Production method and device of metallic binderless wire drawing film

A technology of metal texture and production method, applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problem of composite membrane materials losing the market, and achieve the effect of ensuring environmental protection and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

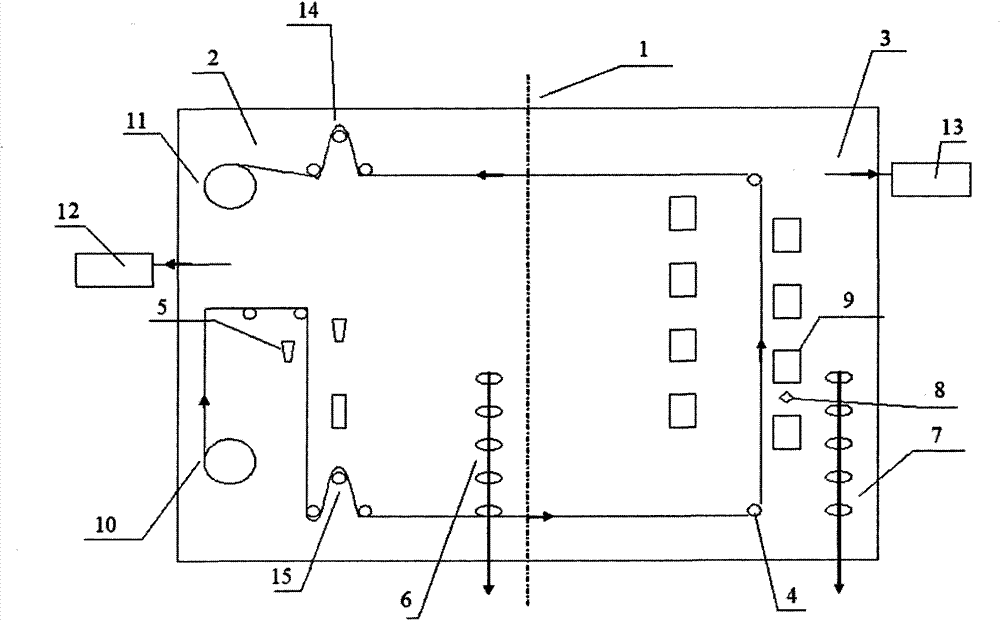

Method used

Image

Examples

Embodiment 1

[0019] The glue-free drawing film is produced according to the following steps: first, draw or print patterns on the substrate; secondly, the drawn substrate is in the discharge chamber, and one side is treated by the ion source under vacuum; finally, enter the sputtering chamber, According to specific requirements, use sputtering target and reaction gas to directly sputter the metal layer on the substrate; among them, the substrate is PC film with a thickness of 0.05mm and a width of 500mm; among them, the ion source is a high-frequency ion source with a power of 2KW and a current of 1A , voltage 220V, argon flow rate 100sccm, argon pressure 0.1mpa; vacuum pressure 1*10 -2 Pa, speed 0.5m / min; Among them, the power of cryogenic trapping is 5kw, the temperature is -100°C, and the trap area is 1 square meter; Among them, the sputtering target is a Ti target, and the sputtering vacuum pressure is 1*10 -2 Pa, the flow rate of argon gas is 100 sccm, the flow rate of nitrogen gas is...

Embodiment 2

[0021] The glue-free drawing film is produced according to the following steps: first, draw or print patterns on the substrate; secondly, the drawn substrate is in the discharge chamber, and one side is treated by the ion source under vacuum; finally, enter the sputtering chamber, According to specific requirements, use sputtering target and reaction gas to directly sputter the metal layer on the substrate; among them, the substrate is a PET film with a thickness of 0.275mm and a width of 1350mm; among them, the ion source is an arc discharge ion source with a power of 6KW and a current of 5.5 A, voltage 1110V, inert gas flow rate 300sccm, pressure 0.55mpa; vacuum pressure 9*10 -2 Pa, speed 2.75m / min; Among them, the power of cryogenic trapping is 27.5kw, the temperature is -125°C, and the trap area is 3 square meters; Among them, the sputtering target is a graphite target, and the sputtering vacuum pressure is 9*10 -2 Pa, the flow rate of argon gas is 300 sccm, the flow rate ...

Embodiment 3

[0023] The glue-free drawing film is produced according to the following steps: first, draw or print patterns on the substrate; secondly, the drawn substrate is in the discharge chamber, and one side is treated by the ion source under vacuum; finally, enter the sputtering chamber, According to specific requirements, use sputtering target and reaction gas to directly sputter the metal layer on the substrate; among them, the substrate is a film with a thickness of 0.5mm and a width of 2200mm; among them, the ion source is a sputtering negative ion source with a power of 10KW and a current of 10A , voltage 2000V, argon flow rate 500sccm, argon pressure 1mpa; vacuum pressure: 9*10 -3 Pa, speed 5m / min; Among them, the power of cryogenic trapping is 50kw, the temperature is -150°C, and the trap area is 5 square meters; Among them, the sputtering target is a Ti target, and the sputtering vacuum pressure is 9*10 -3 Pa, the flow rate of argon gas is 500 sccm, the flow rate of nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com