Liquid supply vehicle

A liquid supply and vehicle frame technology, which is applied to motor vehicles, goods transport vehicles, and vehicles used for freight transportation, etc. It can solve the problems of reduced plunger pump efficiency, reduced displacement of fracturing vehicles, and reduced fracturing operation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

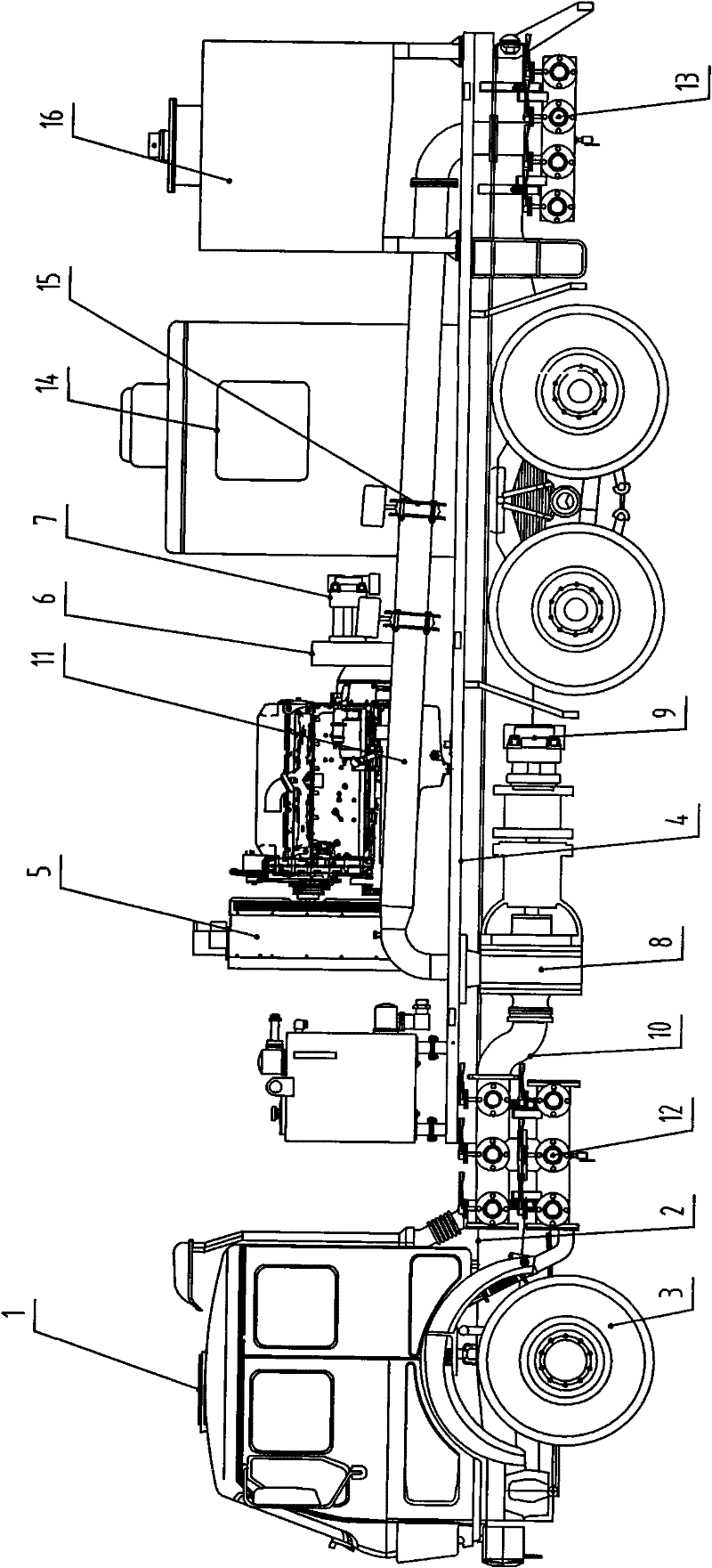

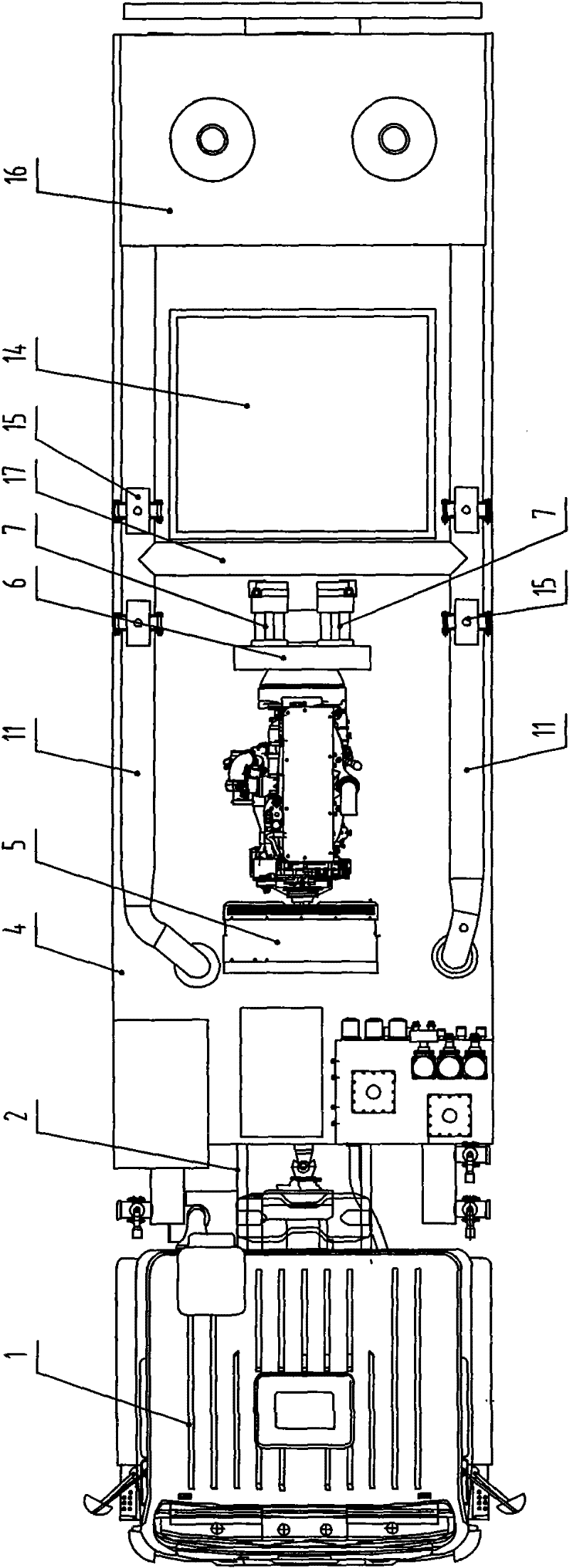

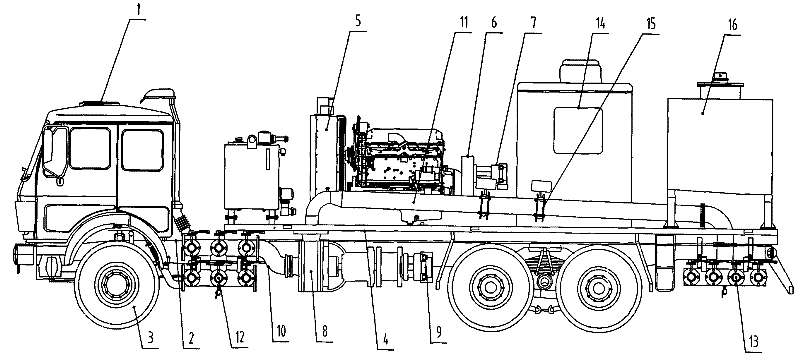

[0012] Such as figure 1 with figure 2 As shown, a liquid supply vehicle of the present invention includes a vehicle frame 2 with a cab 1, wheels 3 are provided at the lower part of the vehicle frame 2, a platform 4 is provided at the rear upper part of the vehicle frame 2, and a power drive is provided on the platform 4. device, the power drive device includes an engine 5, a transfer case 6 and two hydraulic pumps 7, a centrifugal pump 8 is arranged on both sides of the lower part of the platen 4, and the engine 5 is connected to the two hydraulic pumps 7 through the transfer case 6. The two hydraulic pumps 7 are respectively connected to the two centrifugal pumps 8 through a hydraulic motor 9. The inlet and outlet of the two centrifugal pumps 8 are respectively connected with a suction pipe 10 and a discharge pipe 11. The suction port 12 of the suction pipe 10 is located at Below the front part of the platen 4 , the outlet 13 of the discharge pipe 11 is located under the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com