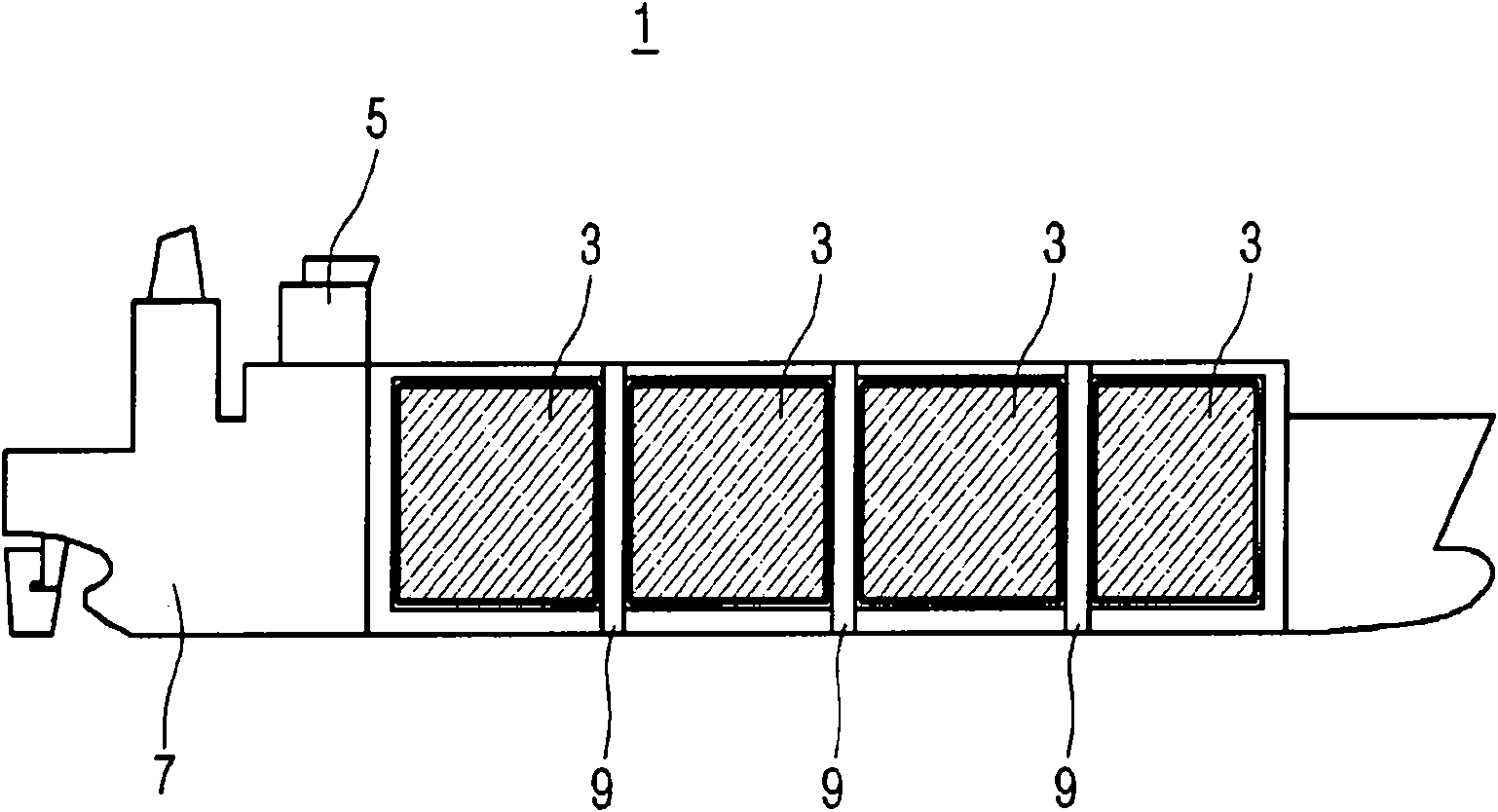

Anti-sloshing structure for lng cargo tank

An anti-sloshing, cargo hold technology, applied in bulk cargo, some tanks in the hull, gas processing/storage purposes, etc., to reduce the sloshing phenomenon and be easy to construct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

