Solar vacuum tube type separated liquid circulation generator

A vacuum tube type, liquid circulation technology, applied in the direction of solar thermal power generation, mechanical power generated by solar energy, machine/engine, etc., to achieve high reliability and realize the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

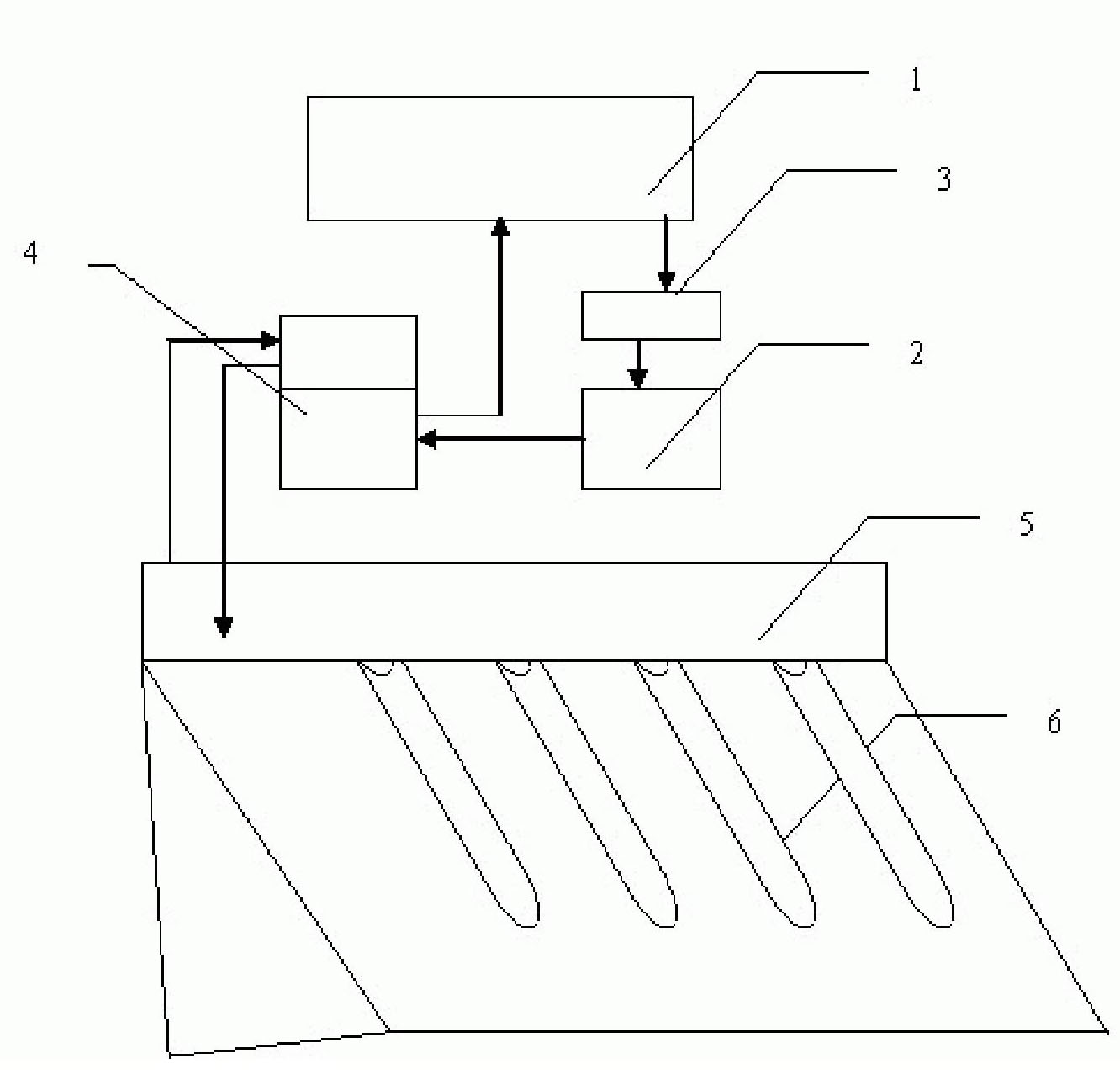

[0043] Embodiment 1. Solar vacuum heat collecting tube liquid cycle power generation system

[0044] Such as figure 1 As shown, a solar vacuum tube with a single opening is used as the collection system, and its thermal energy is used to lift the liquid to complete the power generation of the liquid cycle. Among them, the heat collecting tube of the solar vacuum machine is used as 6 parts of solar energy collection, and a liquid lifting device 4 is used to lift the liquid in the liquid storage box 2, and the liquid is lifted to the working box 1 and then circulated to generate electricity again.

