Butyronitrile canvas filler rubber and preparation method and application thereof

A cloth rubber and nitrile rubber technology, which is applied in the field of nitrile cloth rubber and its preparation, can solve the problem that the height and dimension of a single V-ring are difficult to control precisely, the height deviation in the circumferential direction of the product is large, and the height of one side or part exceeds the limit. Poor and other problems, to achieve the effect of improving stress relaxation performance, long storage period, and avoiding pad height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0033] Embodiment 1~3 and comparative example 1~4 carry out according to the following steps:

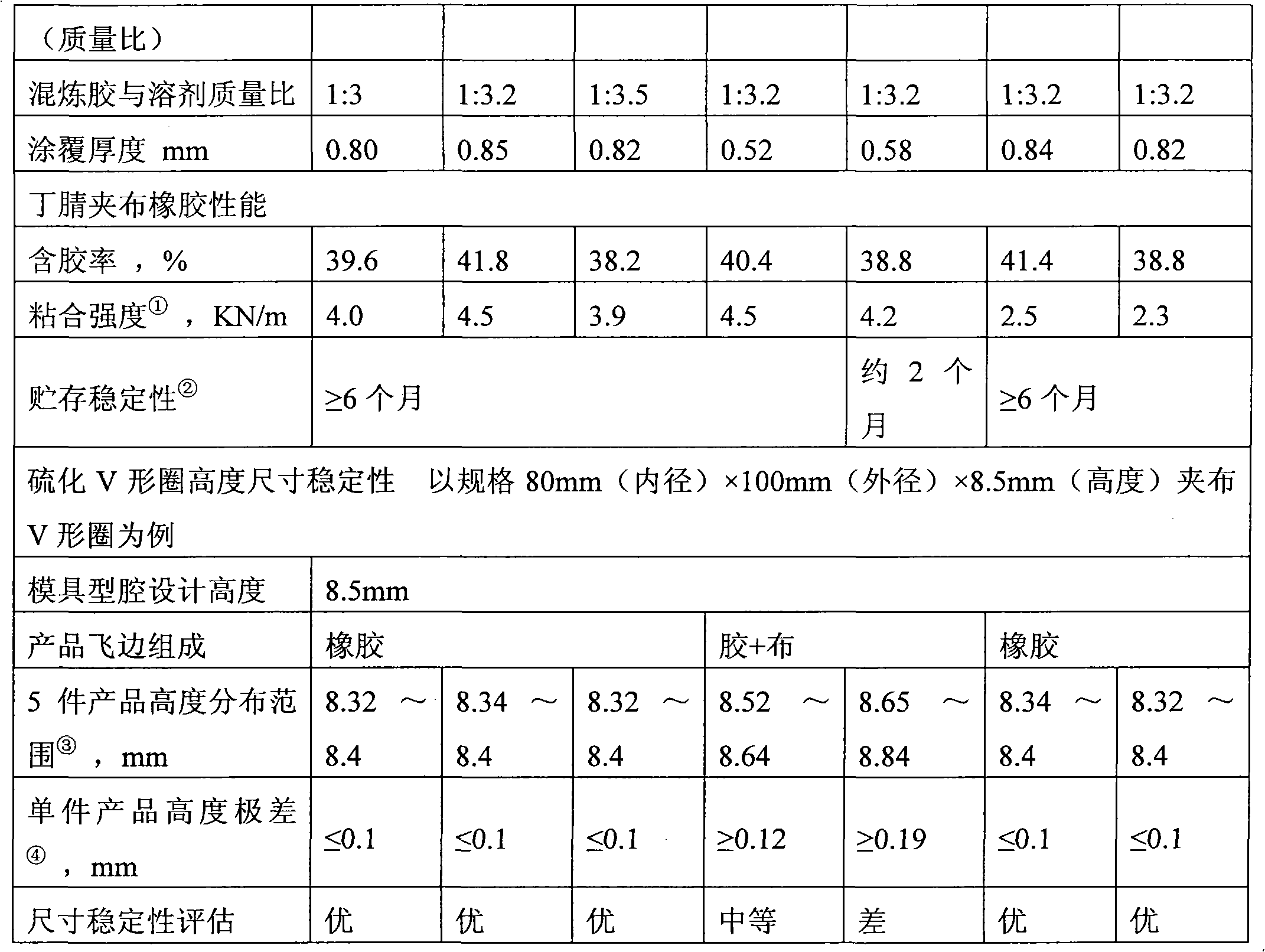

[0034] (1) Preparation of nitrile butadiene rubber compound: used ingredients and consumption are as shown in table 1, by the conventional production process of compound rubber in the rubber industry, after using open mill or internal mixer to mix evenly, obtain nitrile butadiene rubber Rubber compounds, 6 kinds of nitrile rubber compounds were prepared.

[0035] (2) Preparation of nitrile cloth rubber: Thin the nitrile rubber compounded rubber obtained in step (1) into thin slices of 0.5-2 mm, separate them into strips, place them in a mixer with a mixed solvent, and stir for 2-4 hours Obtain acrylonitrile-butadiene glue at last, the obtained acrylonitrile-butadiene rubber glue is coated on cotton canvas, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com