High pressure electrolysis cell for hydrogen production from water

A high-voltage electrolysis and electrolysis cell technology, applied in electrolysis components, electrolysis process, electrodes, etc., can solve problems such as damage and impact of electrolysis cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

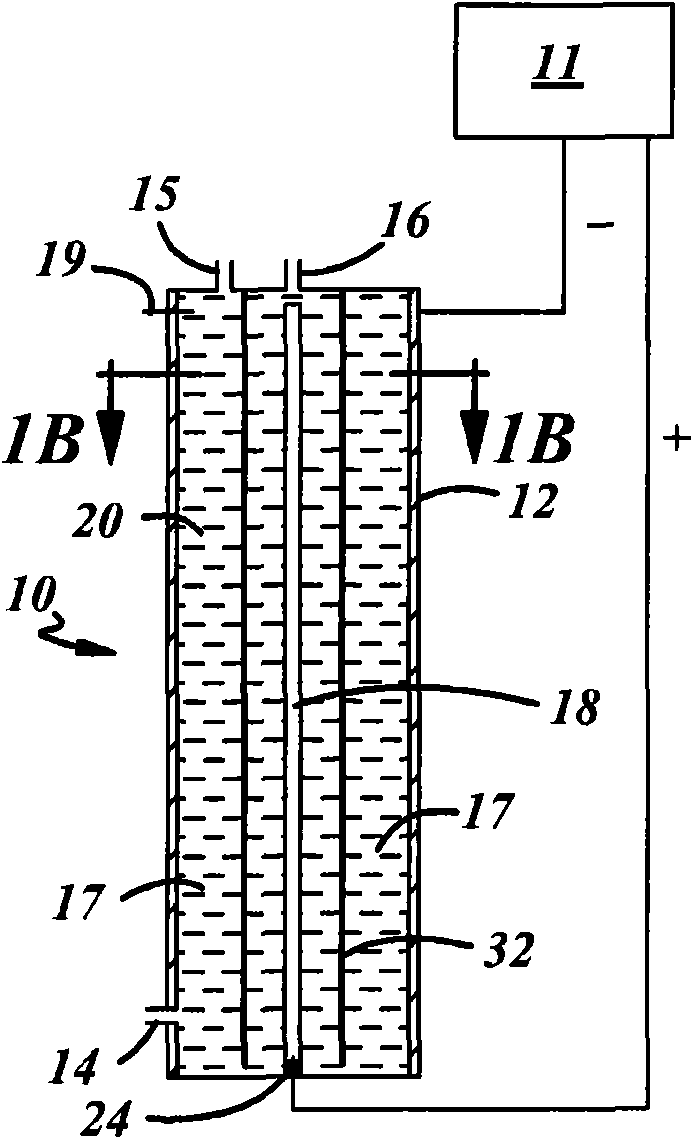

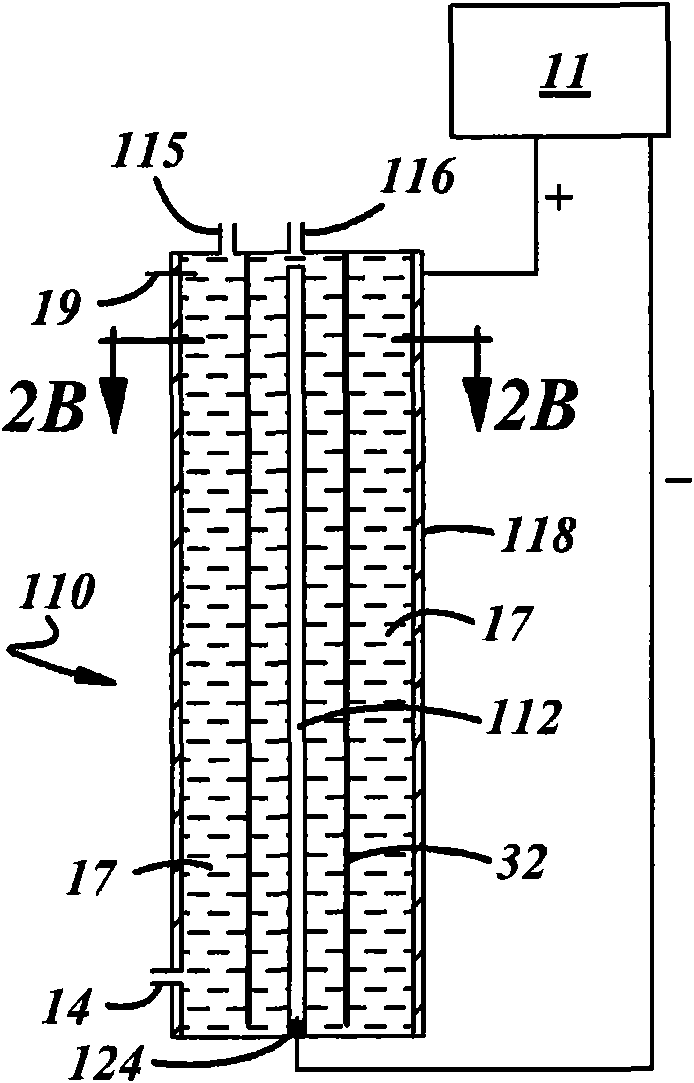

[0075] To illustrate the increase in cell efficiency of the exemplary embodiment cell 110 of FIG. 2 for the cell 10 of FIG. 1 , theoretical calculations of different cell efficiencies can be made based on the assumption that the cells 10, 110 are of the same size. . Additionally, the dimensions of the components were based on measurements made on the Avalence Hydrofiller 50-6500-50RG system described above.

