Fluid filter

A technology of liquid filter and filter housing, which is applied in the field of oil filter and lubricating oil for cleaning automobile internal combustion engines, and can solve the problems that liquid filters are difficult to obtain filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

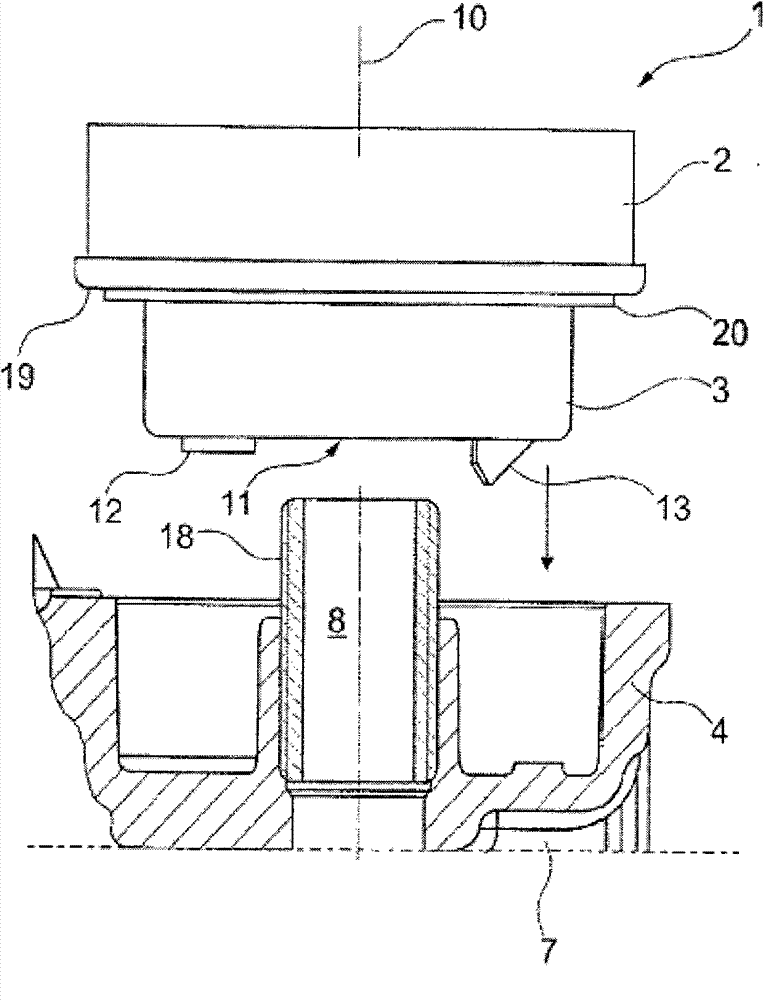

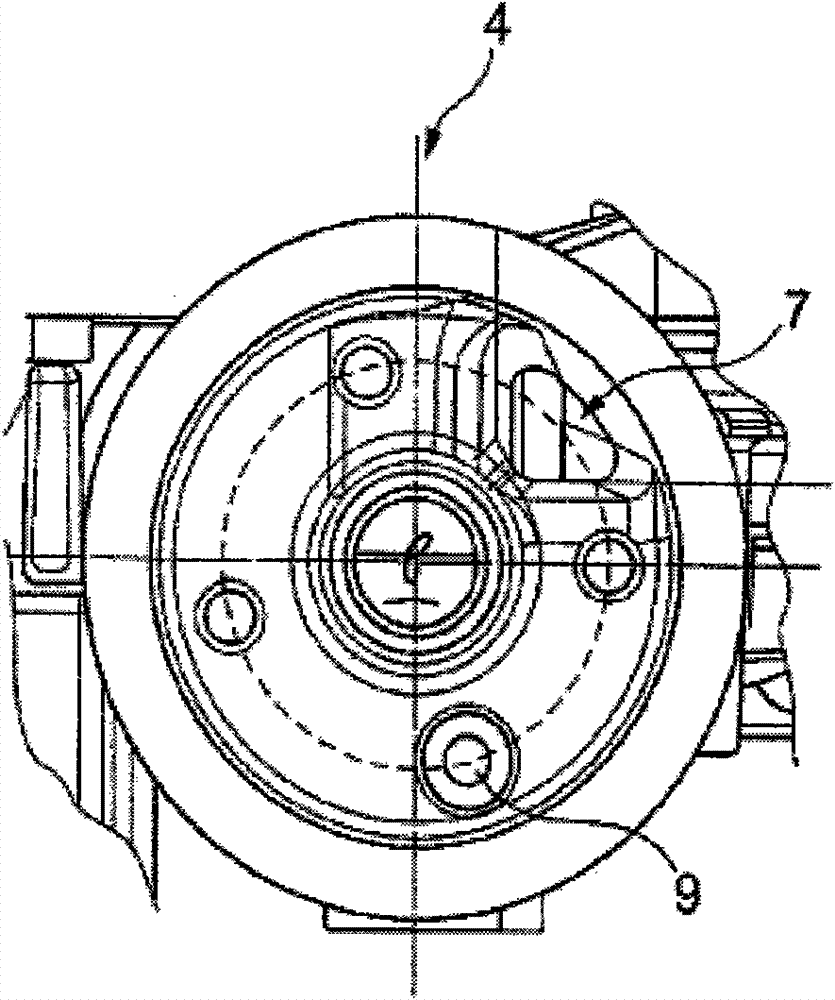

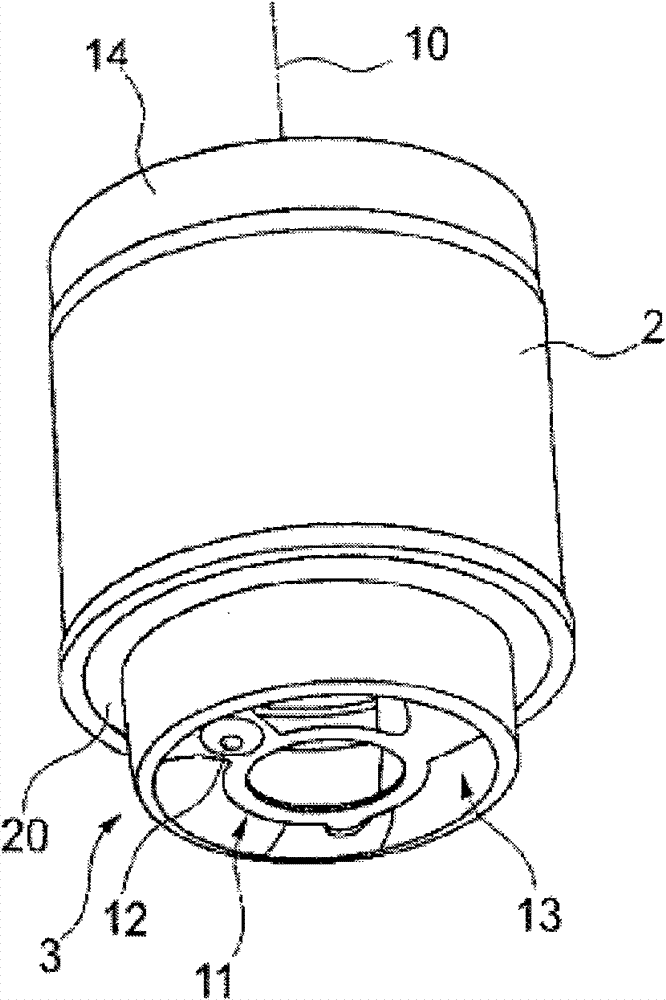

[0018] according to figure 1 , the liquid filter 1 of the present invention comprises a filter housing cover 2, which is only partly shown in the figure, and which has an intermediate block 3 arranged thereunder. The liquid filter 1 also includes a housing 4, figure 1 A sectional view of the housing 4 is shown in , and this housing can be screwed onto the element formed by the filter housing cover 2 and the intermediate block 3 via a threaded connection 18 . The filter housing cover 2 forms the boundary of the housing space 5 for the annular filter element 6, which in Figure 4 shown in . figure 1 Also shown is an intermediate block 3 placed between the filter housing cover 2 and the housing 4, wherein in the housing space 5, as shown, for example, in Figure 4 , the annular filter element 6 is placed in a vertical position.

[0019] In order to ensure the supply and discharge of filtered liquid to and from the liquid filter 1 at least one inlet channel 7 and one outlet ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com