Wire rope-free jointing device of water injection well measurement adjuster

A docking device, measuring and adjusting instrument technology, applied in the direction of measurement, wellbore/well components, mining fluid, etc., can solve the problems of easy interference of steel wire rope, easy damage of steel wire rope, high cost, etc., and achieve great flexibility, easy production and processing, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

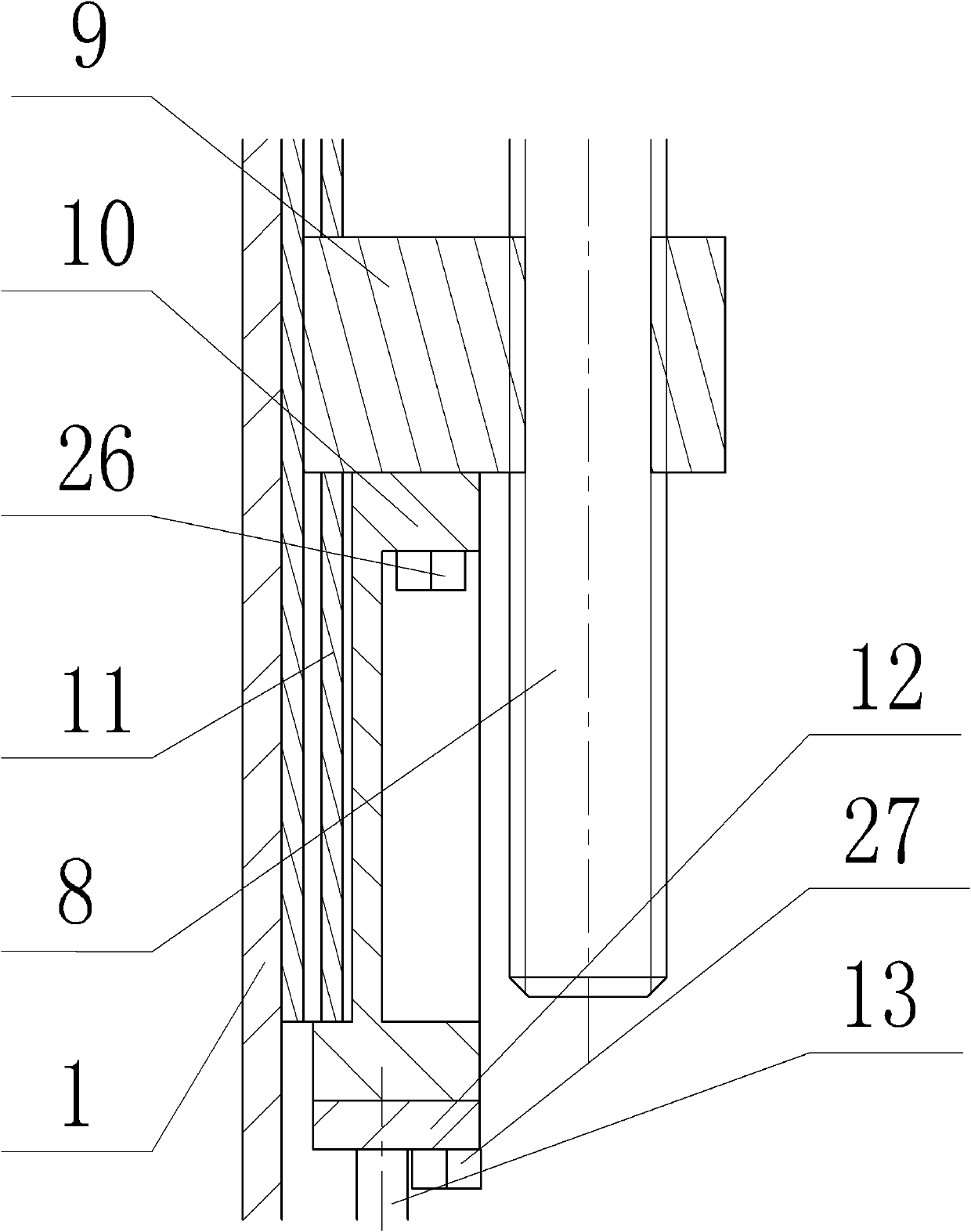

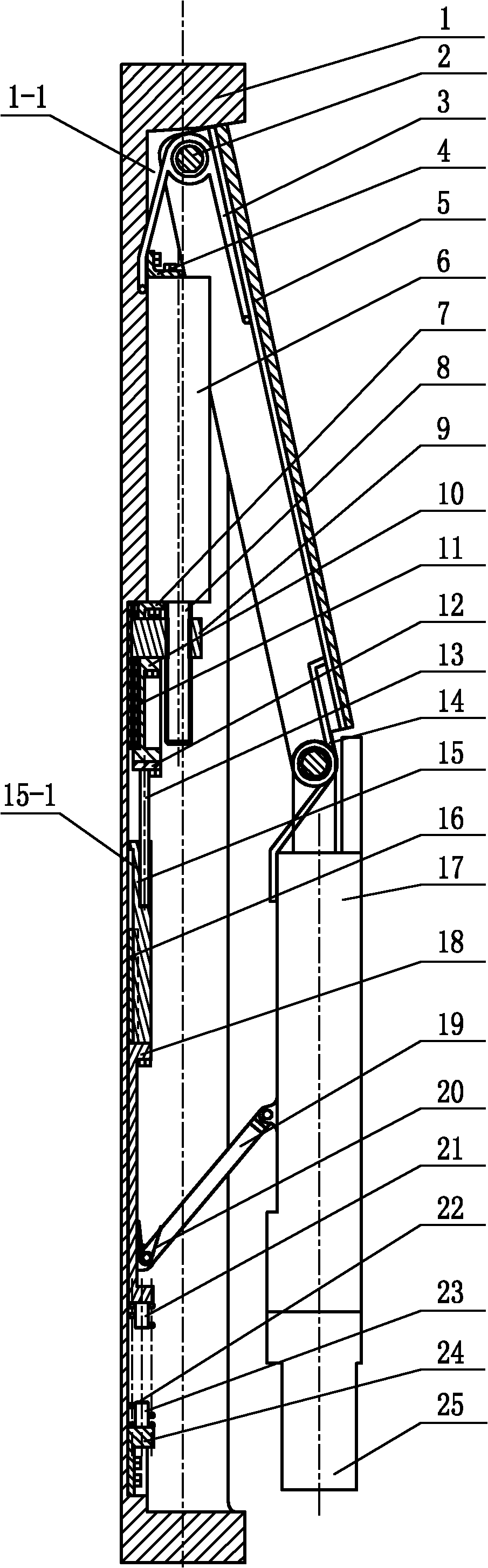

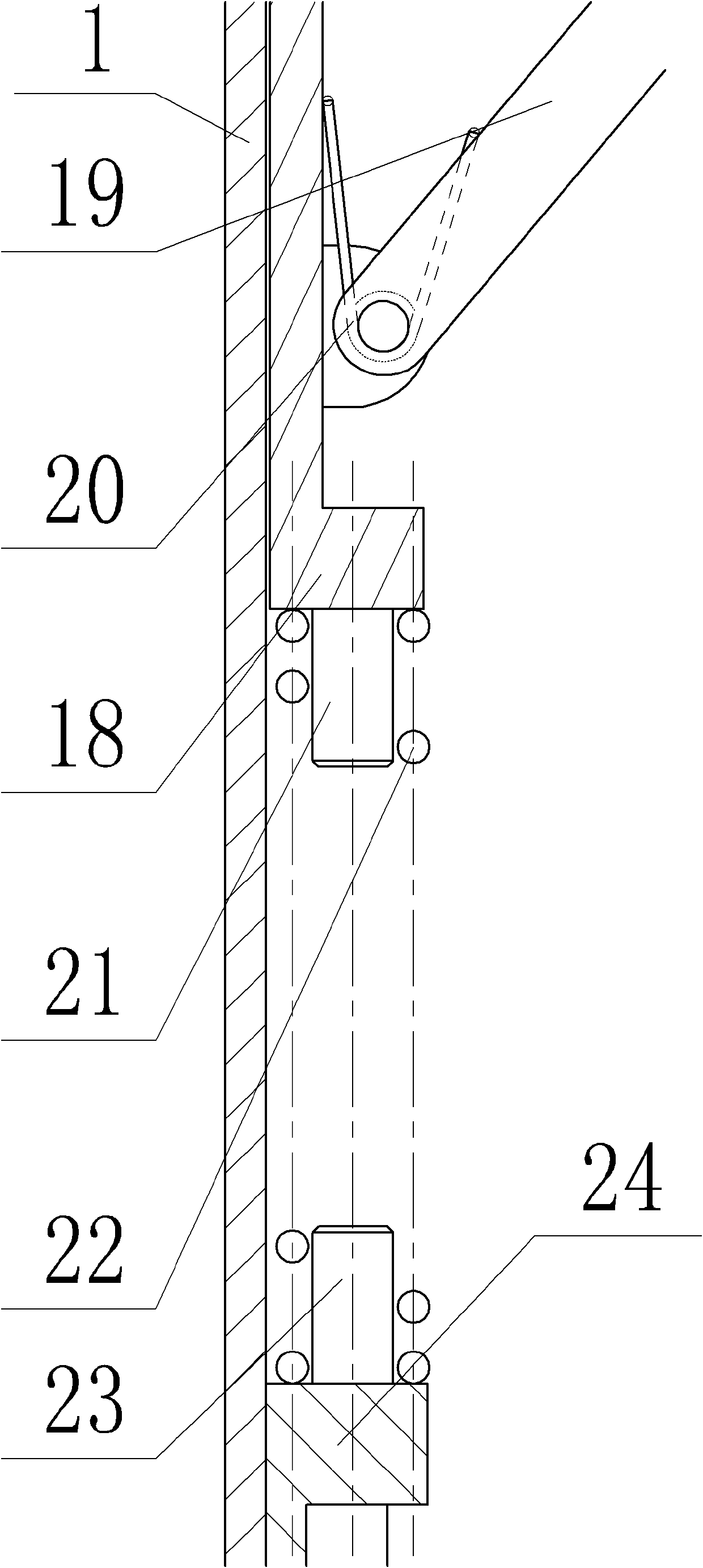

[0008] Specific implementation mode one: combine Figure 1~4 Describe this embodiment. The cordless docking device of the water injection well measuring and adjusting instrument described in this embodiment includes a base body 1, a motor assembly 6, a docking arm pop-up retracting mechanism, and a docking arm. The cavity 1-1 of the retracting mechanism and the docking