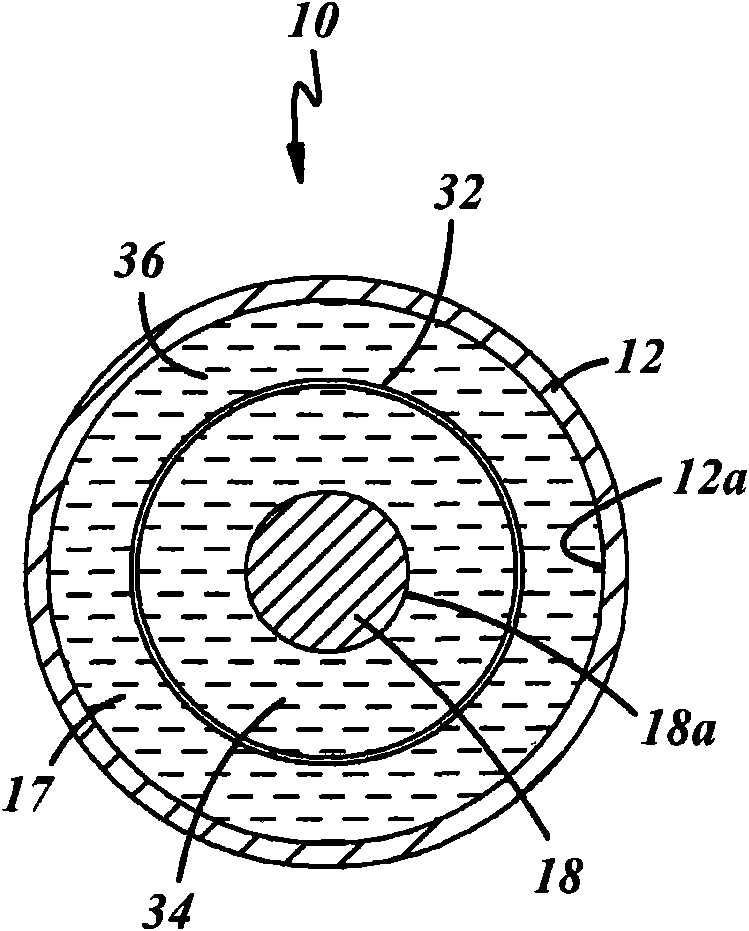

[0076] Therefore, the length (1) of the electrolytic cell 10, 110 is set to approximately 1219 mm. The inner diameter of the outer pressure vessel barrel (i.e., the inner cylindrical surface 12a of the cathode 12 in FIG. 1 and the inner cylindrical surface 118a of the anode 118 in FIG. 2) may be about 42.9 millimeters, which gives a calculated surface area of about 1640 square centimeters. The outer diameter of the conductive center post (ie, the outer cylindrical surface 18a of the anode 18 in FIG. 1 and the outer cylindrical surface 112a of the cathode 12 in FIG. 2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com