Red bean paste grain concentrated pulp and preparation method thereof

A technology for thick cereal pulp and red bean paste, applied in the field of non-alcoholic beverages, can solve the problems of losing the taste and flavor of red bean paste, poor product quality stability, reducing nutritional value, etc., and achieves strong bean paste flavor, inhibits starch retrogradation, and strong bean paste flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

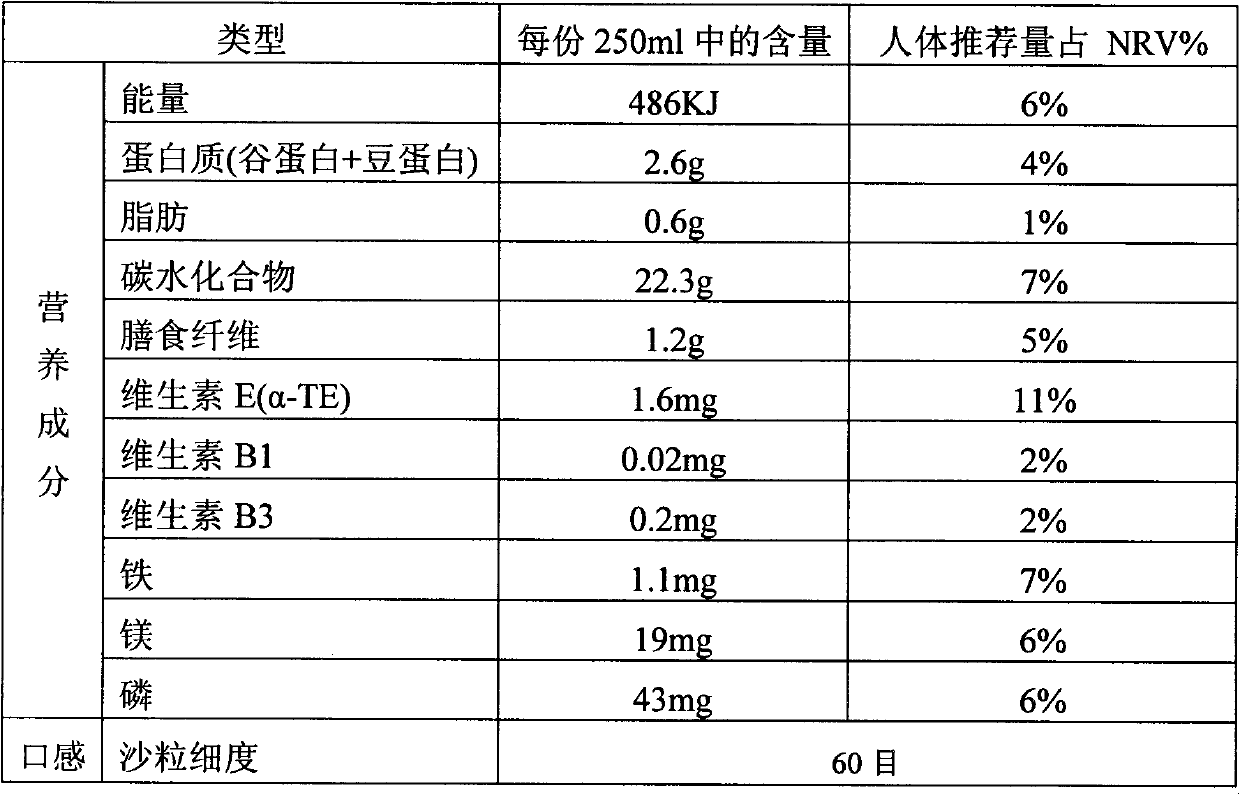

[0049] A non-alcoholic beverage red bean paste grain thick slurry is prepared from the following raw material components by mass percentage:

[0050] Red bean 4.7%, black bean 1.1%, dry cowpea 1.4%, white sugar 7%, non-dairy creamer 0.2%, maltodextrin 2.5%, compound stabilizer 0.25%, and the balance is reverse osmosis pure water; The components are as follows: monoglyceride 80%, xanthan gum 11%, sodium carboxymethyl cellulose 8%, sodium citrate 1%.

[0051] The preparation method is as follows:

