System and method for internal cooling of a fuel injector

A technology of fuel injectors and injectors, which is applied in fuel injection devices, charging systems, machines/engines, etc., and can solve problems such as increasing fuel temperature, increasing deposit rate by temperature, and increasing temperature of injected fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

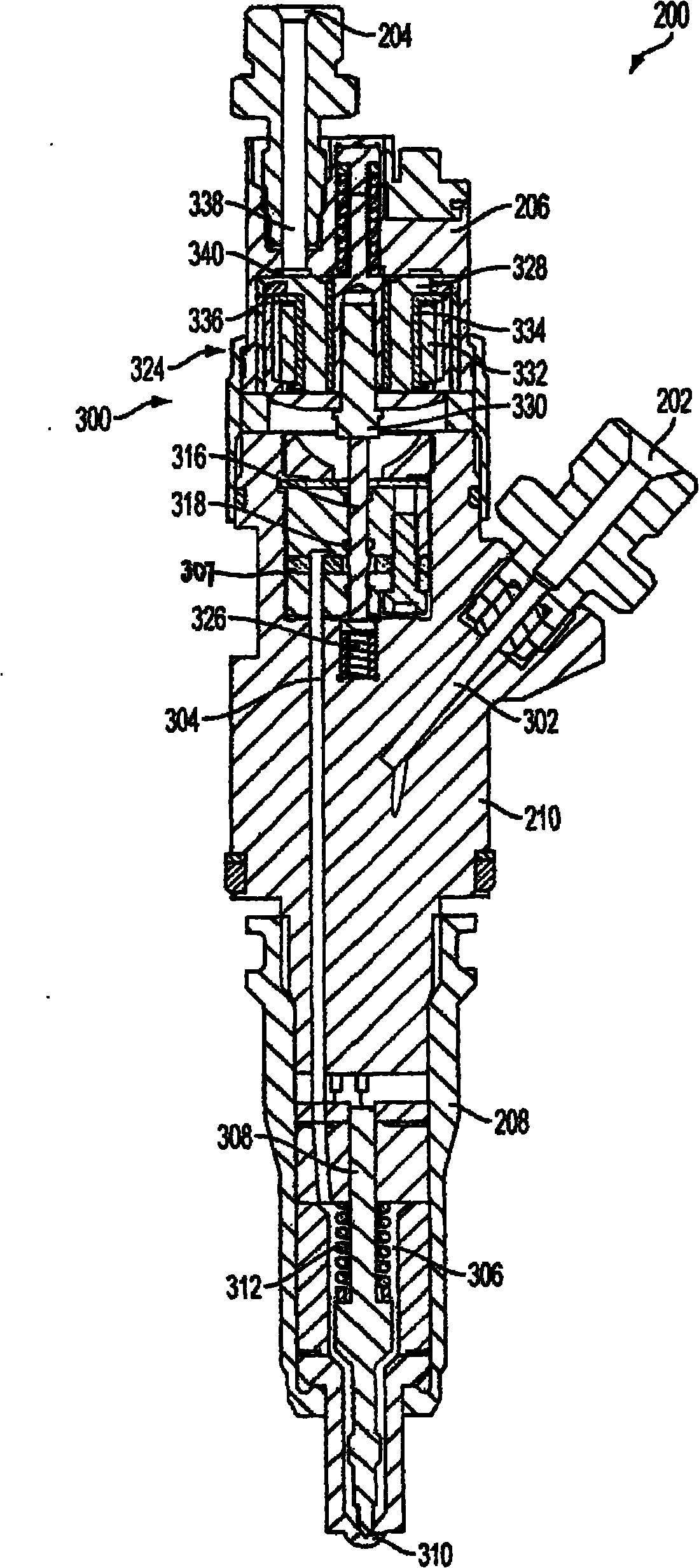

[0018] The systems and methods described herein are used to cool internal components and systems of a fuel injector of an internal combustion engine. This cooling allows the fuel injector to operate at increased injection pressures and further reduces the deposition of debris on internal components of the fuel injector.

