Intensive air-handling unit

An air handling unit, intensive technology, applied in the direction of air conditioning system, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of work and life impact, noise pollution, etc., to achieve a reasonable and compact structure of the unit, saving operation The effect of saving the cost and saving the area of the computer room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

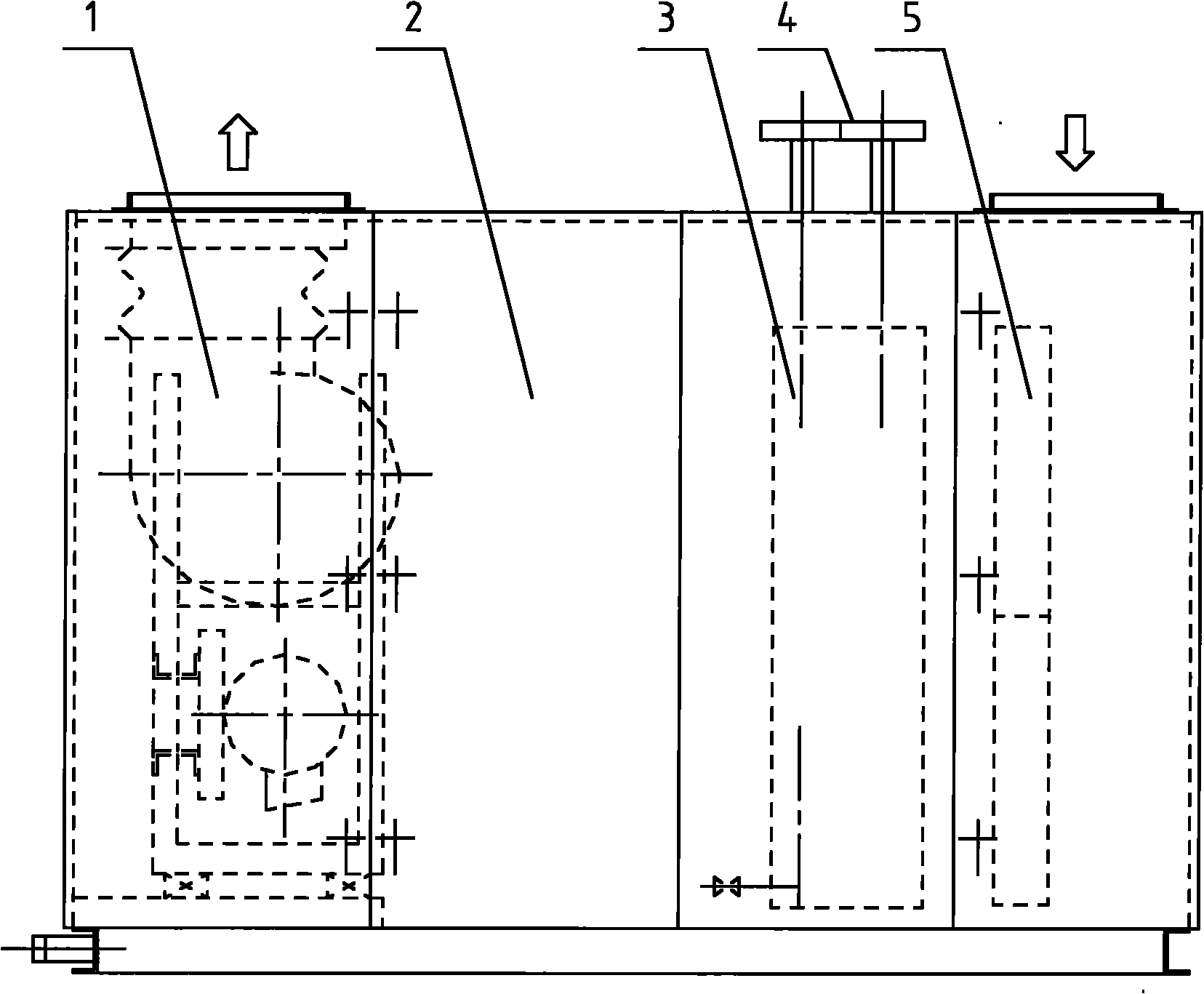

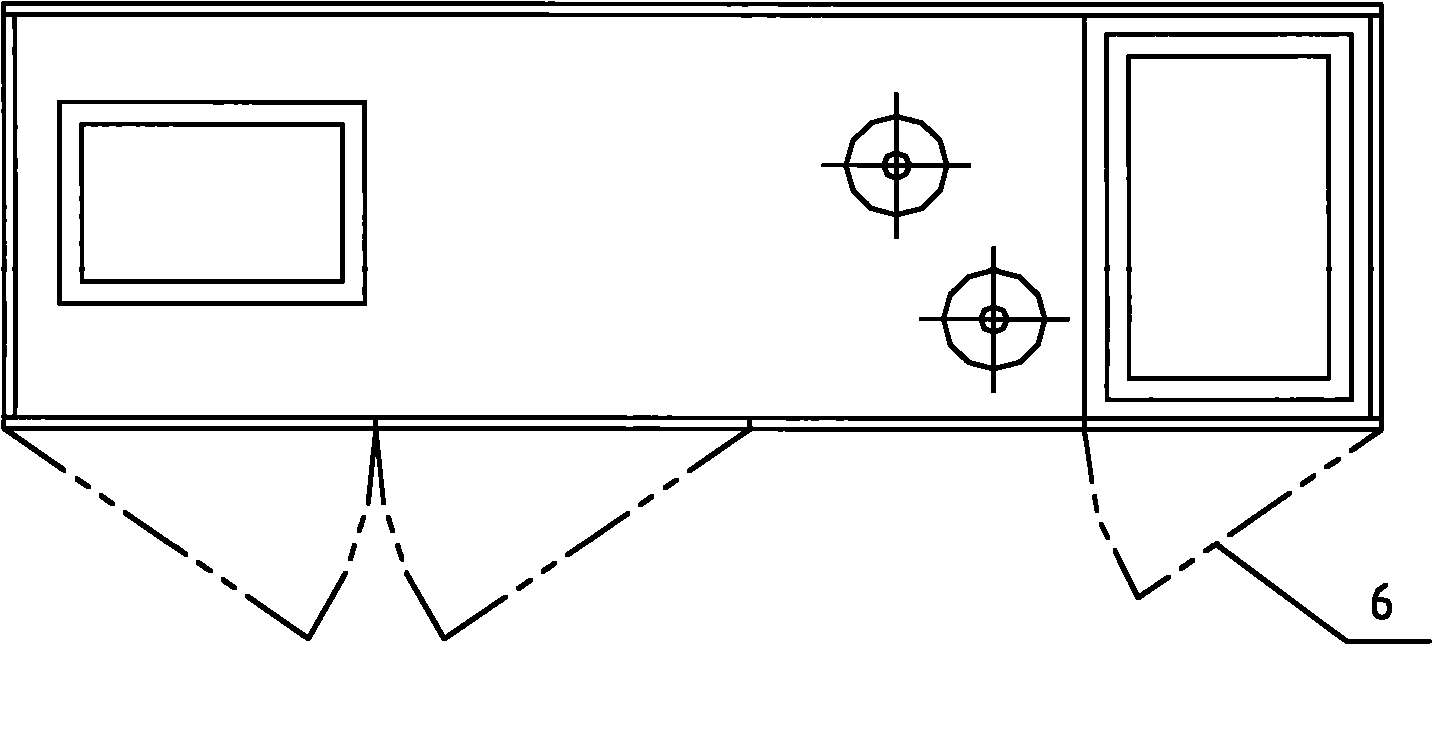

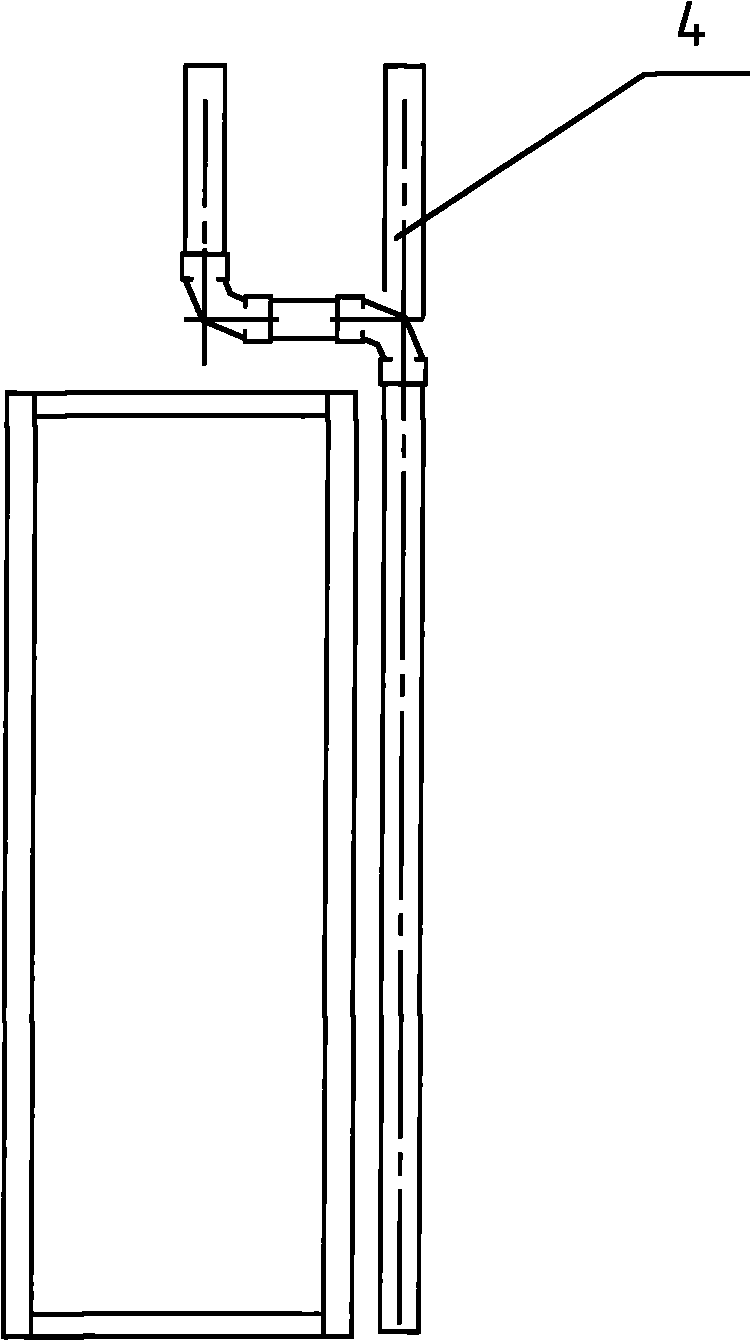

[0017] Such as figure 1 , 2 , 3, 4, and 5, the intensive air handling unit includes a box body 2, a fan 1, a heat exchanger 3 and a filter screen 5 are installed in the box body 2, and the box body 2 is a vertical flat type The box body, the fan 1 is a vertical fan with a motor under it, the heat exchanger 3 is a vertical flat tube heat exchanger, and the outlet of the heat exchanger 3 is connected with a heat exchanger connecting pipe 4 . This structure makes the unit structure more reasonable and compact, occupies a small area, is convenient to place, and realizes wall-mounted placement, which saves the user's machine room area to the minimum. The small air volume unit does not even need to set up a special machine room, and uses a flat tube heat exchanger. 3. The power consumption of the fan 1 is reduced, the operating cost is saved, and the operating noise of the unit is reduced. In addition, due to the increase of the operating wind speed of the unit and the reasonable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com