Optical waveguide, method for manufacturing the optical waveguide, and optical device provided with the optical waveguide

A technology of optical waveguides and optical devices, applied in the directions of light guides, optical components, instruments, etc., can solve the problems of enlarged space, limited dispersion compensation characteristics, difficult miniaturization, etc., and achieve the degradation of S/N ratio reduction and dispersion compensation. Wide range of features and reduced setting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0190]Designed in the wavelength region [1545nm~1555nm], the dispersion amount D=-10ps / nm, the ratio of dispersion slope to dispersion RDS=0.0034nm -1 A dispersion compensation device for compensation of wavelength dispersion. The dispersion compensating device is mainly used for compensating the dispersion not fully compensated by the DCF because the amount of dispersion to be compensated is relatively small.

[0191] Figure 5 is a graph showing the potential distribution of the NPWG of the dispersion compensation device fabricated in this example. The horizontal axis in the figure represents the position normalized with the center wavelength of 1550 nm. Using this potential, we get Figure 6 The group delay characteristics shown and the Figure 7 The reflectance characteristics shown. The spectral data used in the design (designed) and the obtained spectral data (realized) are shown in two figures.

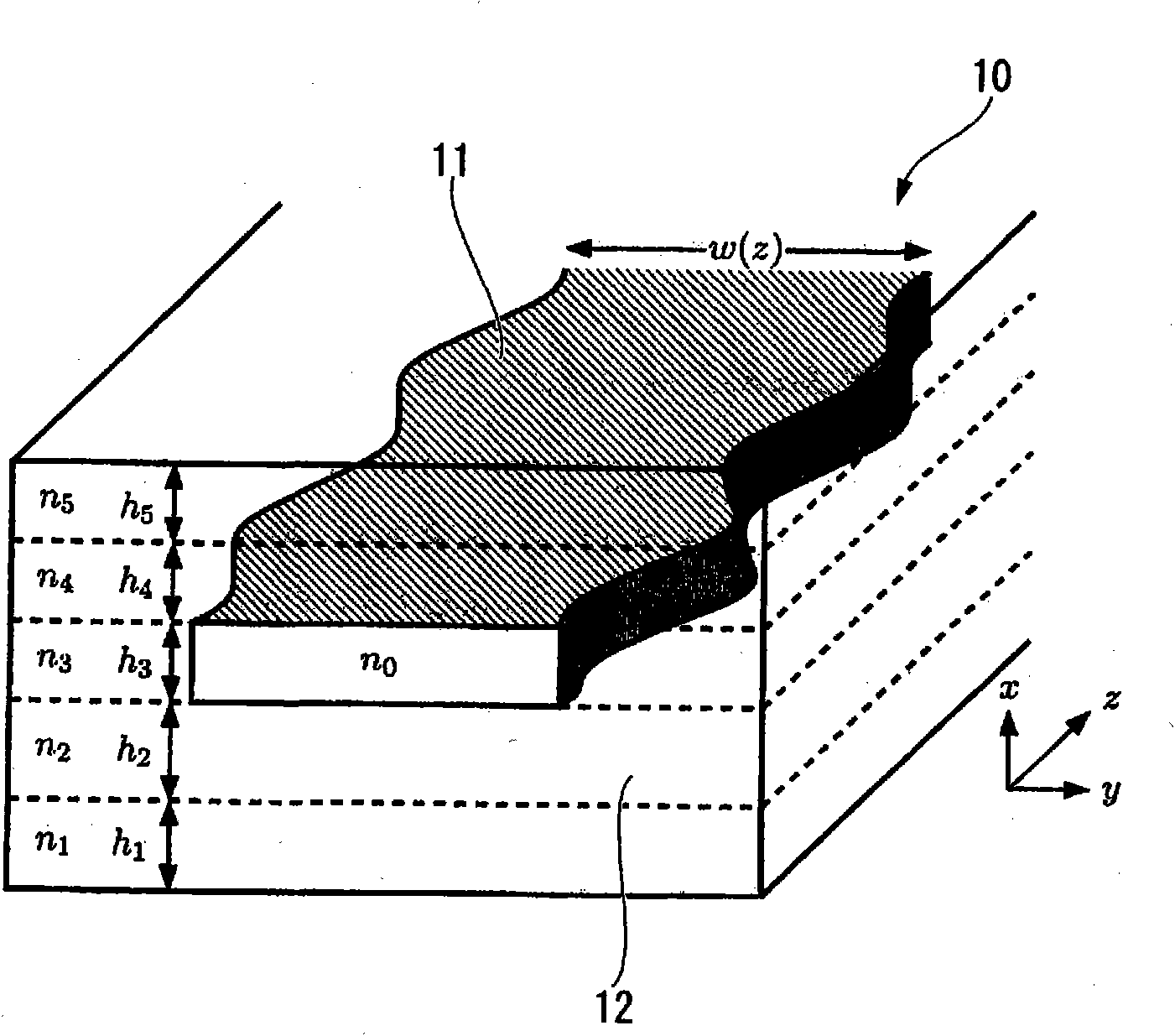

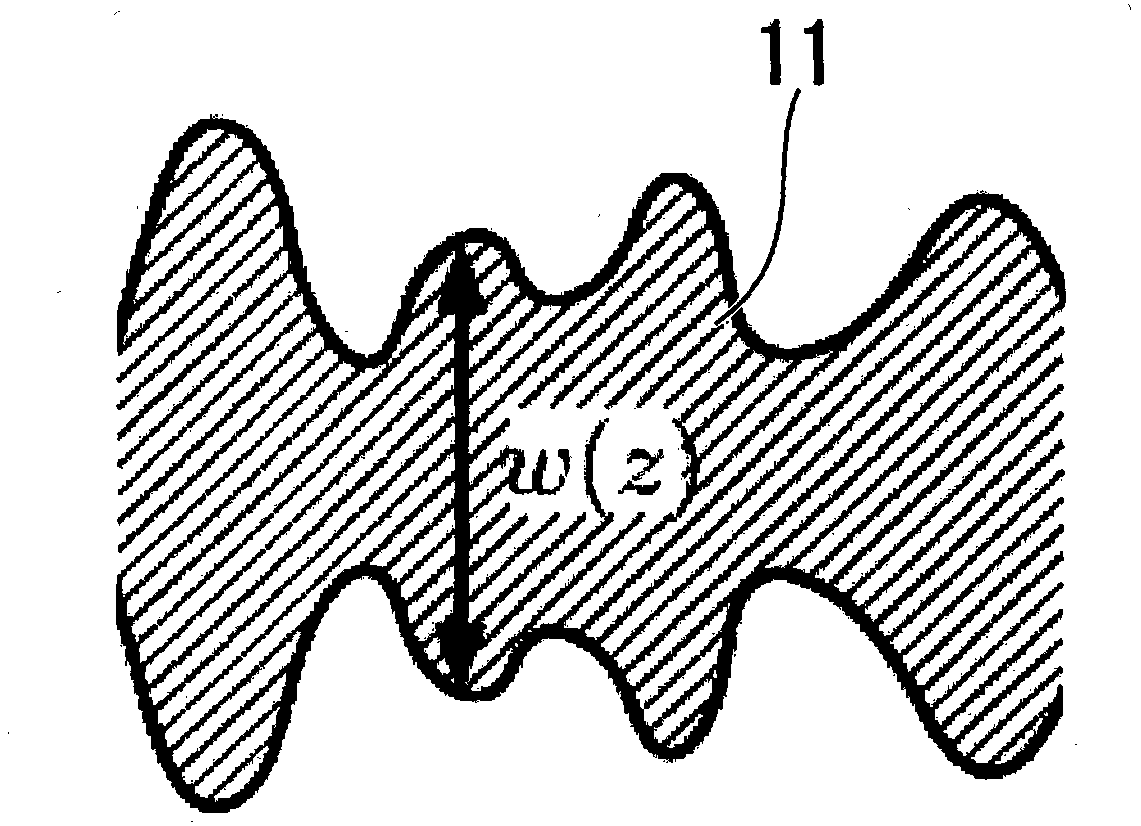

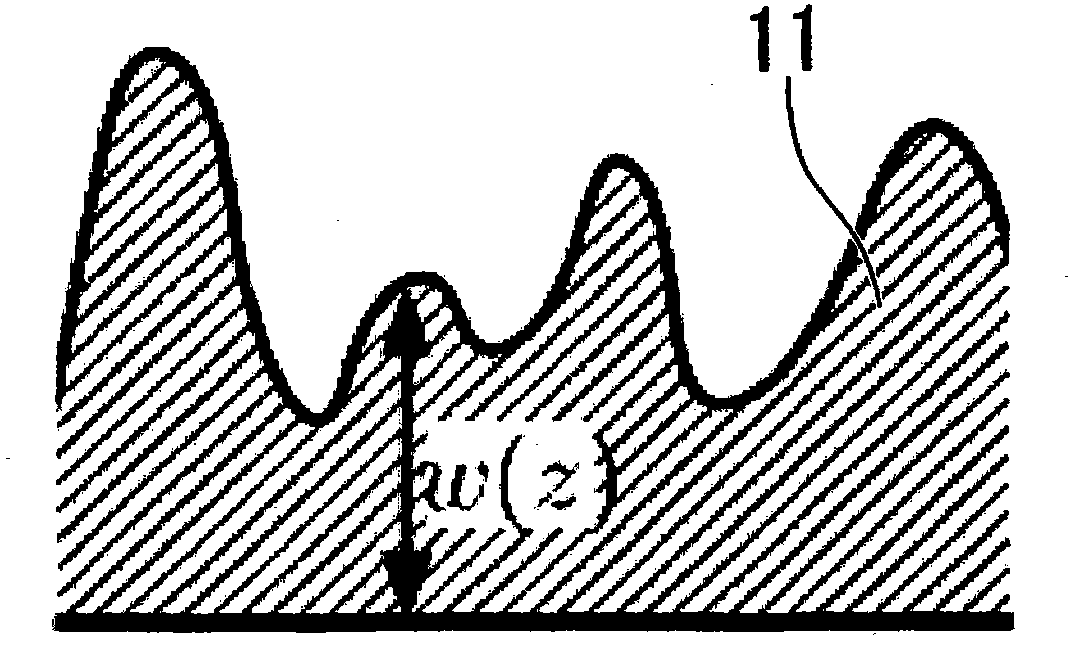

[0192] The NPWG of this embodiment adopts h 3 =6 μm and a relative ...

Embodiment 2

[0197] Designed in the wavelength region [1545nm~1555nm], the dispersion amount D=-50ps / nm, the ratio of dispersion slope to dispersion RDS=0.0034nm -1 A dispersion compensation device for compensation of wavelength dispersion. The dispersion compensating device is also similar to the first embodiment, and is mainly used for compensating the dispersion not fully compensated by the DCF.

[0198] Figure 13 is a graph showing the potential distribution of the NPWG of the dispersion compensation device fabricated in this example. The horizontal axis in the figure represents the position normalized with the center wavelength of 1550 nm. Using this potential, we get Figure 14 The group delay characteristics shown and the Figure 15 The reflectance characteristics shown. The spectral data used in the design (designed) and the obtained spectral data (realized) are shown in two figures.

[0199] The NPWG of this embodiment adopts h 3 =6 μm and a relative refractive index diffe...

Embodiment 3

[0201] Designed in the wavelength region [1545nm~1555nm], the dispersion amount D=-100ps / nm, the ratio of dispersion slope to dispersion RDS=0.0034nm -1 A dispersion compensation device for compensation of wavelength dispersion. The dispersion compensation device is also similar to the above-mentioned embodiments, and is mainly used for compensating the dispersion not fully compensated by the DCF. In this embodiment, it is possible to compensate the wavelength dispersion of a standard single-mode fiber (S-SMF: Standard Single-Fiber) with a length of about 6 km.

[0202] Figure 18 is a graph showing the potential distribution of the NPWG of the dispersion compensation device fabricated in this example. The horizontal axis in the figure represents the position normalized with the center wavelength of 1550 nm. Using this potential, we get Figure 19 The group delay characteristics shown and the Figure 20 The reflectance characteristics shown. The spectral data used in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com