Rapid solution construction method for rock salt cavity

A technology of salt rock karst cavity and construction method, which is applied in the fields of high-efficiency and low-cost construction of salt karst cavity, mining of underground salt deposits, construction of salt karst cavity, and rapid dissolution of salt minerals. It can solve the problems of high construction cost, long construction time, Low production efficiency and other issues, to achieve the effect of increasing the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

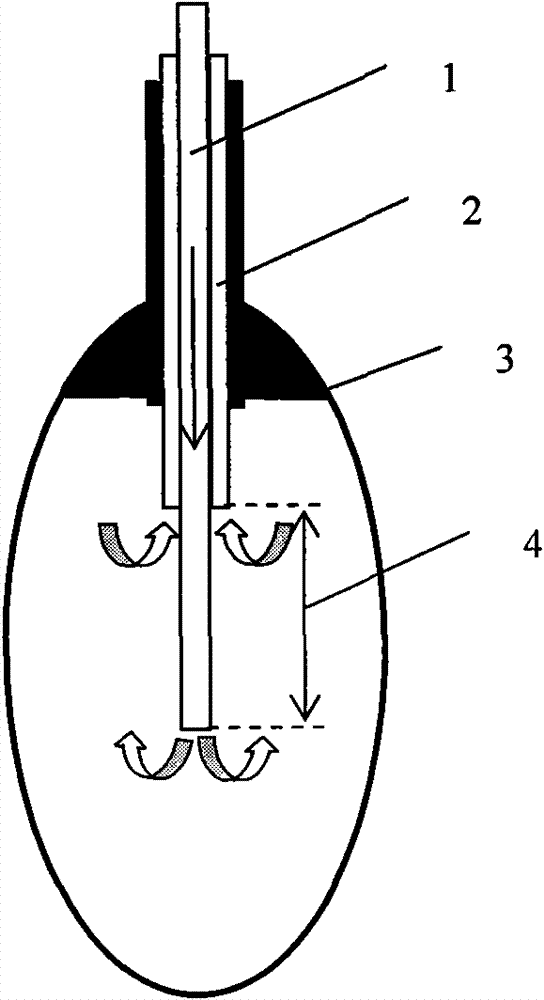

[0020] refer to figure 1 , 2 as shown,

[0021] A method for constructing a fast-dissolving salt karst cavity, the steps of which are:

[0022] (1) Drill a single well from the surface to the target deposit;

[0023] (2) After the installation of the pipe string system is completed according to the conventional method, at the initial stage of cavity dissolution construction, the distance between the two nozzles is 25m, and the positive circulation method is adopted to inject water from the center pipe and produce brine from the middle pipe;

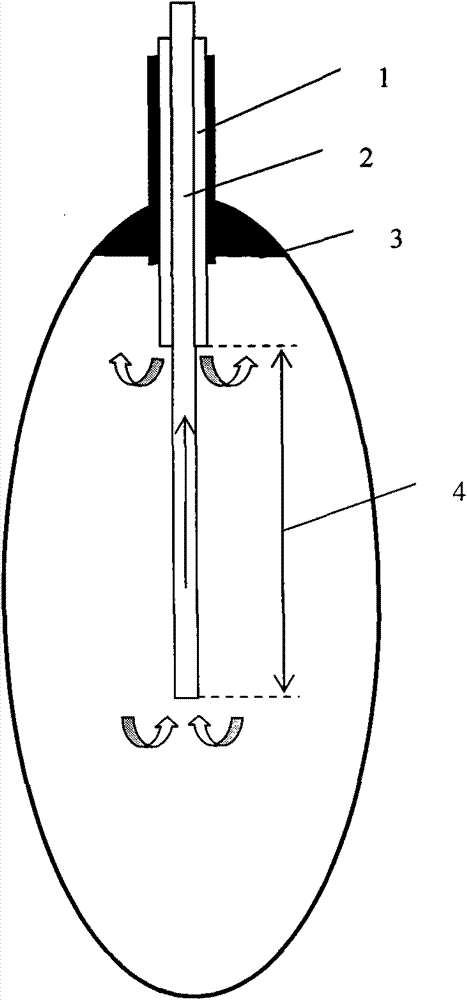

[0024] (3) The construction of the cavity starts from the bottom of the cavity first, and then enters the construction stage of the main body of the cavity. The radius of the cavity gradually increases to 30m, and the distance between the two pipes is 45m. The reverse circulation method is used to inject fresh water from the middle pipe, and the center Pipe brine for production;

[0025] (4) In the main stage of cavity construction, t...

Embodiment approach 2

[0028] refer to figure 1 , 2 as shown,

[0029] A method for constructing a fast-dissolving salt karst cavity, the steps of which are:

[0030] (1) Drill a single well from the surface to the target deposit;

[0031] (2) After the installation of the pipe string system is completed according to the conventional method, at the initial stage of cavity dissolution and construction, the distance between the two nozzles is 30m, and the positive circulation method is adopted to inject water from the center pipe and discharge brine from the middle pipe for production;

[0032] (3) When the cavity is constructed, the bottom of the cavity is constructed first, and then the main body of the cavity is constructed. The radius of the cavity gradually increases to 30m, and the distance between the two pipes is 50m. The reverse circulation method is adopted, and fresh water is injected from the middle pipe and out of the central pipe. brine for production;

[0033] (4) In the main stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com