Lamination combining type rectangular oil cylinder

A combined type and oil cylinder technology, which is applied in the direction of cylinders, engine components, mechanical equipment, etc., to achieve the effects of enhanced rigidity, strong resistance to deformation under force, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The laminated combined rectangular oil cylinder will be described in detail below in conjunction with the embodiments.

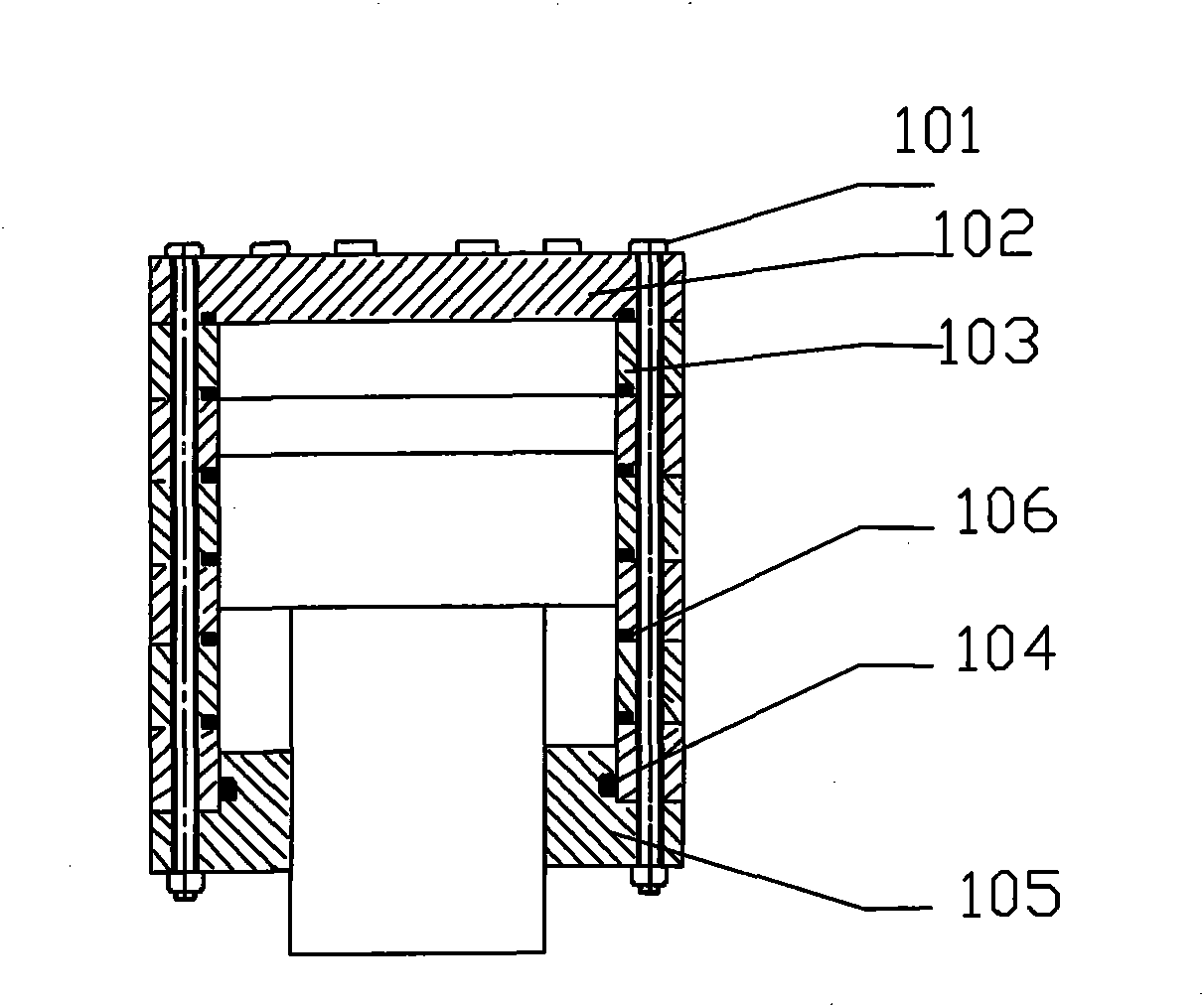

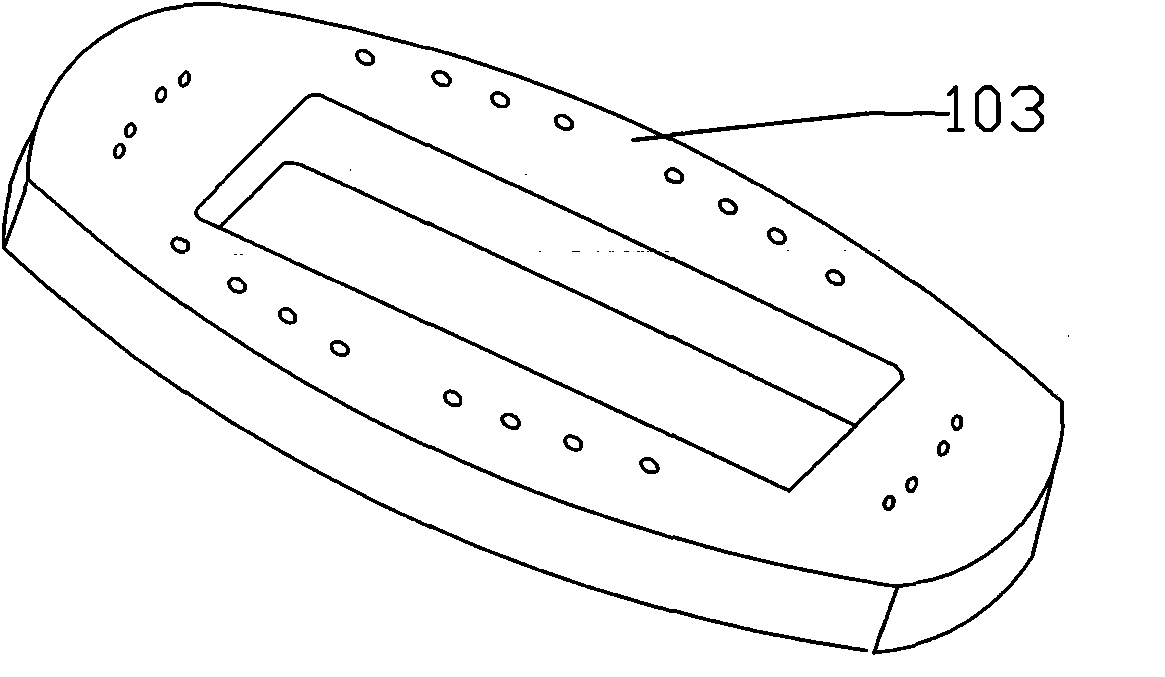

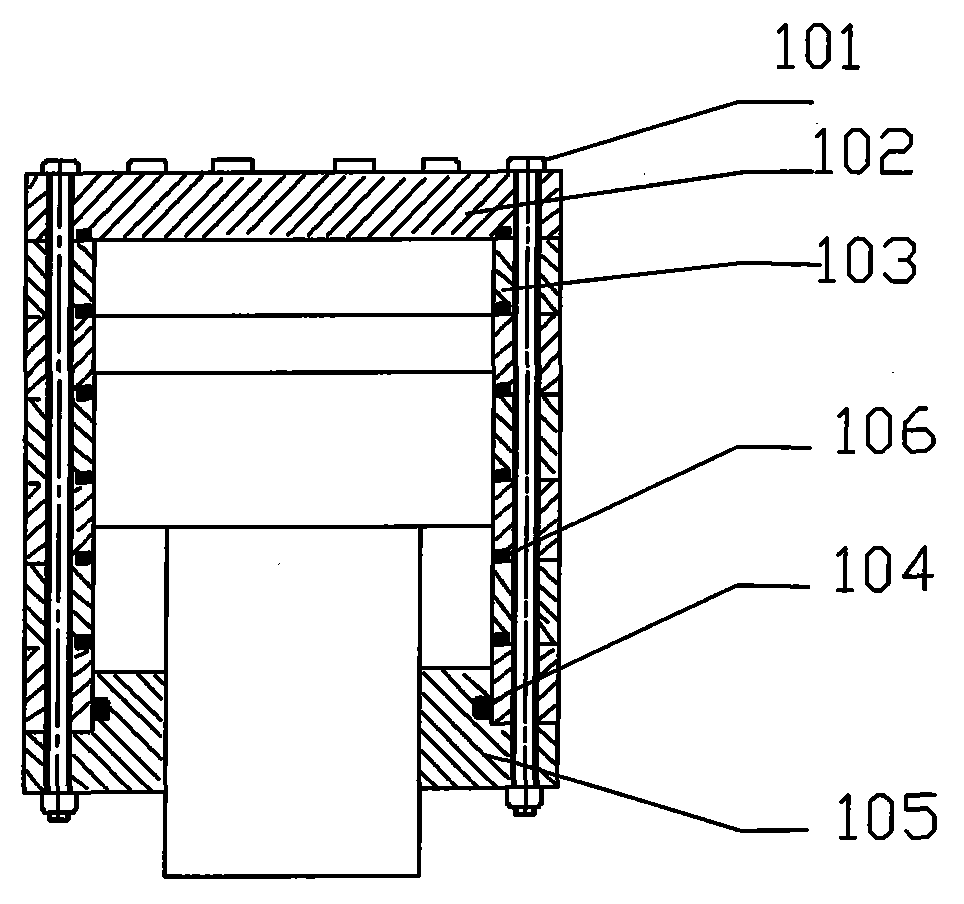

[0014] like figure 1 and figure 2 As shown, the shape of the oil cylinder body is rectangular, and the oil cylinder body is composed of a plurality of cylinder parts, and the cylinder parts are several cylinder structure layers 103 in the transverse direction of the oil cylinder body, each The cylinder structure layer 103 is processed separately, and the thickness of each cylinder structure layer is between 50mm and 250mm. Bolt holes and pin holes are opened on each layer of cylinder body. The cover 102 and the lower end cover 105 are connected with the cylinder structure layers 103 of each layer, and the cylinder structure layers are positioned with pins to form an integral sealed oil cylinder body.

[0015] In order to make the stress distribution everywhere on the cylinder wall of the oil cylinder block relatively uniform, the outer diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com