Primary measurement shell for measurement while-drilling instrument

A technology of measurement while drilling and instruments, which is applied in the directions of measurement, earthwork drilling, borehole/well components, etc., and can solve problems such as inability to operate the measurement subsystem, difficulty in installation and disassembly, and failure to adopt circumferential layout structure design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

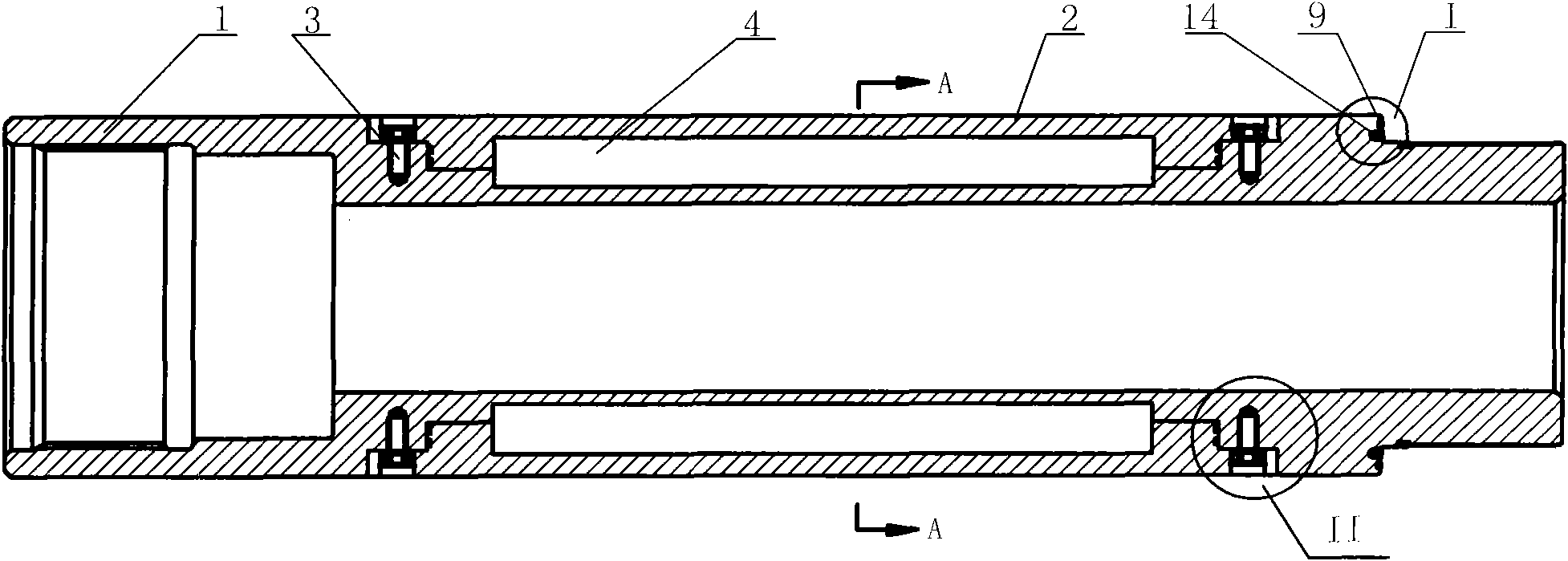

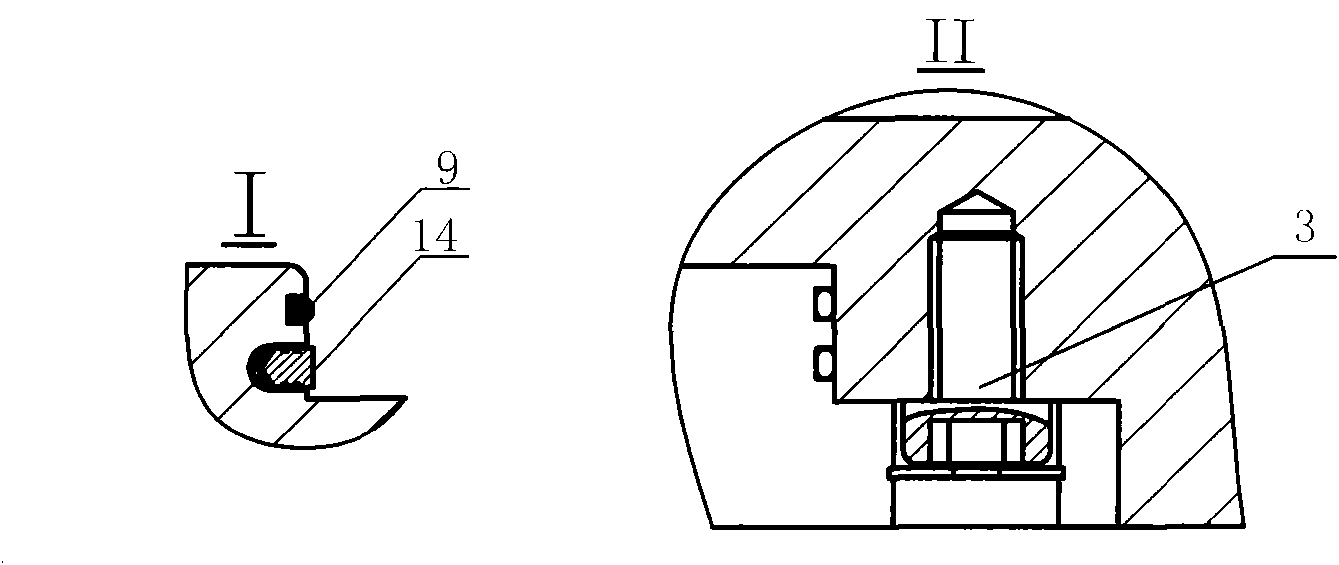

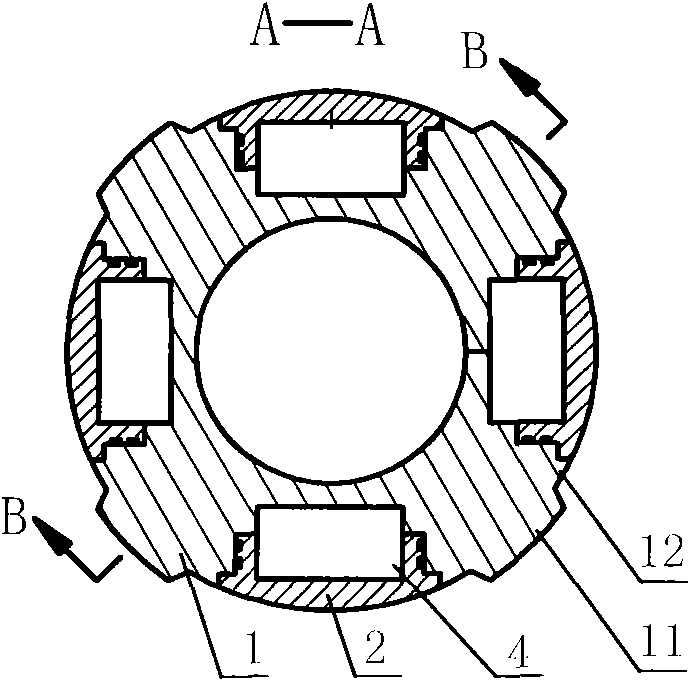

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

[0020] Depend on figure 1 to combine figure 2 , image 3 As shown, the main measuring housing used for the measuring instrument while drilling includes a short joint body 1, a buckle cover 2, and a conductive ring 14; wherein the short joint body 1 is evenly milled with alternating convex walls 11 along the circumferential direction, and the convex wall 11 Quantity is identical with the quantity of the instrument of measuring while drilling to be placed, preferably 4, forms recessed wall 12 between convex wall 11, is milled with stepped groove on recessed wall 12, and the structure of buckle cover 2 is corresponding to the structure of stepped groove, The buckle cover 2 is buckled on the stepped groove, and fixed with fastening screws and snap rings 3. The joint of the buckle cover 2 and the sub body 1 is prefabricated with an instrument cabin 4, which can be in various...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com