Linear narrow grate gutter inlet grating

A technology for gutters and grates, applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of wasting grate raw materials, easily congested grate holes, and affecting drainage effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

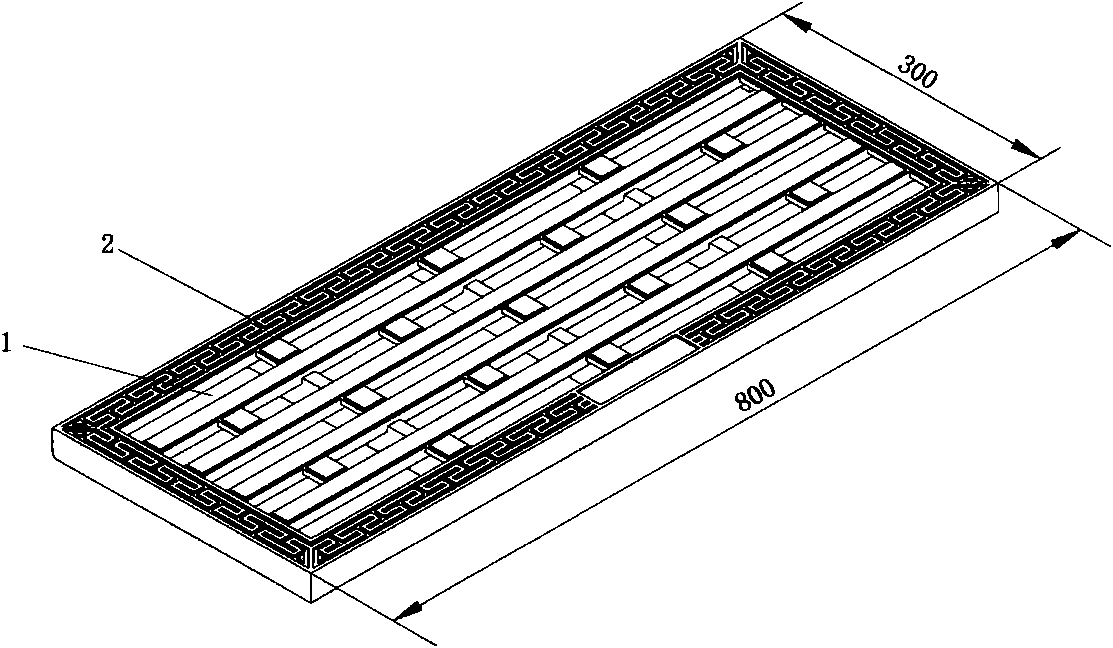

[0015] Such as figure 1 The linear narrow gully grate shown has a cuboid frame structure, and the inside of the cuboid frame has grid-shaped grate holes 1. The width of the grate is 170 mm, the length is 680 mm, and the ratio of width to length is 0.25. The upper surface of the grate is provided with a raised "back" pattern 2.

[0016] The water collection performance test was carried out on the aforementioned grate (narrow grate) and the 680×380 mm grate (wide grate). The test results are as follows:

[0017] Grating specification(mm)

[0018] In the aforementioned test experiments, the length of the grates was 680 mm. Since the water flow often can only pass through the grate holes on the side away from the curb, as the width of the grate increases, the water-passing width increases, but it cannot be compared with the grate. The width of the grate increases in the same proportion, and the water passing area does not expand significantly; at the same time, because ...

