Shell of LED flat-panel TV set

A technology for TVs and flat panels, which is applied to parts of color TVs, parts of TV systems, TVs, etc. It can solve the problems of the back cover being separated from the face shell, and the undisclosed width and narrow dimensions, etc., and achieves a firm structure, smooth and fast installation, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

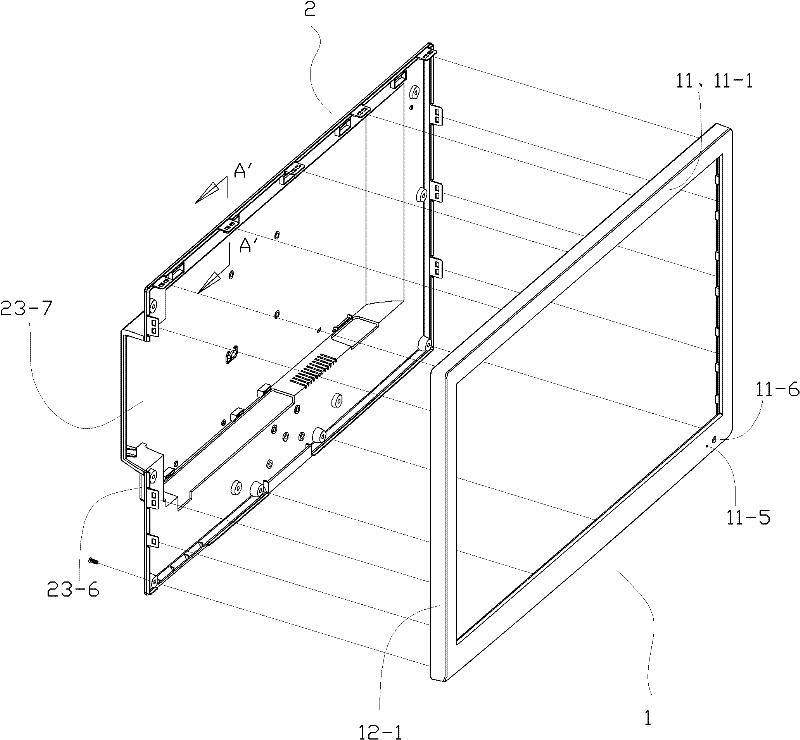

[0045] See figure 1 and figure 2 , The shell of this embodiment includes a front shell 1 and a rear shell 2; the front shell 1 and the rear shell 2 are both injection-molded integral parts.

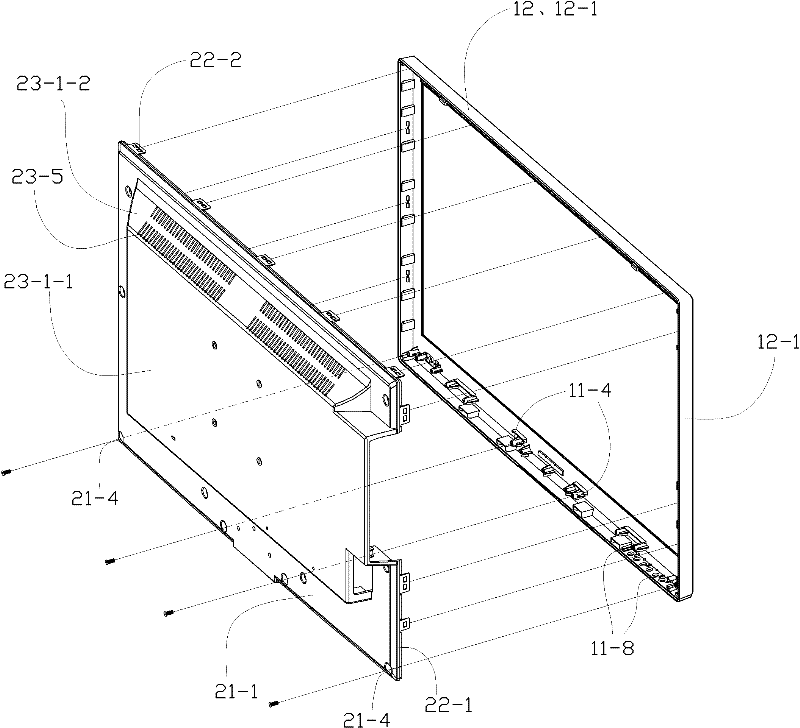

[0046] See Figure 1 to Figure 4 , Image 6 , Figure 7 and Figure 12 , The front case 1 includes a face frame portion 11 and a front case frame portion 12 ; the front case frame portion 12 is connected to the peripheral edges of the face frame portion 11 .

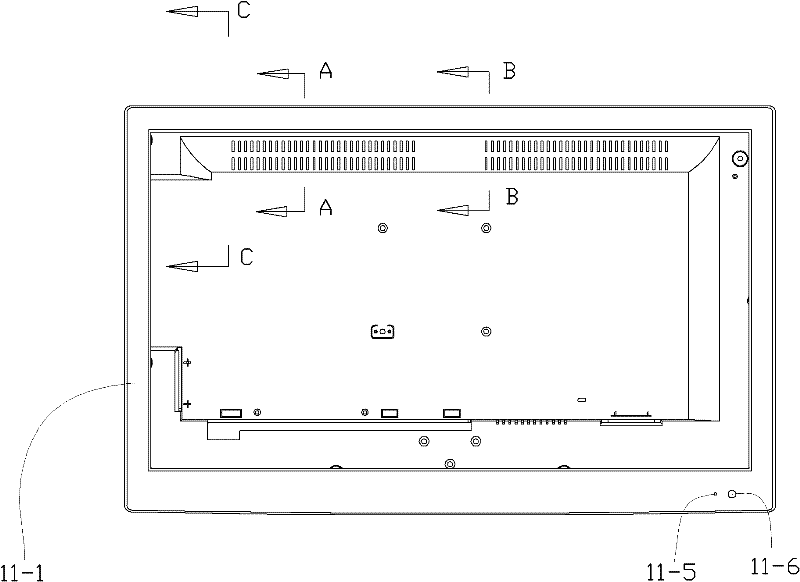

[0047] The face frame part 11 includes a face frame plate body 11-1, a display screen elastic hook group 11-2, a display screen screw post group 11-3, a rear case screw post group 11-4, and a power indicator hole 11-5 , a signal receiving window 11-6 and two module screw posts 11-7. The front frame body 11-1 is composed of four frames, up, down, left, and right, and the board bodies of the four frames are located on the same plane. The front frame part 11 of the front shell 1 has the same frame width on the left and right si...

Embodiment 2)

[0067] See Figure 14 to Figure 17 , the rest of this embodiment is the same as Embodiment 1, the difference is that the front case frame portion 12 also includes 7 to 16 disassembly holes 12-5 (11 in this embodiment), of which 10 disassembly holes 12-5 is arranged in the middle of every group of two fixed blocks 12-2, and another one is arranged on the front portion of a group of fixed blocks 12-2 that only has one fixed block 12-2.

[0068] When disassembling the casing, use a columnar tool to pass through the dismounting hole 12-5 of the front casing frame part 12, and push the elastic gusset 22-2 to the inside of the casing, so that the fixed surface 12-2-3 of the fixed block 12-2 is in line with the elastic The corresponding surface of the clamping hole 22-2-1 of the pinch plate 22-2 is detached, so that the front shell 1 and the rear shell 2 of the casing can be separated more easily, and the disassembly is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com