Embodiment 2

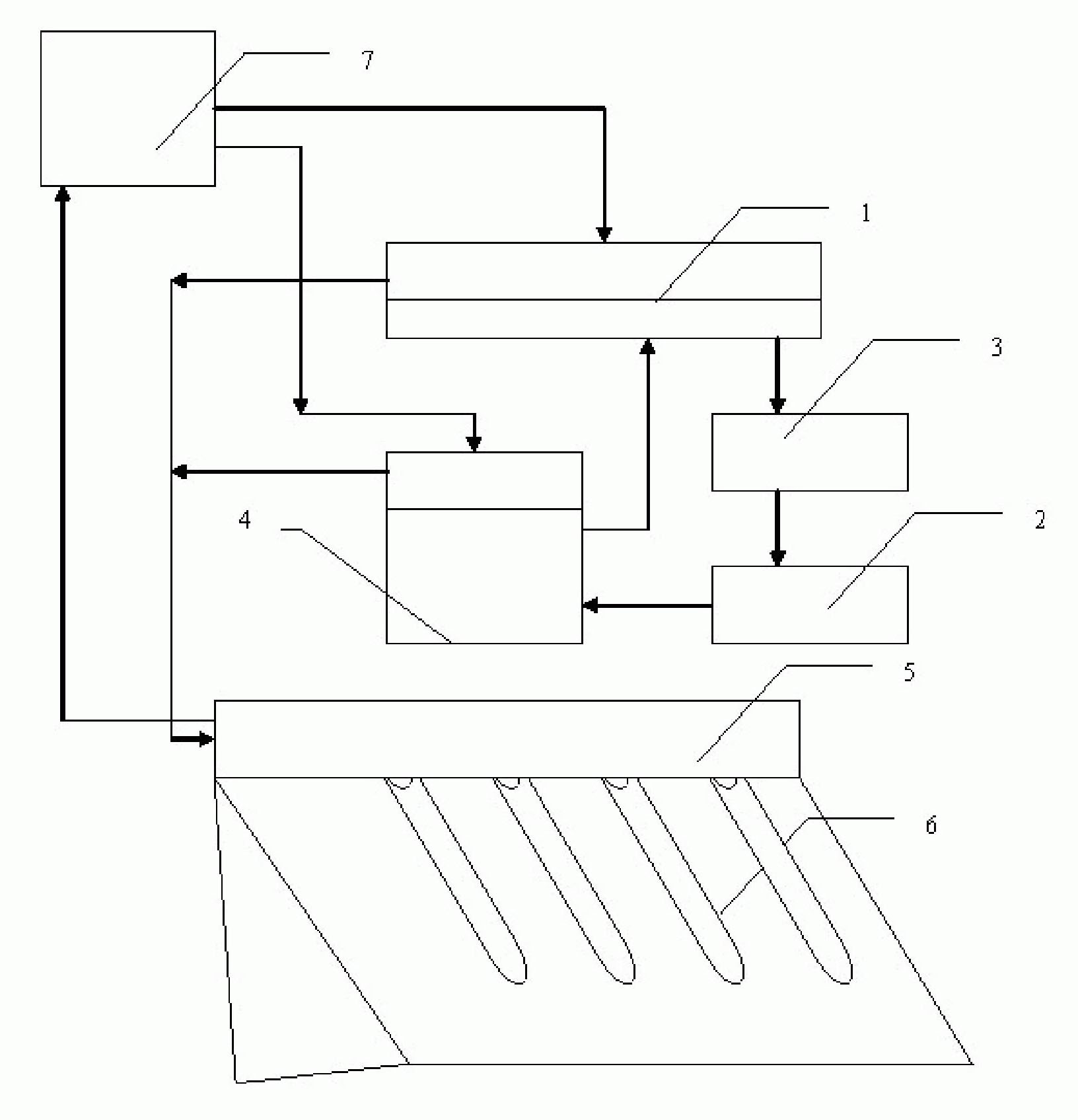

[0045] Embodiment 2. Heat pipe type solar vacuum heat collection tube liquid circulation power generation system

[0046] Such as figure 2As shown, the heat energy collected by the solar energy is used for lifting the liquid and pressurizing the working box and the heat storage box. Among them, the heat pipe type solar energy collection system 1 is adopted, and R245fa or R21 is used as the low-temperature working medium. The piston cylinder structure is adopted in the working box 1 and the liquid lifting device 4, and the gas in the low-temperature working medium box 7 is directly connected with the working box and the liquid. The hoisting device 4 is connected to form a loop, and the solar energy collection system is connected to the low-temperature working medium box to form a loop. The liquid circulates under the heat energy collected by the solar energy collection system and provides pressurization to the working box 1 to achieve high efficiency. generate electricity.

