Manufacturing method of carbon nanotube gas sensor based on corona discharge

A gas-sensing sensor and carbon nanotube technology, applied in the field of gas-sensing sensors, can solve the problems of complex structure and process of carbon nanotube sensors, and achieve the effects of good detection repeatability, high sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for manufacturing a gas sensor based on carbon nanotube corona discharge, characterized in that the following steps are adopted:

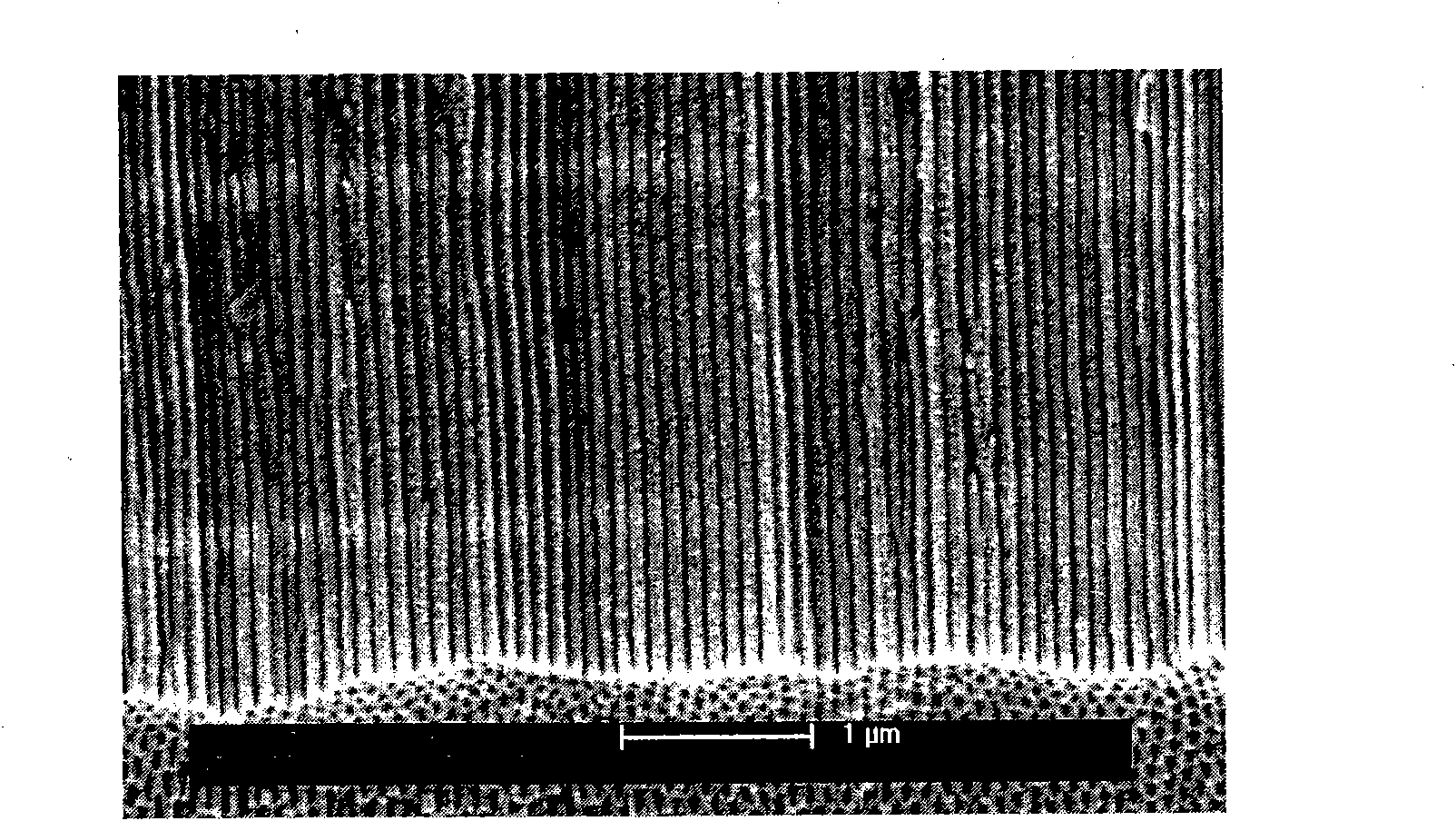

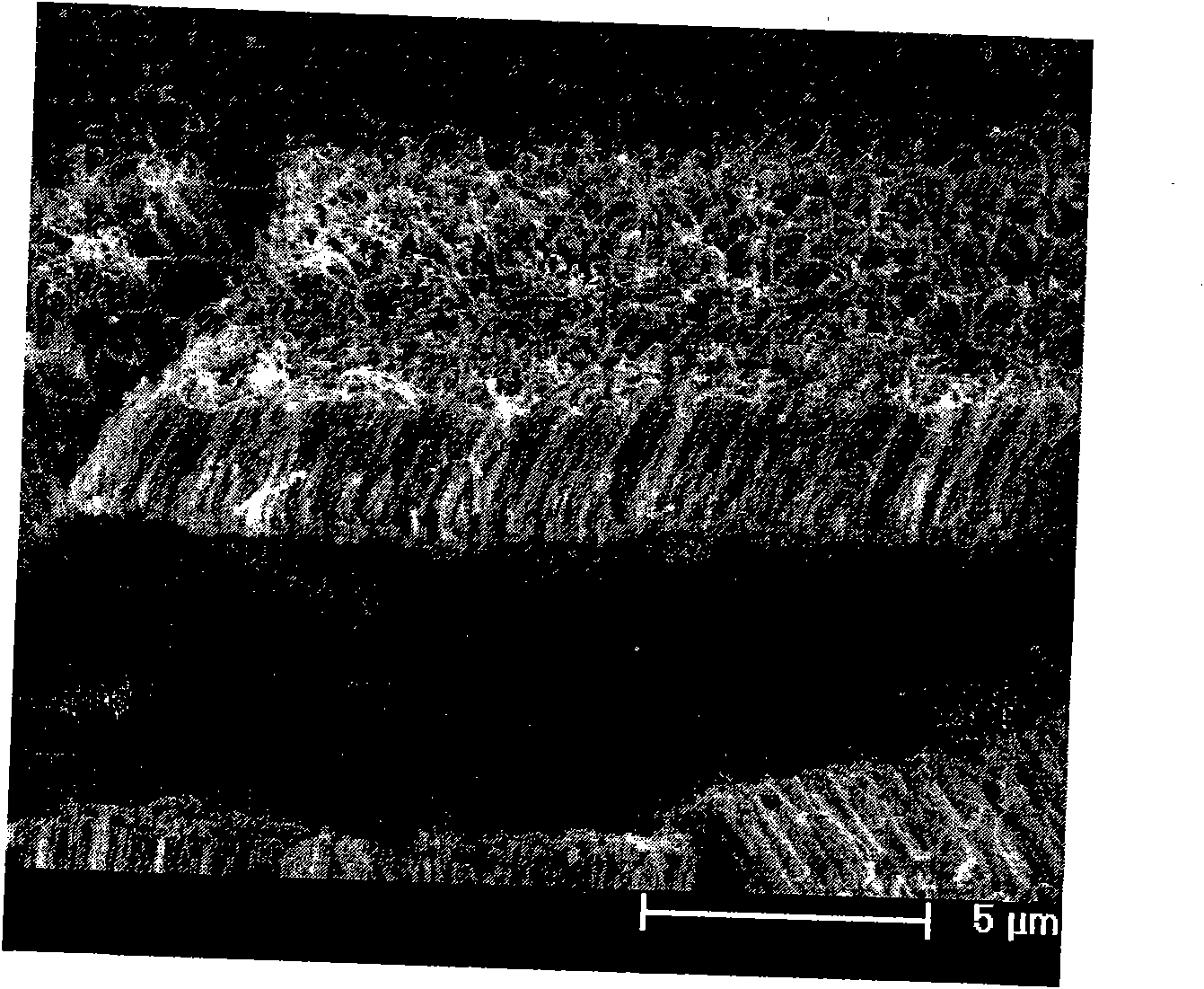

[0023] A) Cut the annealed high-purity aluminum foil into a suitable size, place it in a 0.3M oxalic acid solution after electrochemical polishing and cleaning, put it in an ice bath, and anodize at a voltage of 40V for 1h; then put the oxidized template in phosphoric acid and chromic acid Soak in the mixed solution for 1 hour, and then repeat the same oxidation steps above; finally, carry out step-down step-down treatment, from 40V to 2V every 10min time interval, until the voltage drops to 10V, the required AAO template can be obtained, and the mixed solution The molar ratio of phosphoric acid and chromic acid in the medium is 3:1, the average diameter of the nanopores of the template is 50nm, and the nanopore density is 10 6 piece / mm 2 , the nanopore length is 10 μm, the FSEM image of AAO template is as follows figure 1 shown; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com