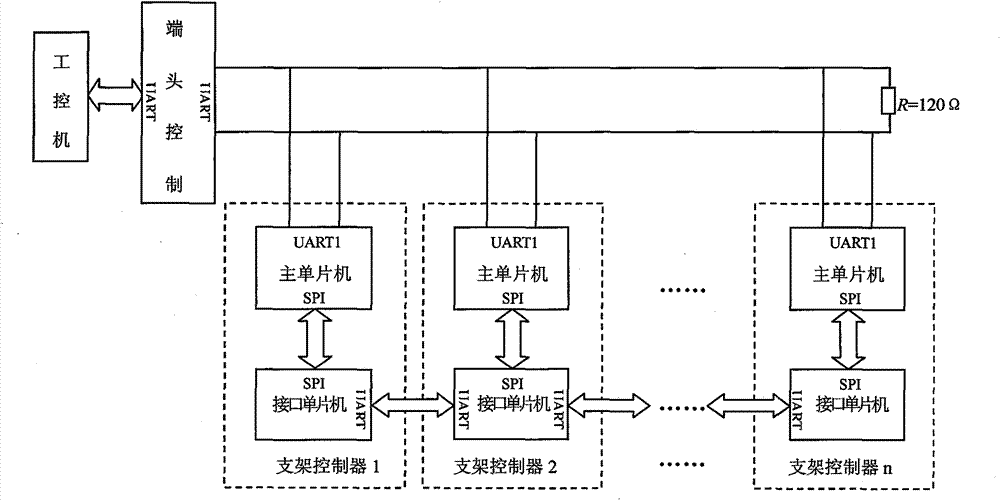

[0023] Below in conjunction with the accompanying drawings, a further detailed description of the implementation method for the remote monitoring and control of the hydraulic support of the underground working face of the coal mine is described in detail in conjunction with the accompanying drawings. The hydraulic terminal controller, combined with the existing technology in this field and the application of corresponding software, can realize the electro-hydraulic remote monitoring and control method of the hydraulic support described in the present invention, and can also realize the positive effects described in the present invention.

[0024] The method of the invention adopts the PowerBuilder tool as the front-end development platform to realize the electro-hydraulic remote control of the hydraulic support of the coal mine unattended working face. Its specific implementation method is as follows:

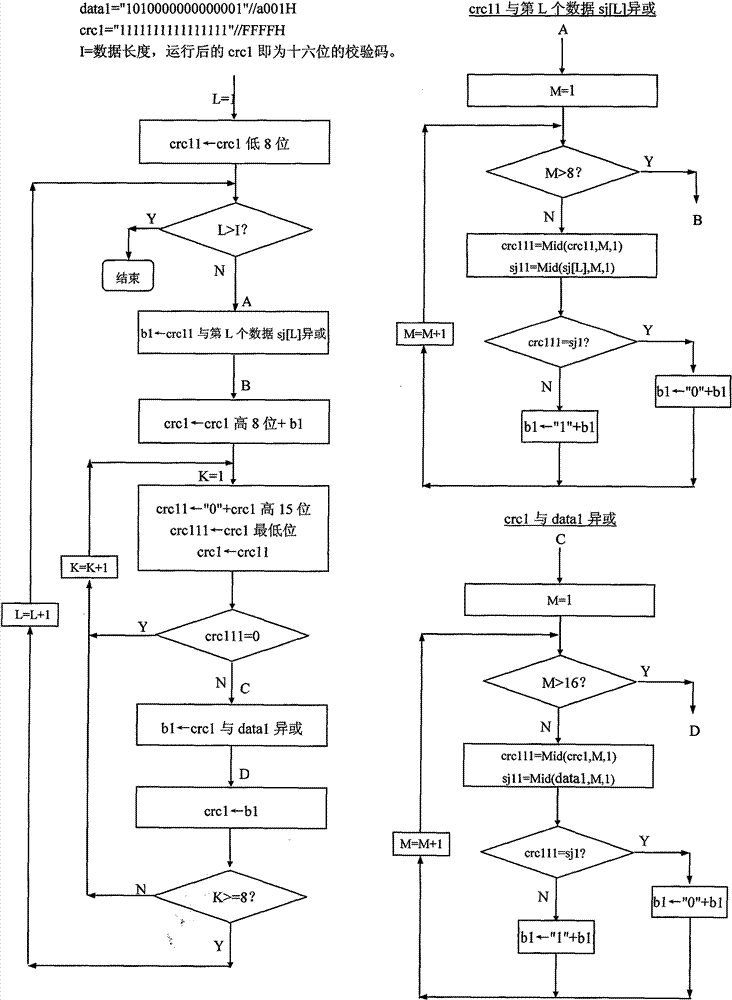

[0025] 1. Remote transmission method of hydraulic support control paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com