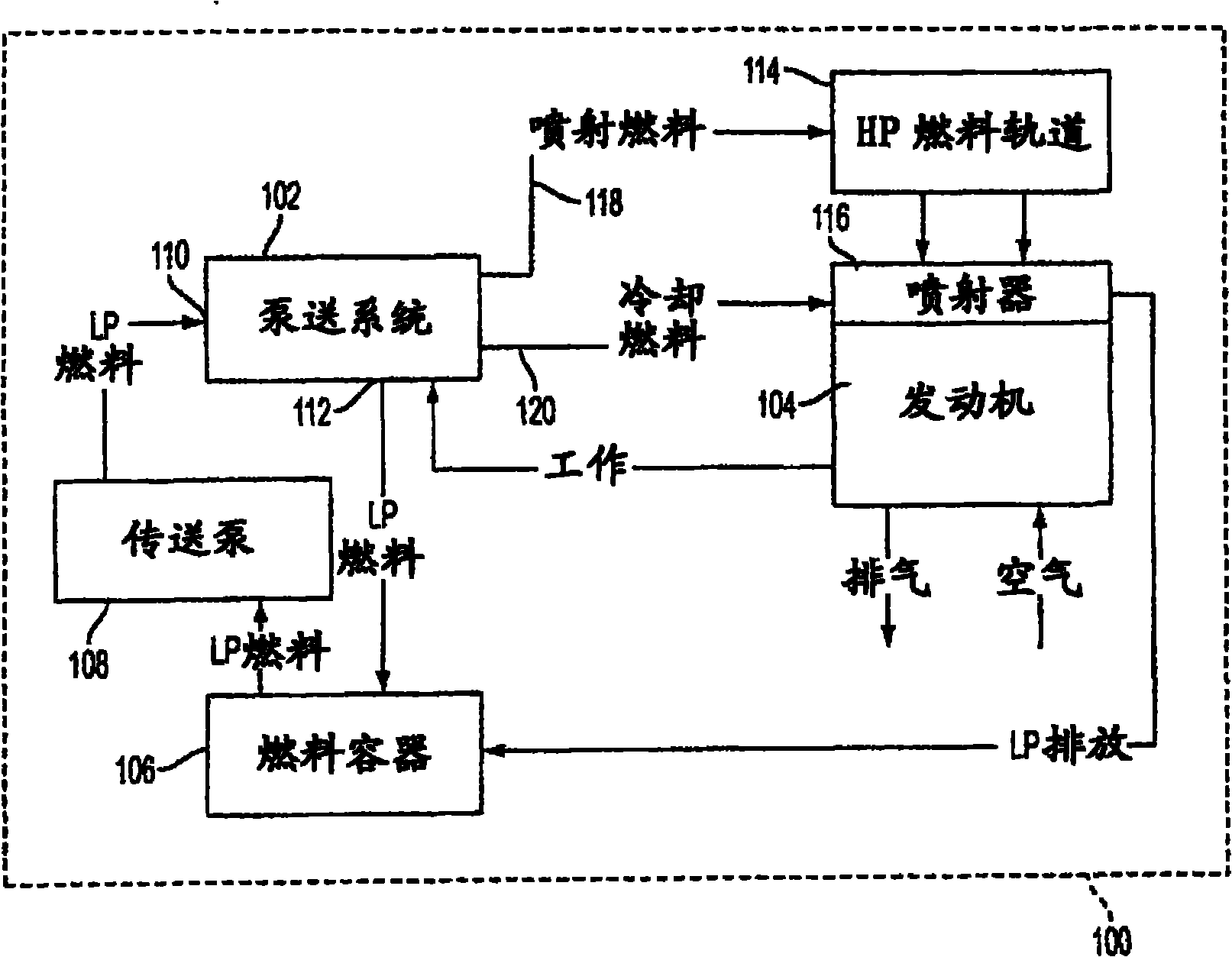

[0019] figure 1 A block diagram of an engine system 100 is shown having a high pressure (HP) fuel pumping system 102 operatively associated therewith. The engine system 100 includes an internal combustion engine 104 connected to the pumping system 102 . Engine 104 may be a compression ignition or diesel engine that mixes air and fuel in multiple combustion chambers during operation. Fuel at low pressure (LP) is supplied to pumping system 102 from a fuel tank or container 106 . A transfer or low pressure pump 108 is provided adjacent to the fuel container to pump fuel from the fuel container 106 and to supply fuel at low pressure to the pumping system 102 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com