Operating device with gate shafts

A technology of manipulating device and chute, applied to components with teeth, transmission device control, belt/chain/gear, etc., can solve the problems of complex structure and high cost, and achieve the effect of small actuation power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

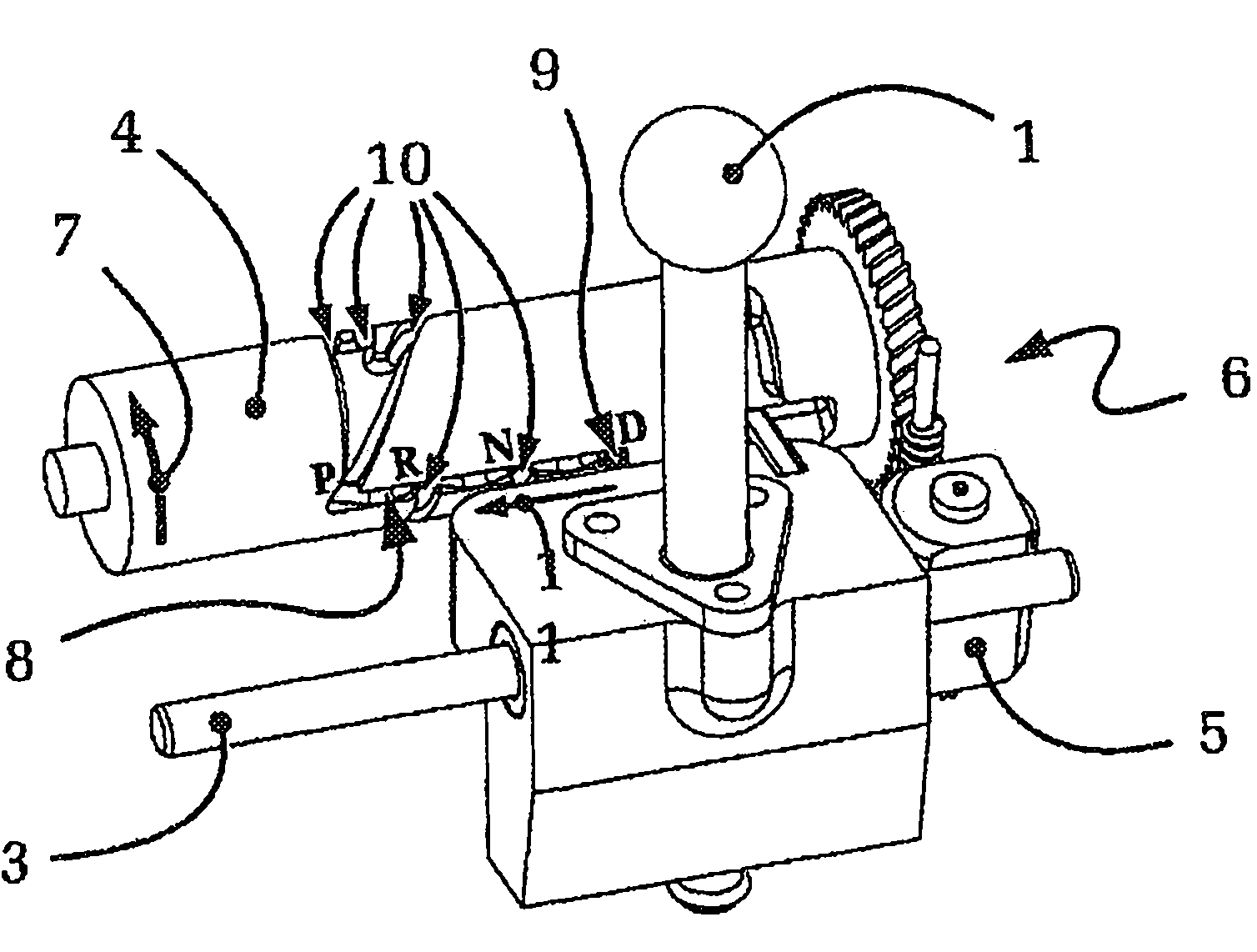

[0044] figure 1 An embodiment of the operating device according to the invention is shown in a schematically completed isometric illustration. One first recognizes the shift lever 1 and the base 2 of the operating device, with the support shaft 3 arranged thereon for the shift lever 1 and with the sliding groove shaft 4 also arranged on the base 2. The chute shaft 4 can be rotated about its longitudinal axis in the direction of the arrow 7 by means of a servo motor 5 using a worm gear 6.