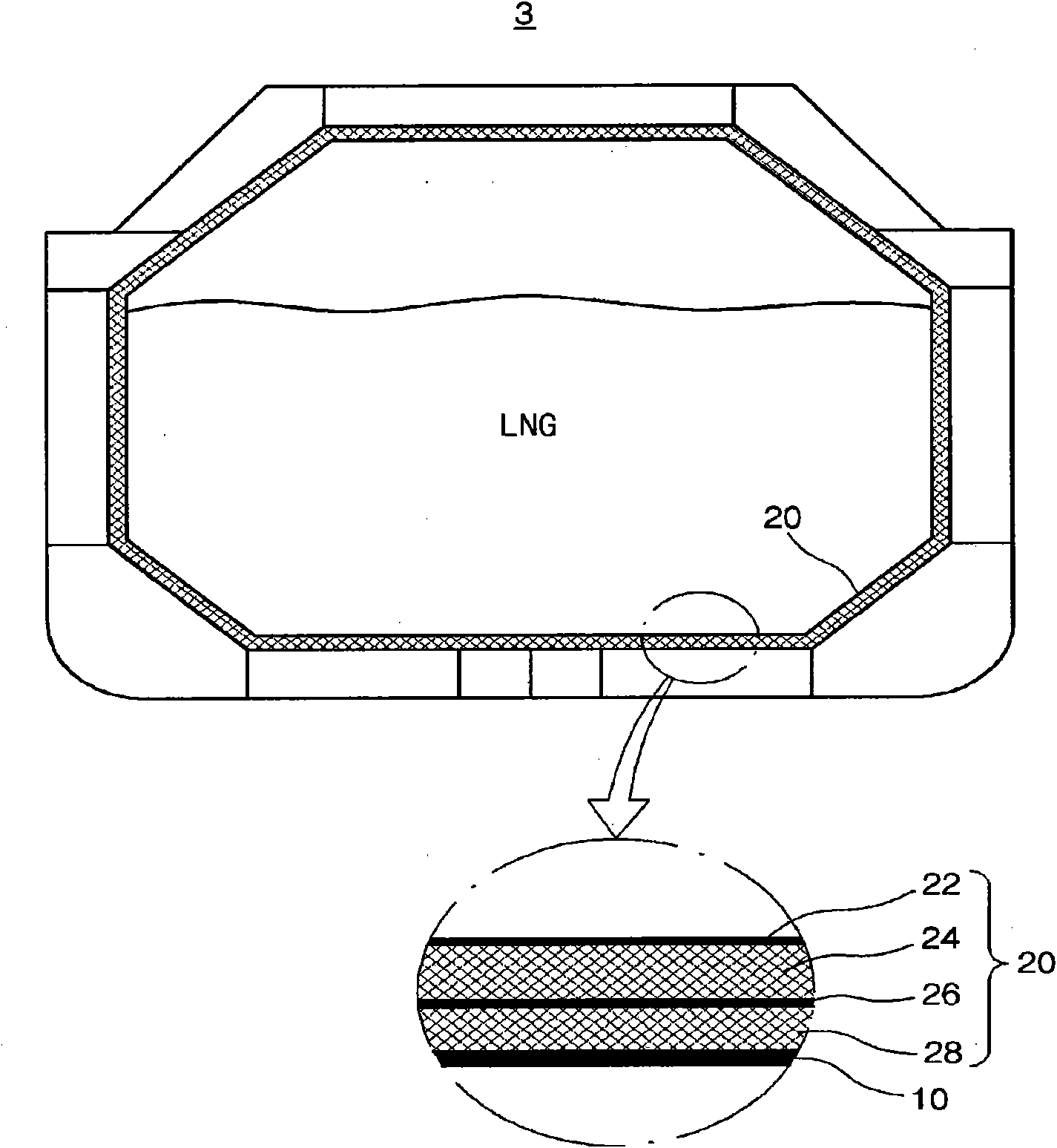

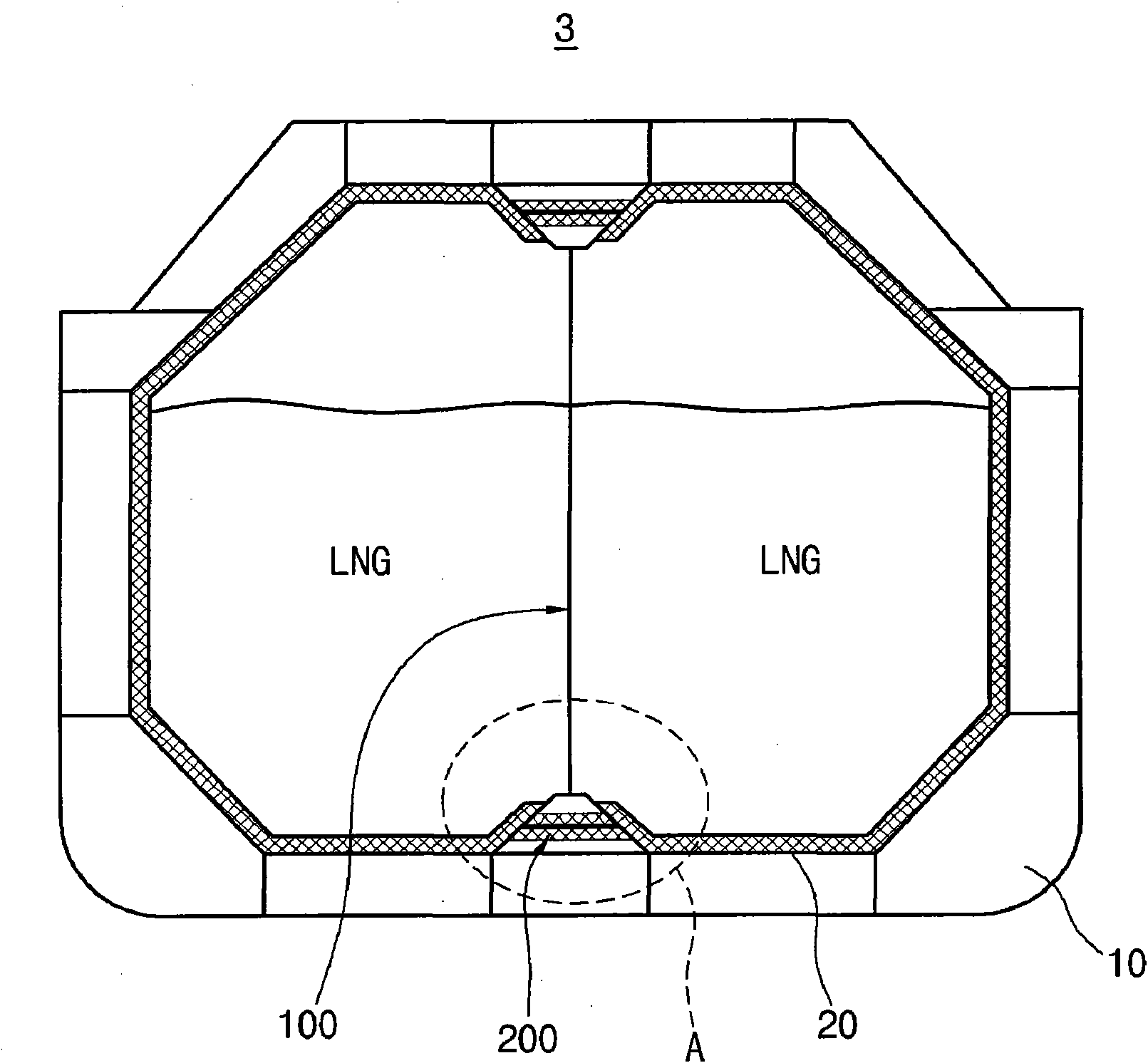

[0039] Preferred embodiments of the anti-sloshing LNG cargo tank according to the present invention are described in detail below.

[0040] image 3 is a view showing an embodiment of the anti-sloshing LNG cargo tank according to the present invention. Figure 4 is shown image 3 A partial perspective view of the first embodiment of the anti-sloshing bulkhead of the embodiment. Figure 5 is shown image 3 A partial perspective view of a second embodiment of the anti-sloshing bulkhead of the embodiment. Figure 6 is shown image 3 An enlarged partial cross-sectional view of the first embodiment of part A of . Figure 7 is shown image 3 An enlarged partial cross-sectional view of the second embodiment of part A of . Figure 8 is shown image 3 An enlarged partial cross-sectional view of the third embodiment of part A of .

[0041] Such as image 3 As shown, the anti-sloshing LNG cargo tank according to the present invention comprises: an anti-sloshing bulkhead 100, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com