Can making machinery for curling openings and swelling bodies

A rolling mouth, mechanical technology, applied in other household appliances, household appliances, applications, etc., can solve the problems of high production cost and labor cost, inconvenient transportation and installation, increase production cost, etc., to achieve convenient transportation and installation, compact installation , control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following are only preferred embodiments of the present invention, and are not intended to limit the protection scope of the present invention.

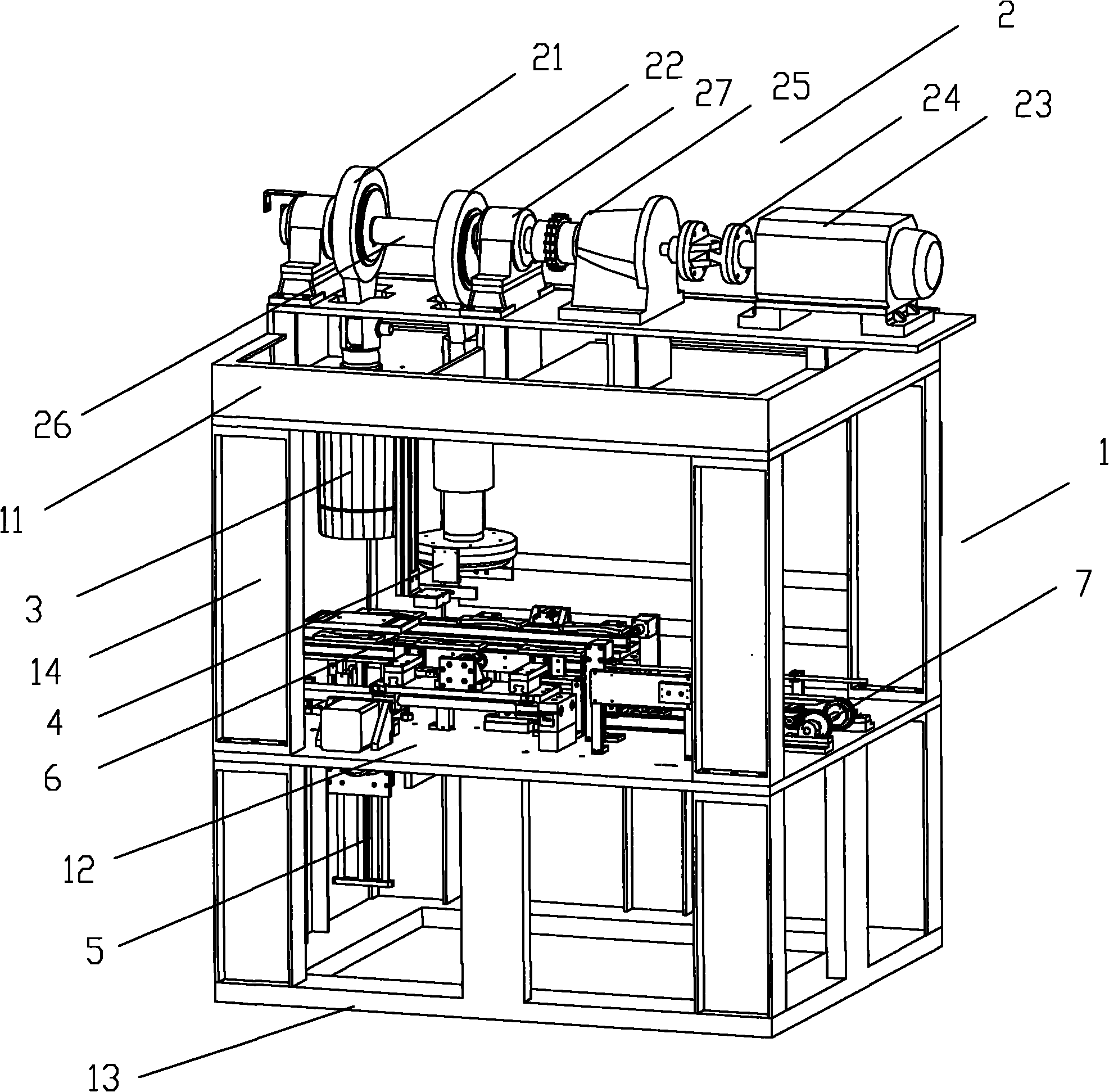

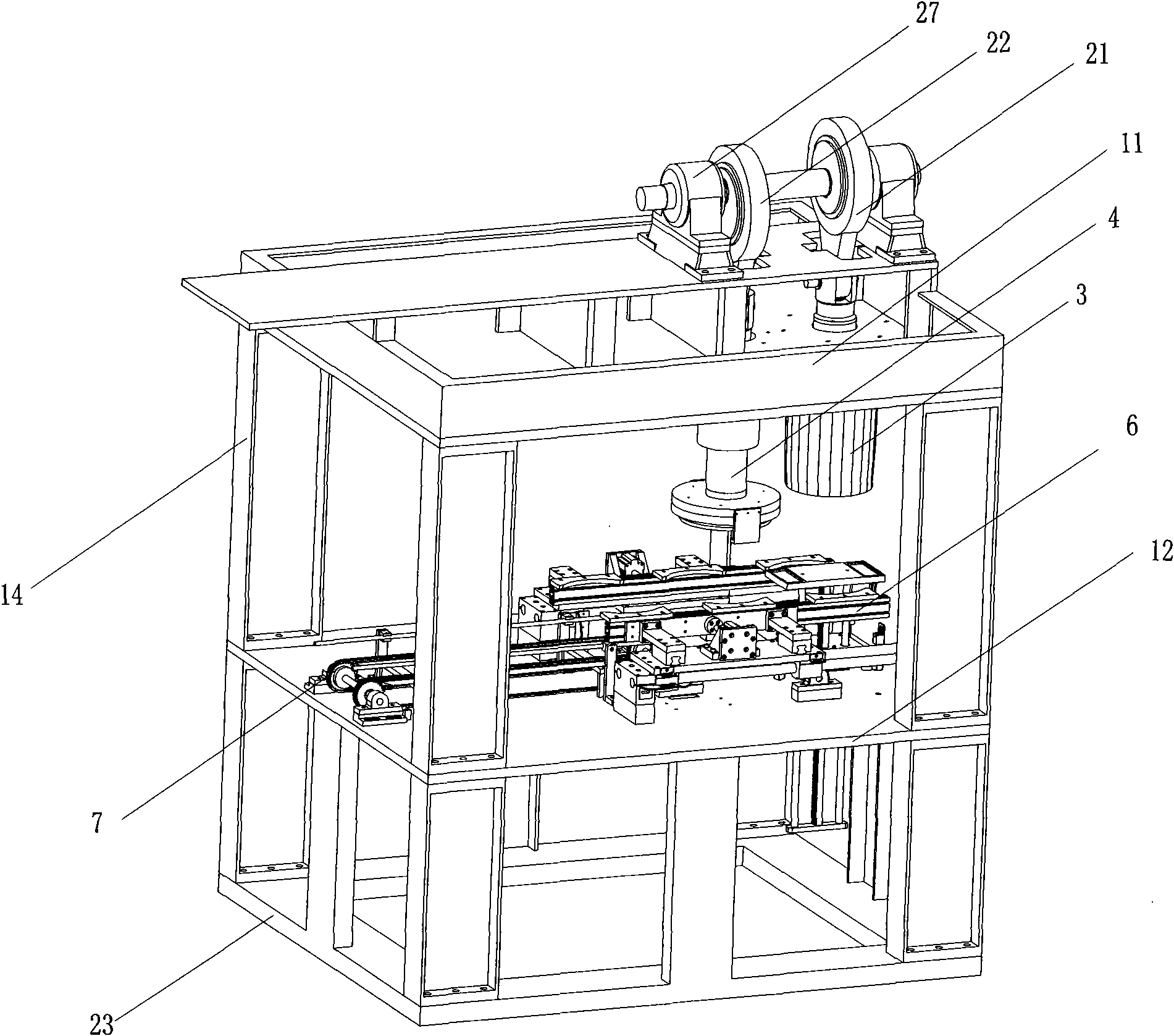

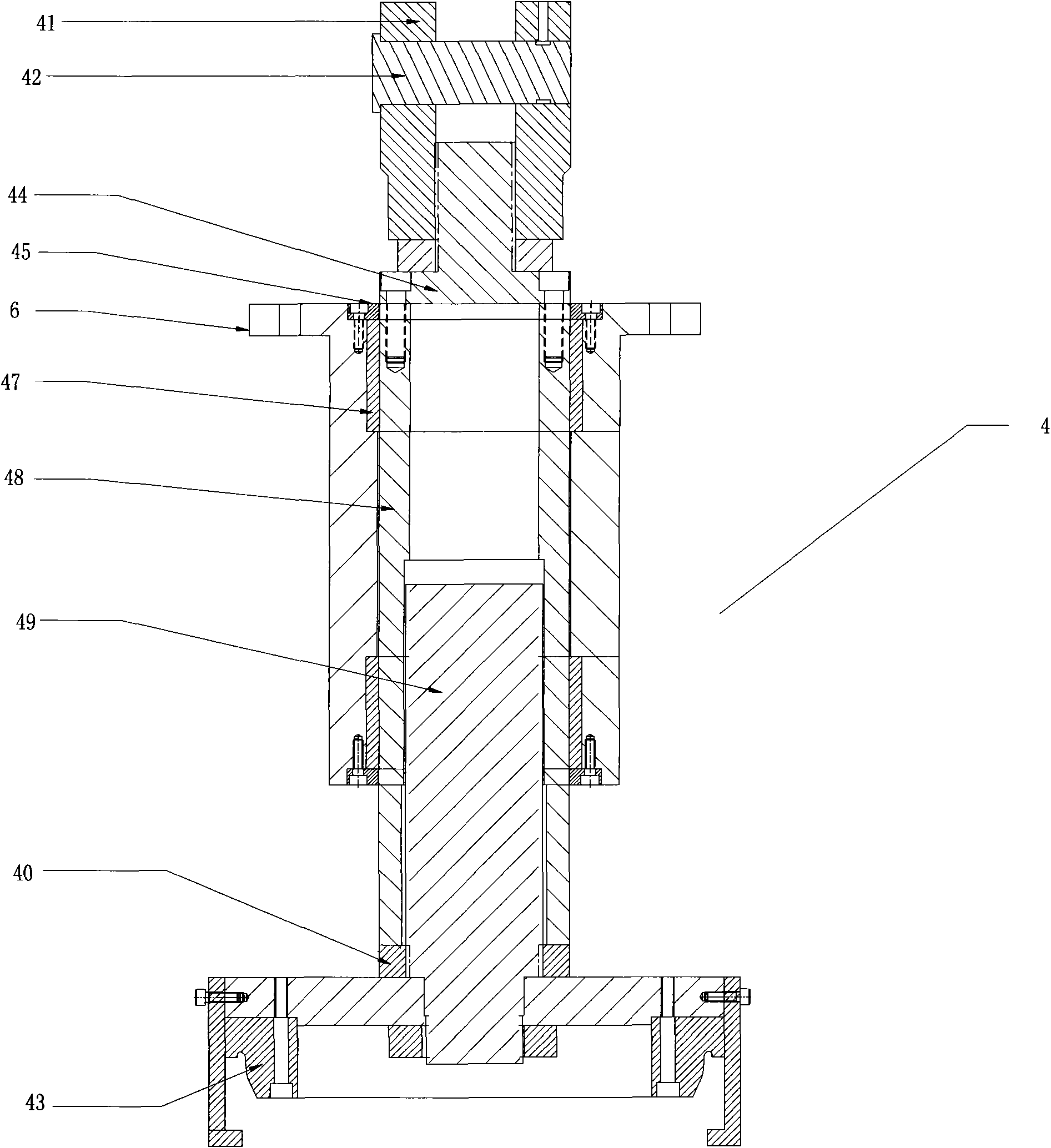

[0015] See Figure 1-3 As shown, the can-making machinery for rolling mouth and body provided by the present invention includes a frame 1, a power unit 2 installed on the top of the frame 1, and the power unit 2 is provided with no less than two eccentric wheels 21, 22, One of the lower ends of the eccentric wheel 21 is equipped with a rib expansion device 3, and the lower end of the other eccentric wheel 22 is equipped with a rolling device 4. The rolling device 4 is provided with an adjustment shaft 41 and a slide shaft 42 that can adjust the height of the rolling device. The height of the crimping device 4 can be adjusted conveniently, so that the crimping cans of different heights can be processed. The frame 1 includes an upper base body 11, a workbench 12, a lower base body 13 and a support rod 14. The frame 1 is spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com