Computer graphics method for manufacturing centrifugal rating plate

A drawing method and computer technology, applied in calculation, special data processing applications, instruments, etc., to achieve the effect of reducing drawing time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

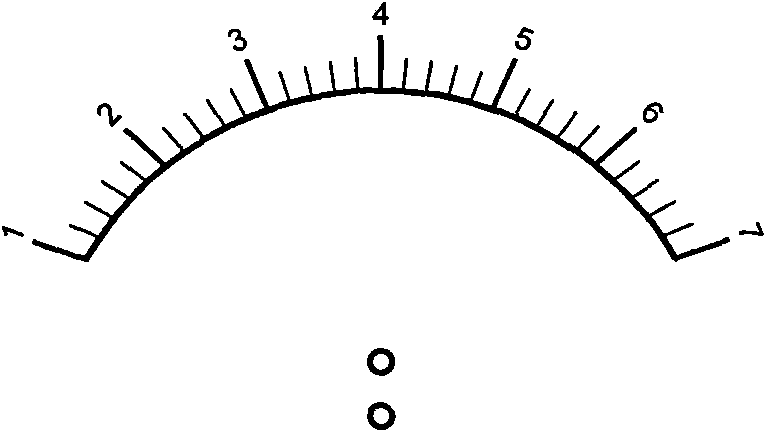

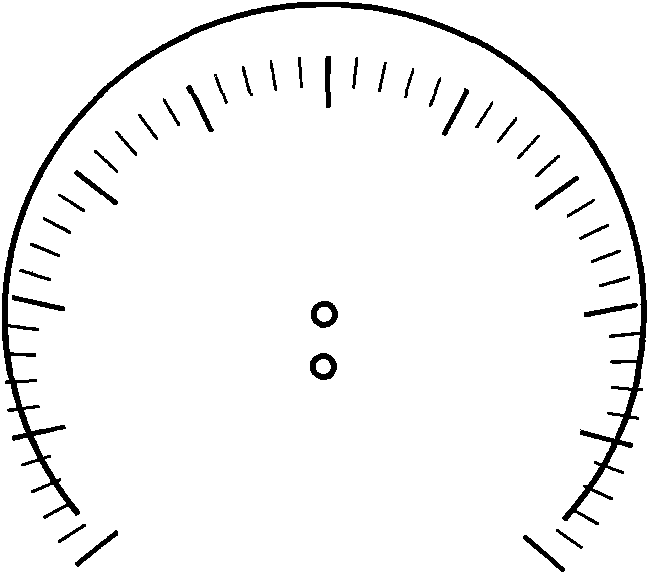

[0031] The sign making system is generally composed of a drawing computer and a laser phototypesetter. The computer and the phototypesetter are interconnected for communication. The computer converts the drawn sign graphic file into a file format compatible with the laser phototypesetter and outputs it to the phototypesetter. The phototypesetter prints out the film production afterwards. The present invention utilizes ObjectARX2008 to carry out secondary development for AutoCAD2008, such as Figure 6 As shown, the centrifugal sign making computer graphics method includes the following steps:

[0032] 1) input arc parameters, including the radius of the arc, the center coordinates, the starting and ending angles, the center coordinates of the scale marks; in the present embodiment, the arc center coordinates are (0,0), the radius is 30mm, and the starting point The ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com