Embodiment 2

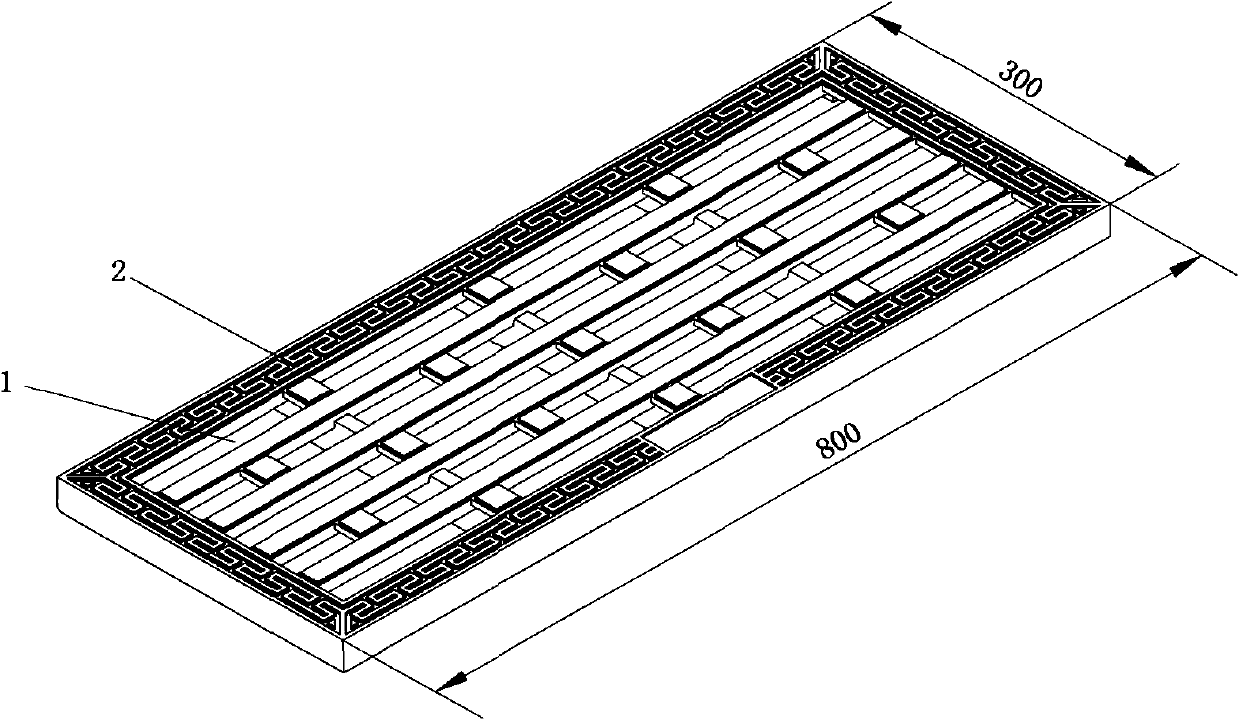

[0020] Such as figure 2 The linear narrow gully grate shown has a cuboid frame structure, and the inside of the cuboid frame has grid-shaped grate holes 1. The width of the grate is 300 mm, the length is 800 mm, and the ratio of width to length is 0.375. The upper surface of the grate is provided with a raised "back" pattern 2.

[0021] The water collection performance test was carried out on the aforementioned grate (narrow grate) and the 600×400 mm grate (wide grate). The test results are as follows:

[0022] Grating specification(mm)

[0023] In the aforementioned test experiments, the surface area of the grates is 0.24 square meters. Since the water flow can only pass through the grate holes on the side away from the curb, the water flow can flow through the entire surface area of the narrow grate, but not the entire surface area of the wide grate. . Although the water passing width of the wide grate is greater than that of the narrow grate, because the ...

Embodiment 3

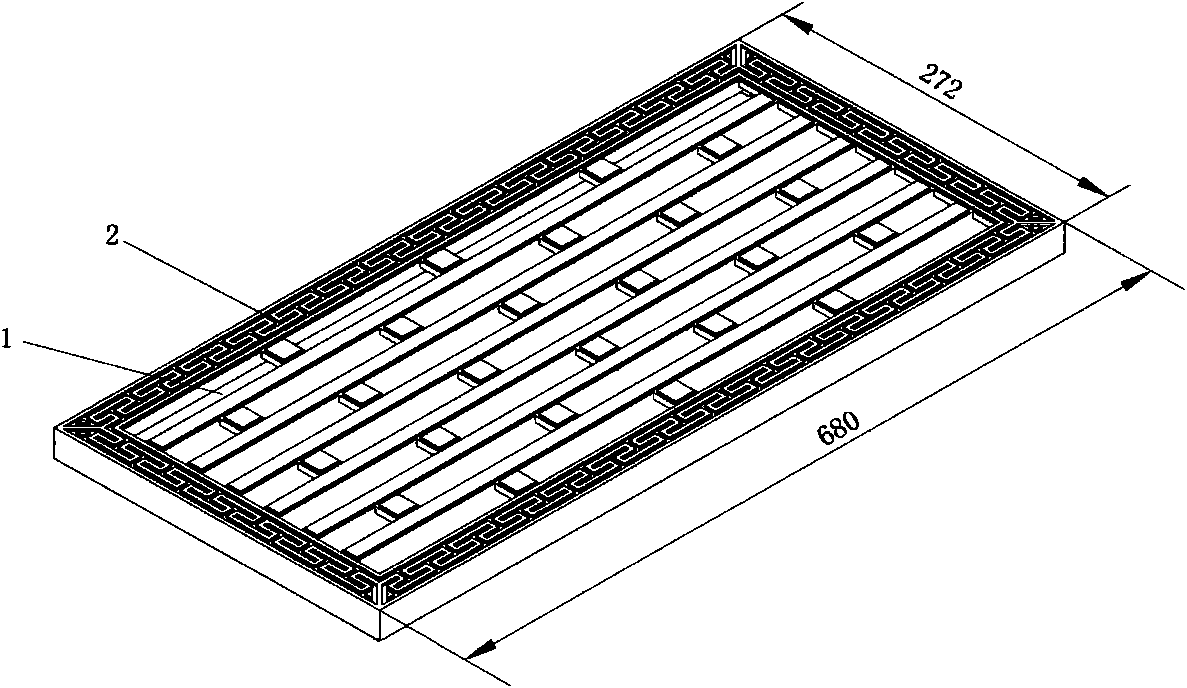

[0025] Such as image 3 The linear narrow gully grate shown has a cuboid frame structure, and the inside of the cuboid frame has grid-like grate holes 1, the width of which is 272 mm, the length is 680 mm, and the ratio of width to length is 0.4, the grate The upper surface is provided with a raised "back" pattern 2.

[0026] The water collection performance test was carried out on the aforementioned grate (narrow grate) and the 680×430 mm grate (wide grate). The test results are as follows:

[0027] Grating specification(mm)

[0028] In the above-mentioned test experiments, the length of the grates was 680 mm. Since the water flow can only pass through the grate holes on the side away from the curb, as the width of the grate increases, the water passing area does not increase significantly; The depth of the water flow is shallow, resulting in a smaller flow of the wide grate. It can be seen from the above experiments that the linear narrow grate can improve the ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com