Extraction multi-chamber mixer used in antibiotic production

A technology of antibiotics and mixers, which is applied in the direction of fluid mixers, mixers, liquid solution solvent extraction, etc., can solve the problems of insufficient fluid mixing, slow mixing speed, and low mixing efficiency, so as to improve the mixing effect and facilitate disassembly , the effect of increasing the turbulence velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

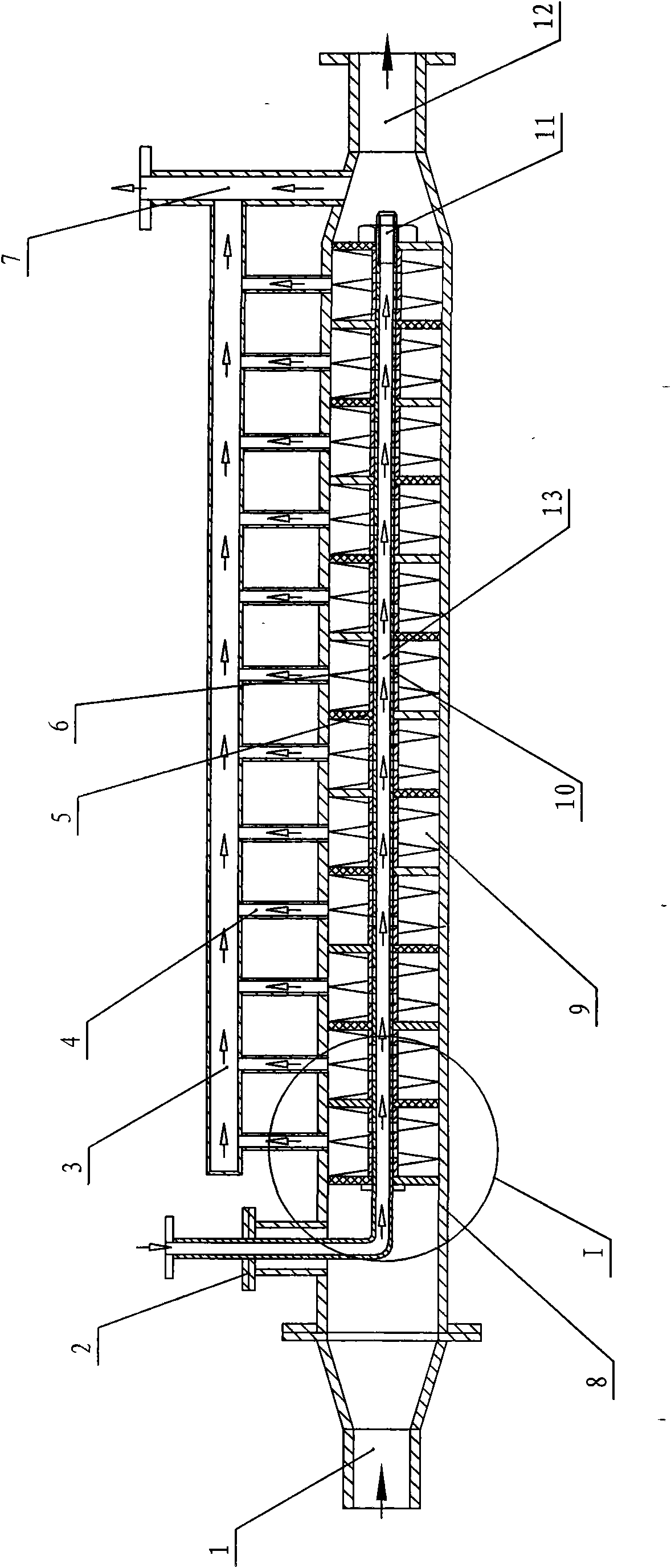

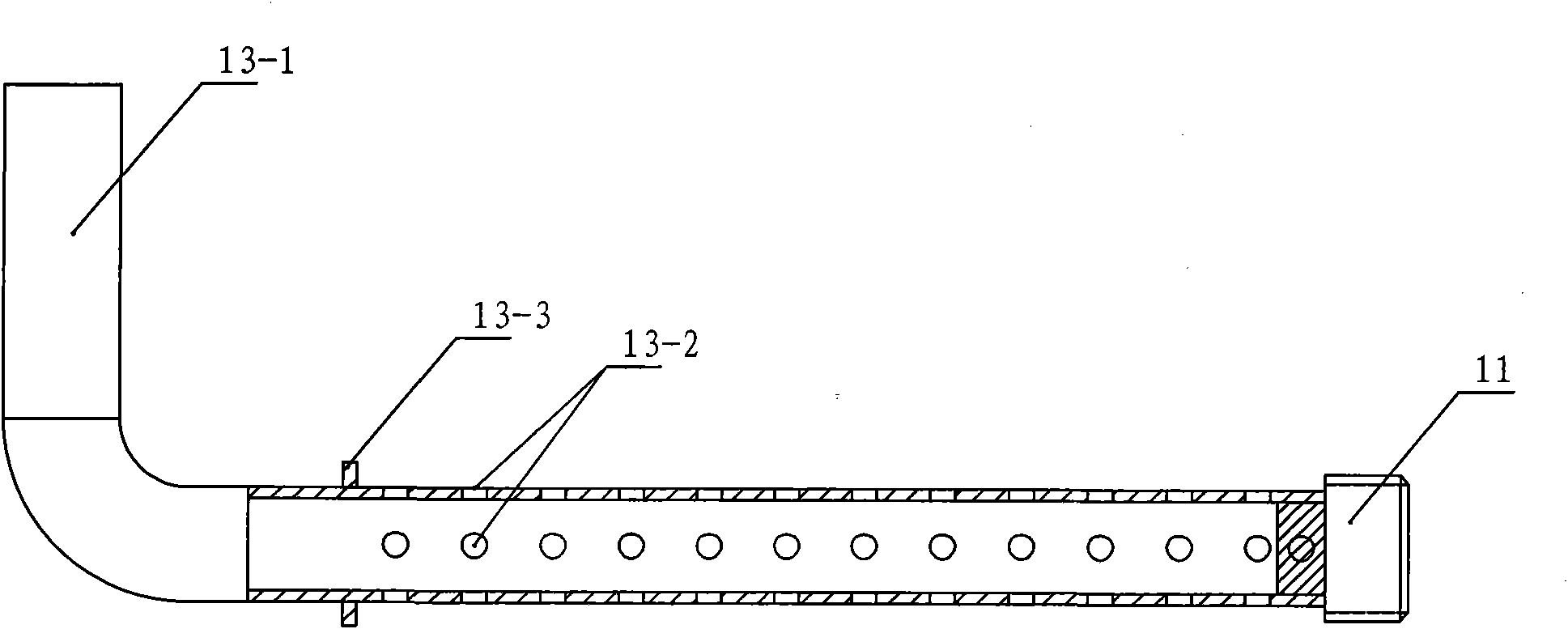

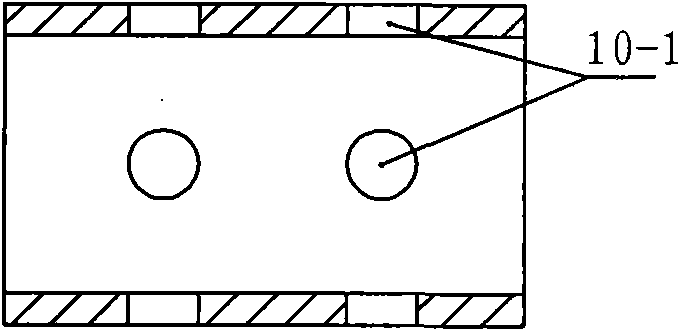

[0030] Example: see Figure 1-Figure 8 , an extraction multi-chamber mixer used in the production of antibiotics in the figure, contains a cylindrical shell, and the two ends of the shell are provided with a feed pipe and a discharge pipe, and a certain number of partitions are arranged in the shell to The interior of the shell is divided into multiple mixing chambers, half of the partitions are solid plates, and the other half is a sieve plate with evenly distributed through holes, and the adjacent mixing chambers are connected through the sieve plate; the middle part of the partition plate is pierced with a center The length of the central tube matches the length of the cylindrical shell, and the end close to the discharge pipe is sealed, and the end close to the feed pipe passes through the cylindrical shell through an elbow. The central tube is provided with air holes in each mixing chamber. ; The upper part of each mixing chamber is provided with an exhaust pipe. A colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com