Embodiment 3

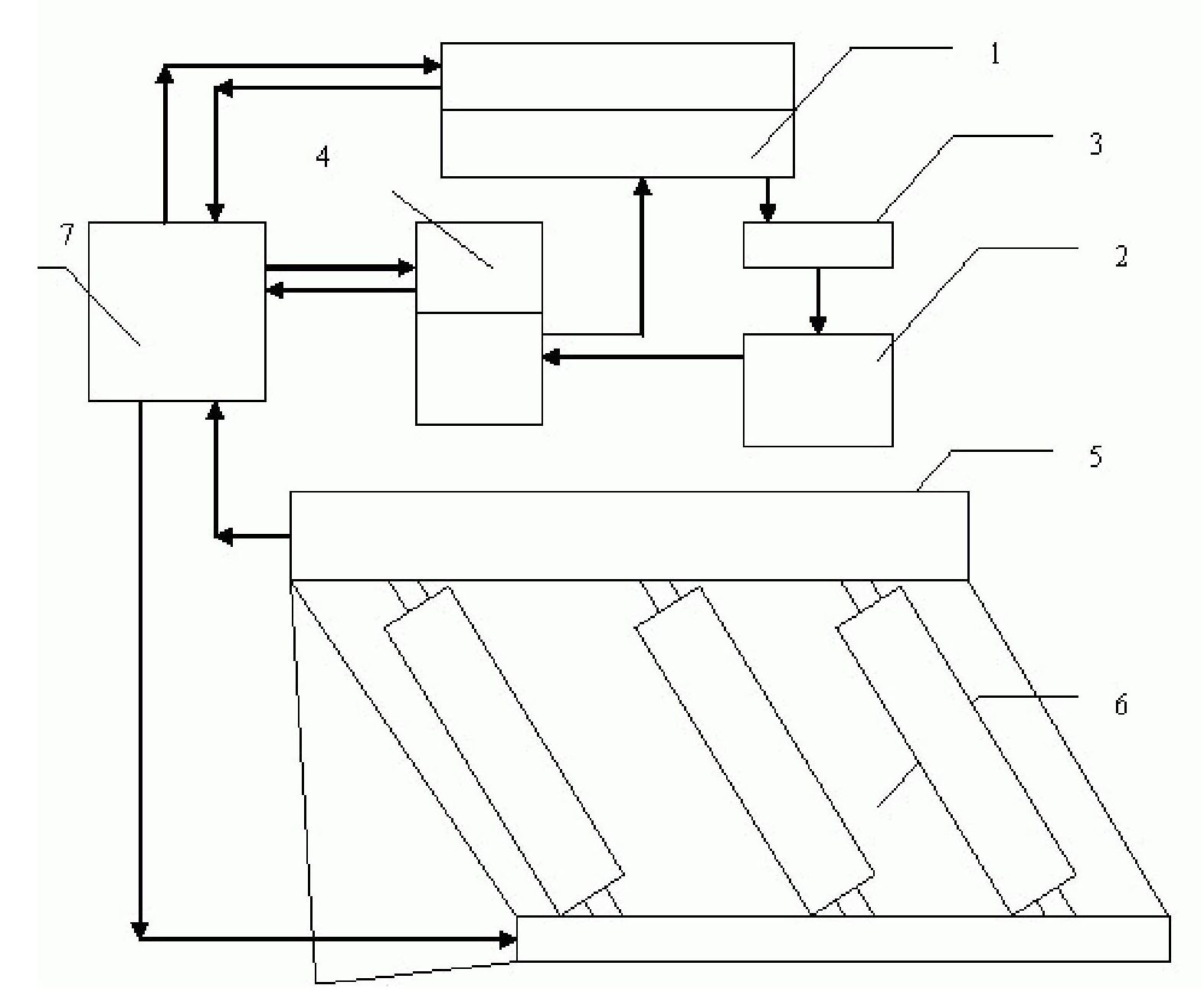

[0047] Embodiment 3. Two-way tube solar vacuum heat collection tube liquid cycle power generation system

[0048] Such as image 3 As shown, in this embodiment, the solar double-way tube is used as the collection part, and the vaporized low-temperature working medium directly enters the low-temperature working box 7, and its condensed liquid enters the vacuum tube from the bottom of the solar double-way tube to realize the The heating of the low-temperature working medium, the heated low-temperature working medium directly lifts the liquid and completes the pressurization of the working box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com