Modular design method and structure of welding fixture for trial-manufacture sample vehicles

A modular design, welding fixture technology, applied in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of long design and production cycle, high production cost, strong speciality, etc., to shorten the design and production cycle, reduce Production cost, effect of simplified design method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

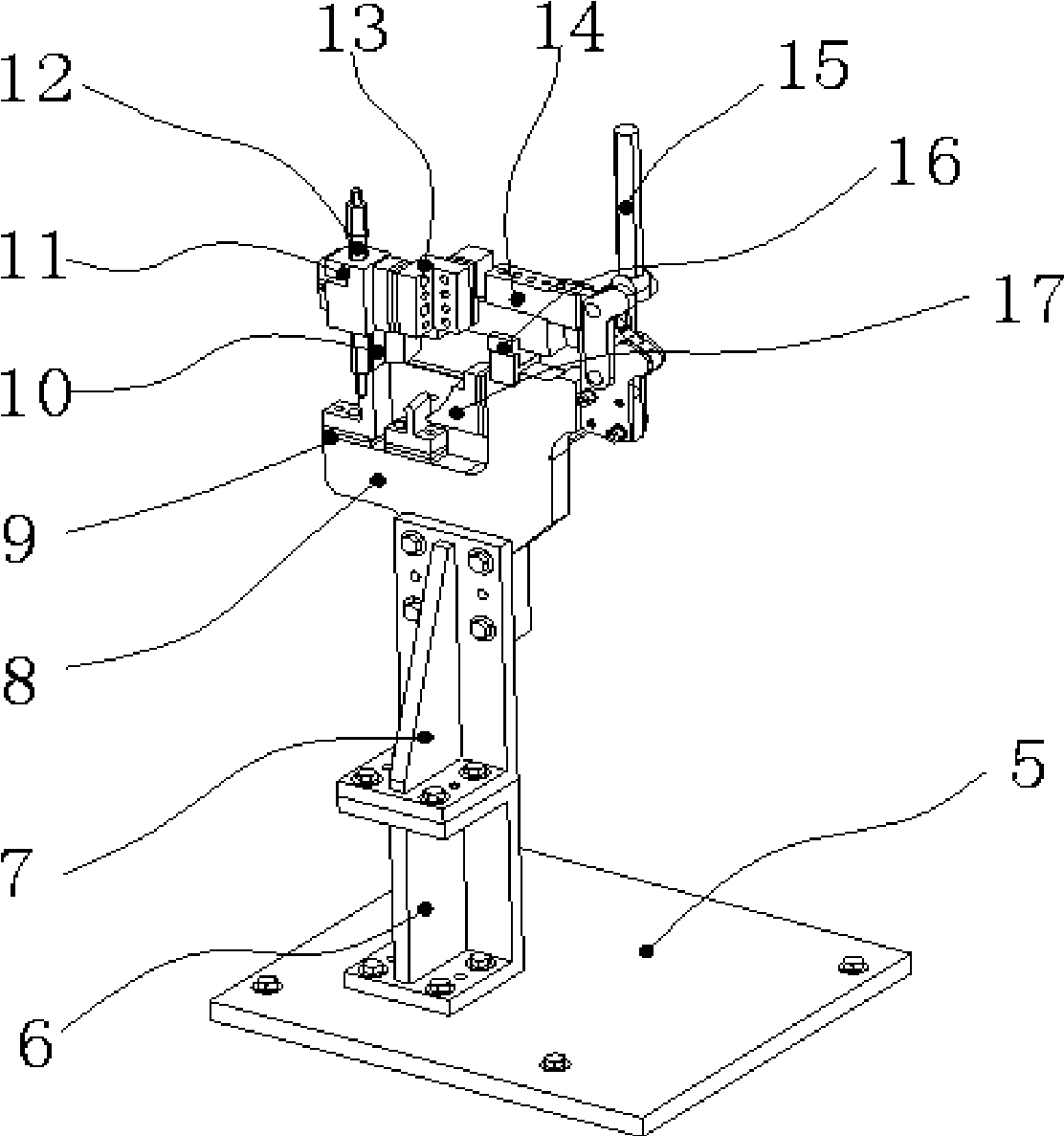

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

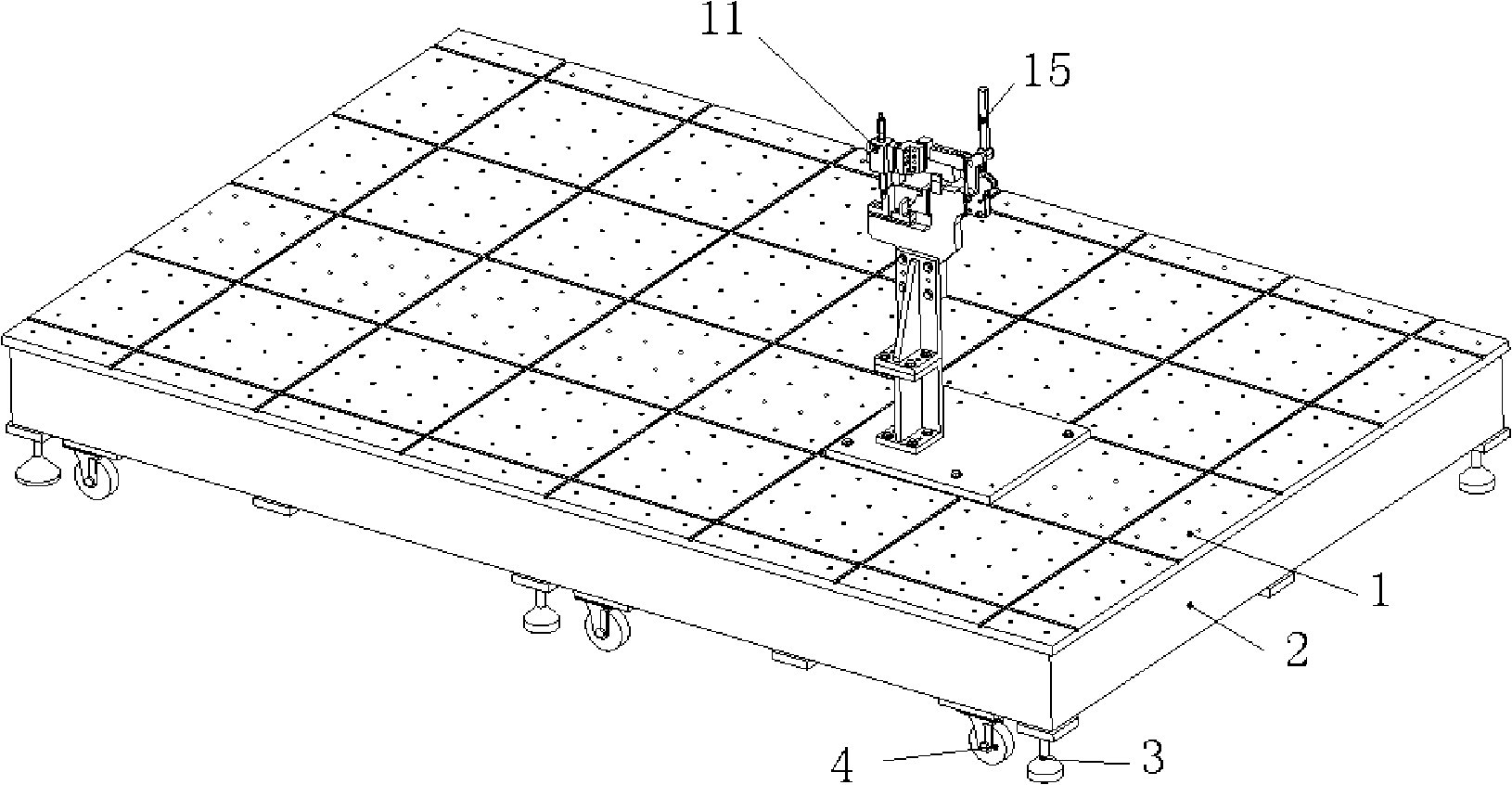

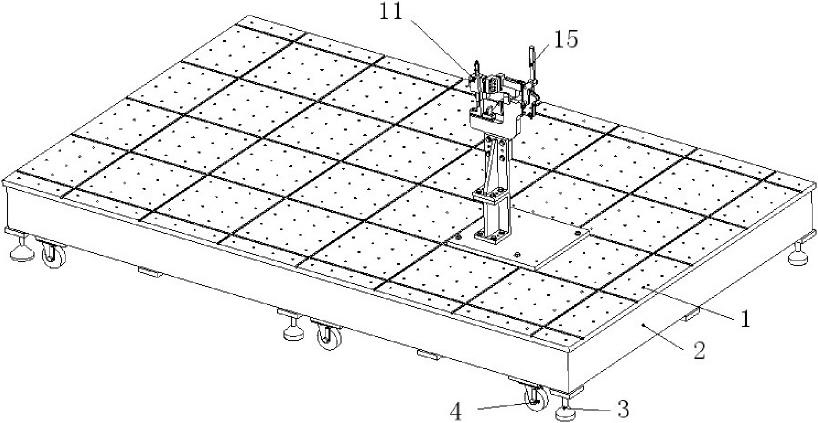

[0019] see figure 1 , figure 2 , the modular design of the trial prototype welding fixture in this embodiment includes two parts:

[0020] One is the base part, which is composed of base plate 1, frame 2, adjustment device 3, and casters 4. The base plate 1 is installed on the surface of the frame 2, and the base plate 1 is provided with 50mm equidistant screw holes. The distance between the screw holes is also equal, and casters 4 are respectively provided at the four corners of the bottom of the frame 2 and the middle frame position of the frame length direction, and an adjustment device 3 is adorned next to each caster wheel, which is used for adjusting the level of the frame 2. According to the workpiece to be welded, several base parts of different specifications are combined to form the whole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com