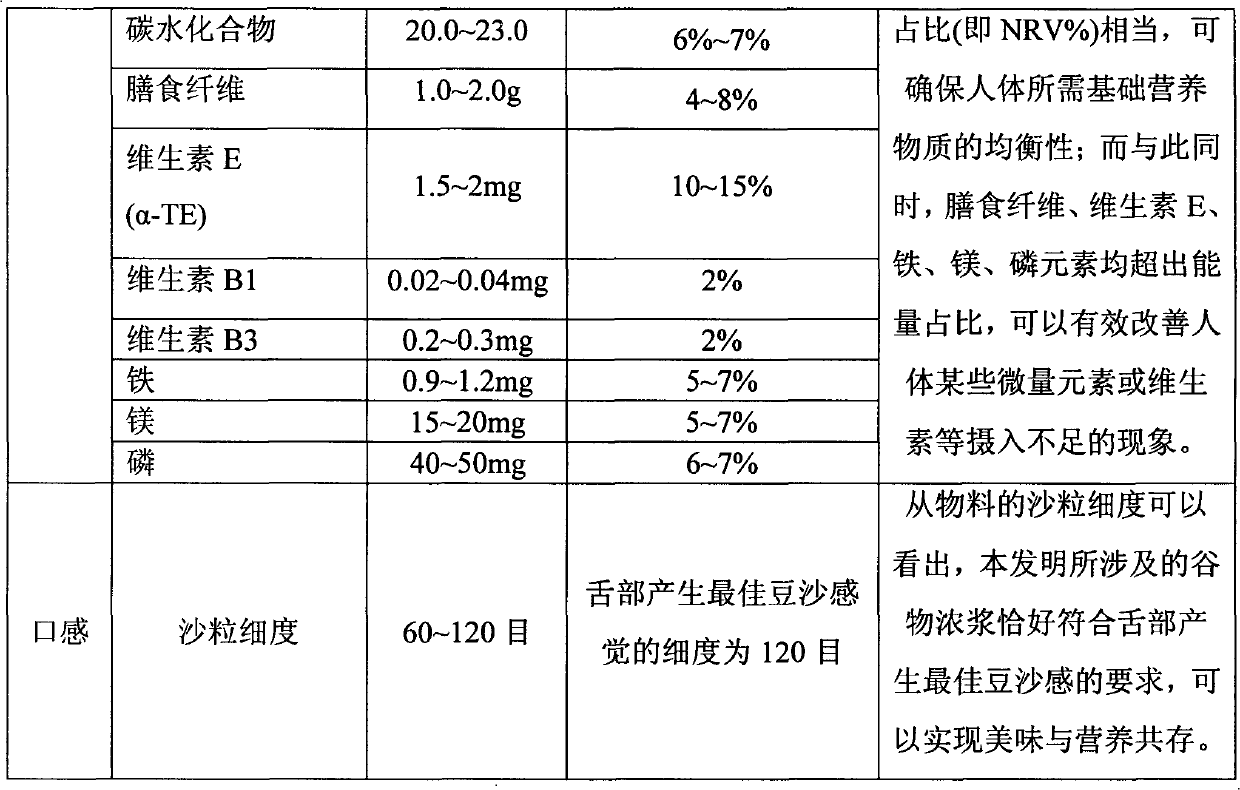

[0052] (1) After mixing the peeled black beans with red beans, dry cowpeas and water, under the condition of a pressure of 0.1Mpa, after cooking for 30 minutes, after grinding and sieving, the grain fineness of 60 meshes is obtained. , the weight percentage of water in the cereal concentrate is 80%;

[0053] (2) After mixing white sugar, maltodextrin, non-dairy creamer and compound stabilizer, add them into water at 80°C to dissolve, and stir for 15 minutes until the mixture is unif...

Embodiment 2

[0063] Embodiment 2: The red bean paste grain thick slurry is obtained by the following raw material components by mass percentage:

[0064] Red bean 3.6%, black bean 1.8%, dry cowpea 1.0%, white granulated sugar 5%, non-dairy creamer 0.8%, maltodextrin 0.5%, compound stabilizer 0.42%, and the balance is purified water. The components of the composite stabilizer are as follows: monoglyceride 77%, xanthan gum 12%, sodium carboxymethyl cellulose 7%, and sodium citrate 4%.

[0065] The preparation method is as described in Example 1, except that:

[0066] In step (1), the pressure is 0.05Mpa, the cooking time is 40 minutes, the grain fineness of the cereal concentrate is 120 mesh, and the weight percent of water in the cereal concentrate is 60%;

[0067] In step a in step (4), the preparation solution is degassed under the condition of -55MPa, and the temperature difference before and after the degassing of the preparation solution is 6°C; in step b, the first high-pressure homo...

Embodiment 3

[0073] The non-alcoholic beverage red bean paste grain thick slurry as described in Example 1 is prepared from the following raw material components by mass percentage:

[0074] Red bean 4.8%, black bean 0.8%, dry cowpea 0.8%, white granulated sugar 7%, non-dairy creamer 0.3%, maltodextrin 1.0%, compound stabilizer 0.4%, and the balance is distilled water. The components of the composite stabilizer are as follows: monoglyceride 70%, xanthan gum 18%, sodium carboxymethyl cellulose 10%, and sodium citrate 2%.

[0075] The preparation method is as described in Example 1, except that:

[0076] In the step (1), the pressure is 0.08Mpa, the cooking time is 30 minutes, the grain fineness of the cereal concentrate is 100 mesh, and the weight percent of water in the cereal concentrate is 65%;

[0077] In step a in step (4), the preparation solution is degassed under the condition of -40MPa, and the temperature difference before and after the degassing of the preparation solution is 4°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com