Glass fiber cloth singeing technology and production mechanism using same

A technology of glass fiber cloth and glass fiber, which is applied in the field of glass fiber cloth singeing technology and the production mechanism using this technology, which can solve the problems of removing glass fiber cloth and affecting the quality of copper clad laminates, etc., and achieves good singeing effect and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

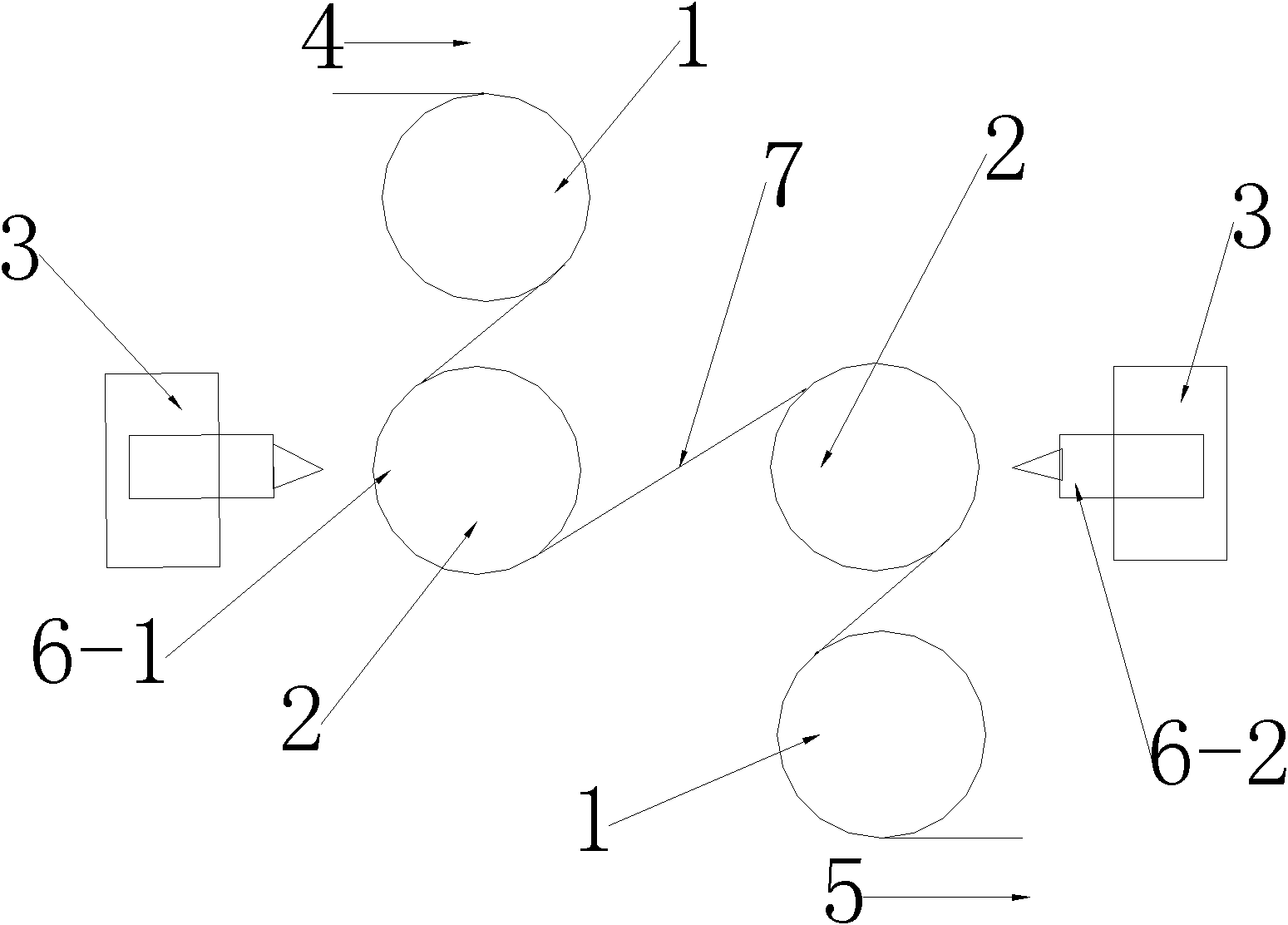

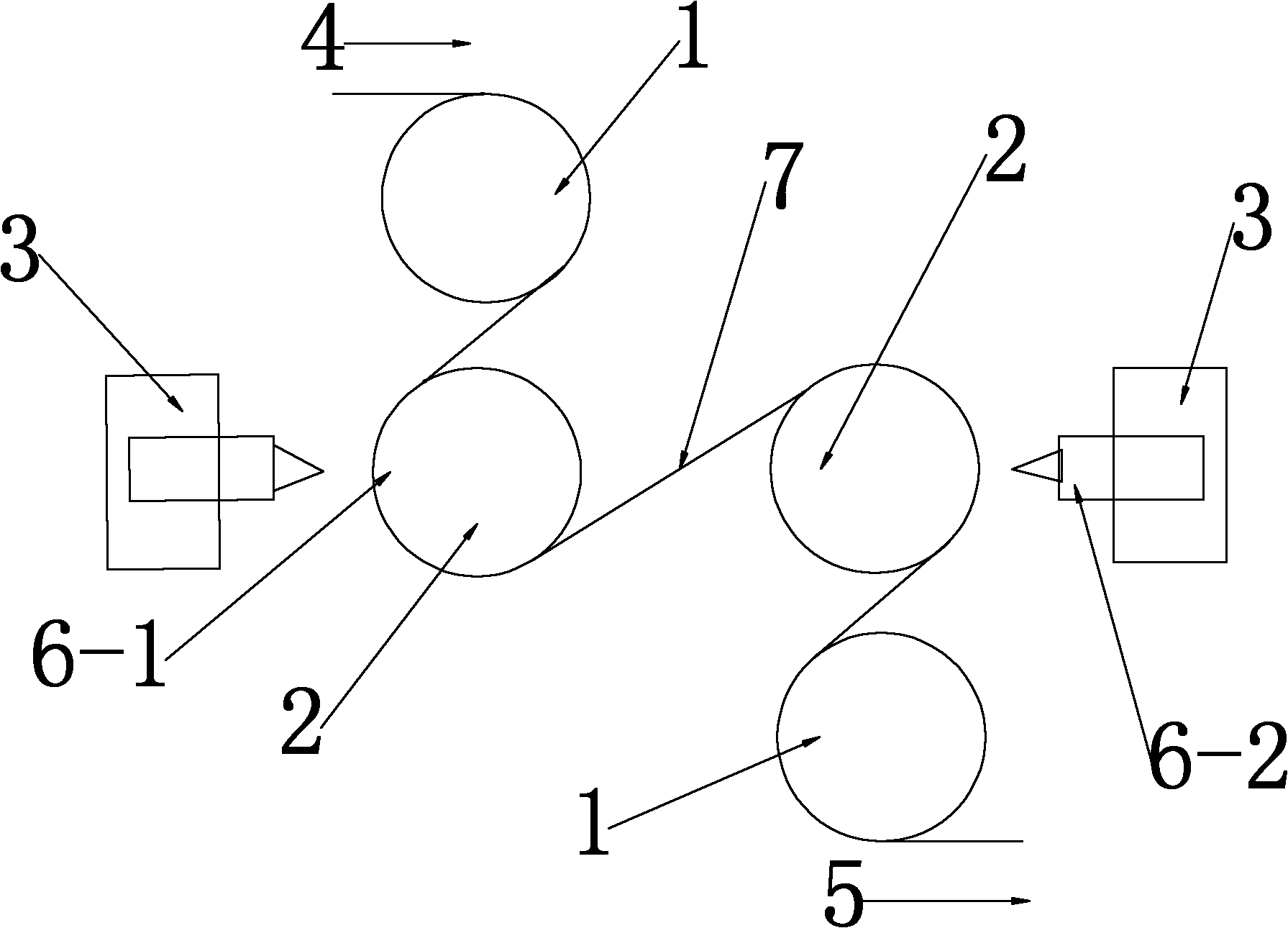

[0015] Such as figure 1 As shown, the singeing mechanism of glass fiber cloth described in this embodiment mainly includes a transmission roller 1, a cloth inlet 4 and a cloth outlet 5, and two transmission rollers are arranged between the cloth inlet 4 and the cloth outlet 5 1. A left singeing device 6-1 and a right singeing device 6-2 are arranged opposite to each other between the two conveying rollers 1, and both the left singeing device 6-1 and the right singeing device 6-2 include a singeing roller 2 With a row of spray guns 3, the spray gun 3 of the left singeing device 6-1 is arranged on the left side of the singeing roller 2, and the spray gun 3 of the right singeing device 6-2 is arranged on the right side of the singeing roller 2. And the direction of rotation of the two singeing rollers 2 is opposite, and the spray guns 3 are arranged side by side and evenly, and the total length of the spray guns 3 side by side is slightly greater than the length of the singeing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com