[0045] in figure 1 What happens to be recognizable in figure 1 The locking slide 8 for the shift lever 1 on the slide shaft 7 in the "9 o'clock (9:00Uhr)" position, and the locking pin 9 engaged in the locking slide 8, The latching pin 9 is spring-loaded on the shift lever 1 in a guide (not visible) connected to the shift lever 1.

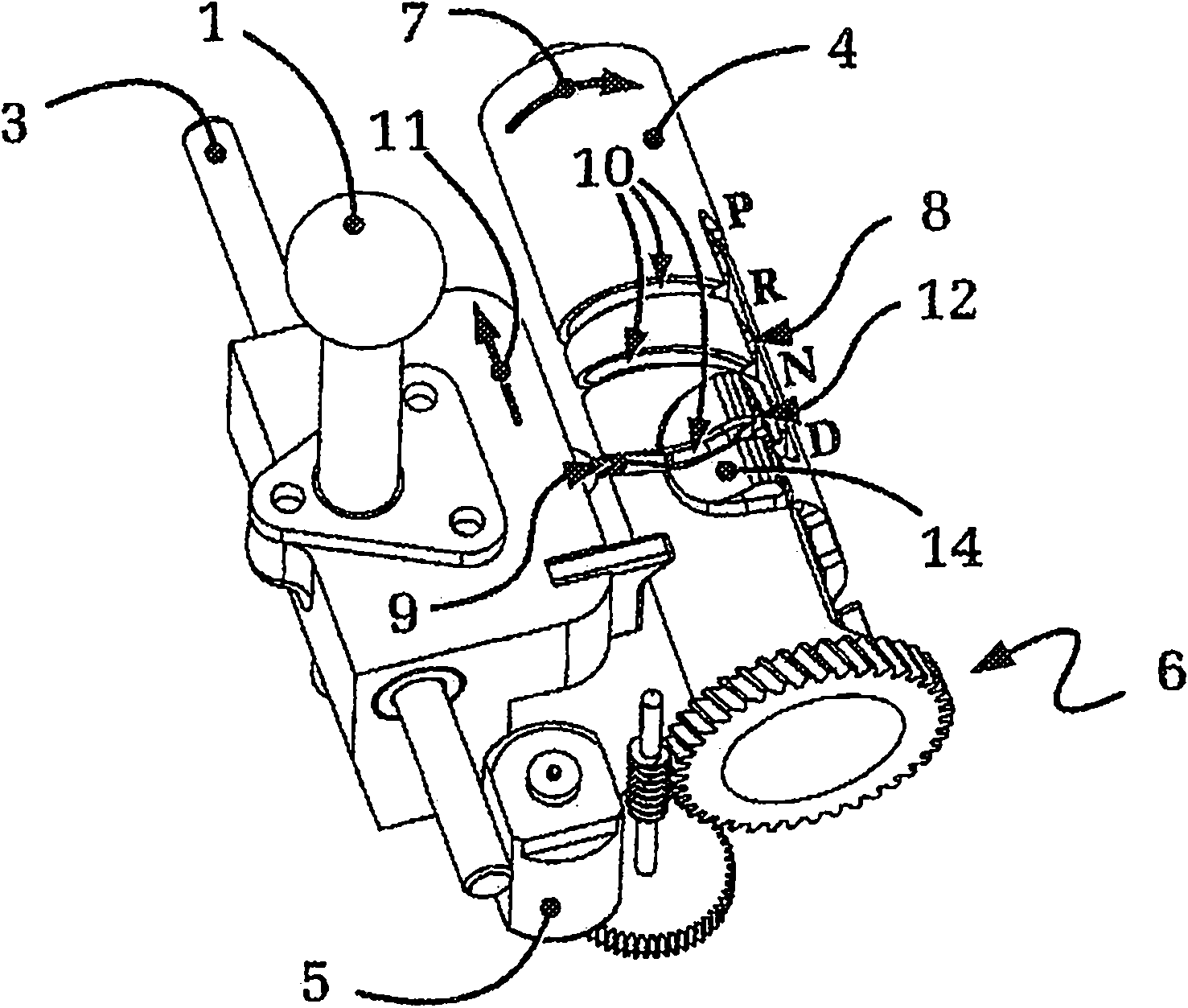

[0046] The locking chute 8 arranged in a recessed manner on the chute shaft 4 or arranged in the chute shaft 4 is in figure 2 It's more visible in the middle. Peop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com