Microphone calibrator and calibration method thereof

A technology for calibrating devices and microphones, applied to electrical components and other directions, can solve problems such as time-consuming and the inability of calibration devices to provide microphone phase calibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

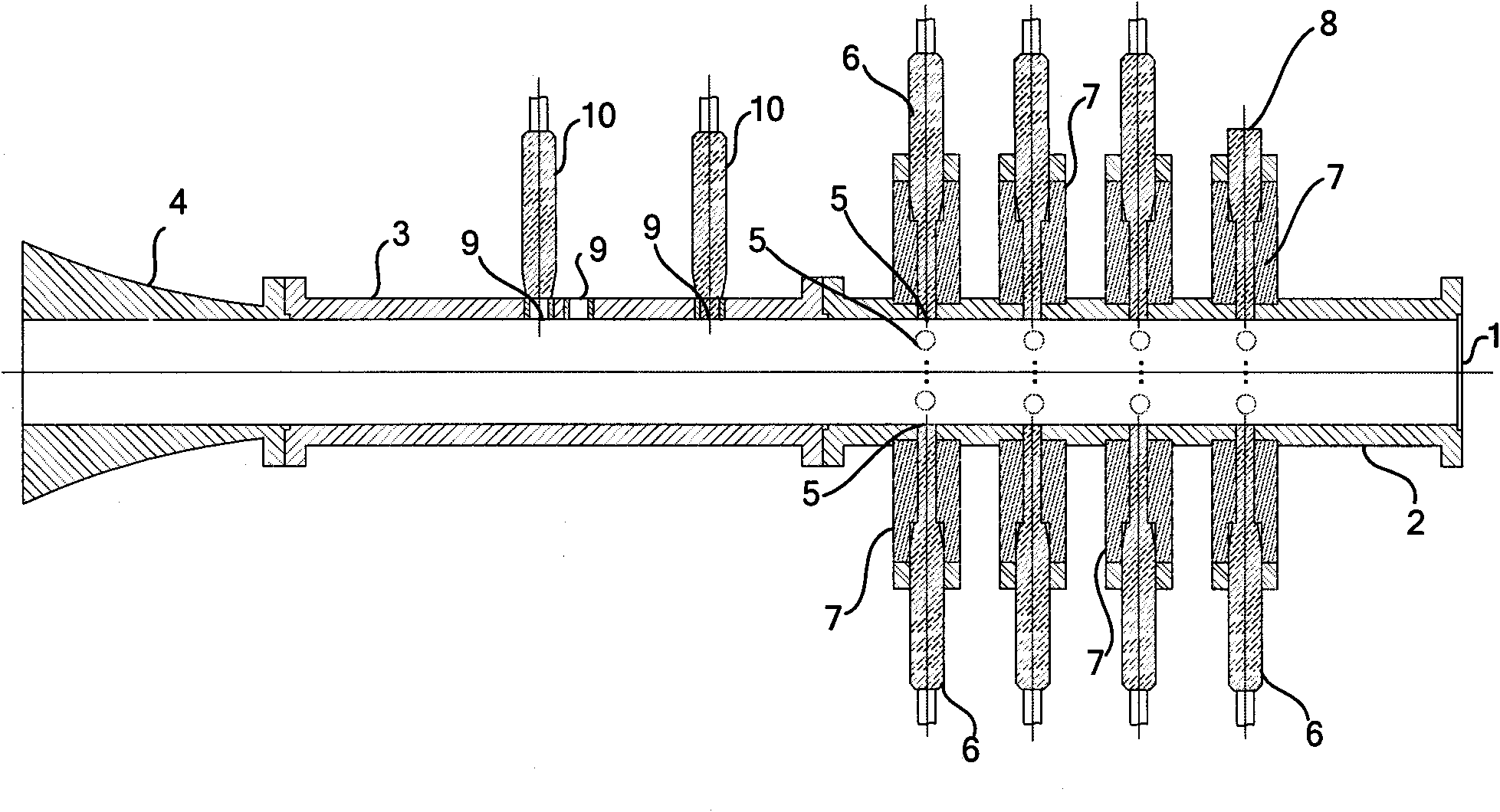

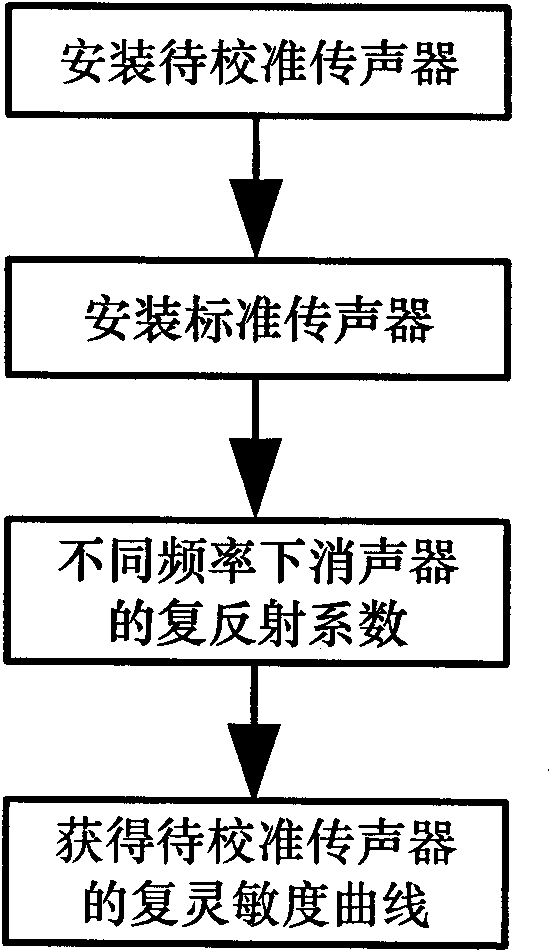

[0066] The present invention will be further described below in conjunction with the accompanying drawings.

[0067] A kind of microphone calibration device of the present invention, comprises sound source 1, microphone installation section 2 to be calibrated, standard microphone installation section 3 and muffler 4,, muffler 4, microphone installation section 2 to be calibrated, standard microphone installation section 3 and sound source 1 by The flange connection is used from front to back in turn, and the internal design has a spigot for positioning, which enhances the sealing between the sound source 1, the microphone installation section 2 to be calibrated, the standard microphone installation section 3, and the muffler 4. An integral straight tube is formed inside the installation section 2 of the microphone to be calibrated, the installation section 3 of the standard microphone and the installation section of the muffler 4 .

[0068] Wherein, the sound source 1 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com