arm, the motor assembly 6 drives the movement of the pop-up retracting mechanism of the docking arm to realize the pop-up and retracting actions of the docking arm; the pop-up retracting mechanism of the docking arm includes a lead screw 8, a nut 9, a push rod 13. Slider 15, push rod 18, connecting rod 19, small torsion spring 20 and coil spring 22; the docking arm includes upper torsion spring 3, pop-up arm 5, lower torsion spring 14 and measuring and adjusting motor sleeve 17; motor assembly 6 is located on the upper part of the cavity 1-1 and fixed on the side wall of the cavity 1-1, the lead screw 8 is locat...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 with 2 To illustrate this embodiment, the ejection and retraction mechanism of the docking arm in this embodiment also includes an upper dovetail groove 11, the upper dovetail groove 11 is installed on the inner side wall of the cavity 1-1, and the nut 9 can be mounted on the upper dovetail groove 11 slide up and down. The upper dovetail groove 11 is fixed on the base body 1 with screws, and the nut 9 cooperates with the upper dovetail groove 11 and can slide in the dovetail groove. Such arrangement ensures that the nut 9 runs smoothly. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 with 3 To illustrate this embodiment, the pop-up and retracting mechanism of the docking arm in this embodiment also includes a lower dovetail groove 16, the lower dovetail groove 16 is installed on the inner side wall of the cavity 1-1, and the slider 15 can be mounted on the lower dovetail groove Slide up and down within 16. The lower dovetail groove 16 is fixed on the base body 1 with screws, and the sliding block 15 cooperates with the lower dovetail groove 16 to freely slide in the dovetail groove. This arrangement ensures that the sliding block 15 runs smoothly. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com