Steel/aluminum belt automatic deviation correction device

An automatic deviation correcting device and aluminum strip technology, applied in the field of deviation correcting devices, can solve problems such as the deviation of the steel/aluminum-plastic composite belt from the center, restricting the first-time pass rate of products, and the inability of employees to correct on-site, so as to improve the first-time pass rate and avoid Broken belt phenomenon, to ensure the effect of normal conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

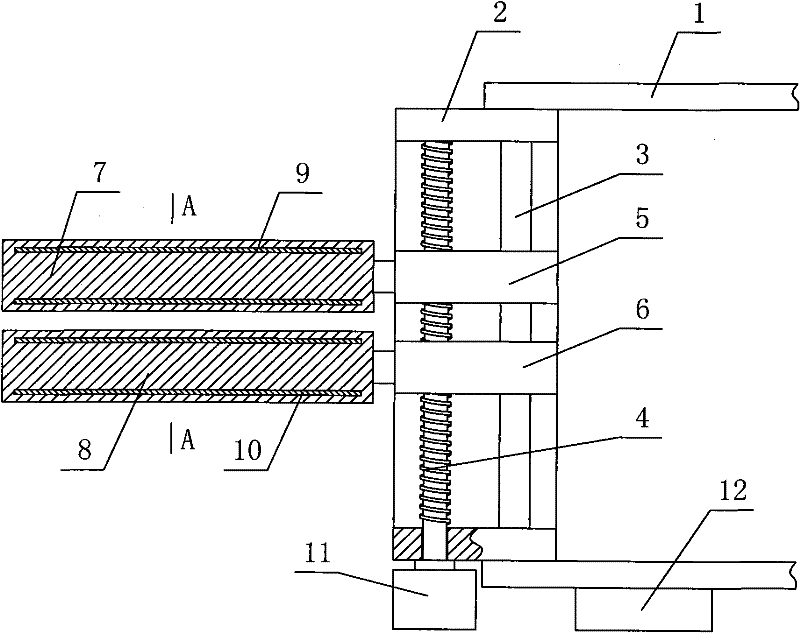

[0010] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

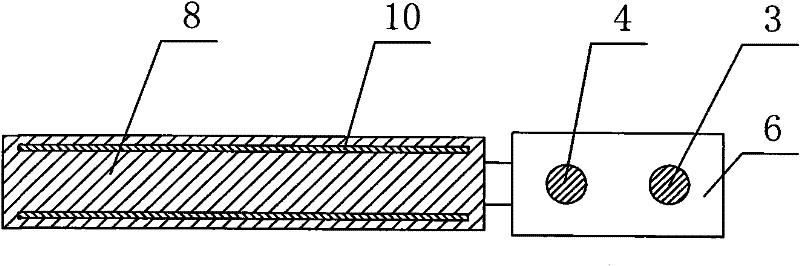

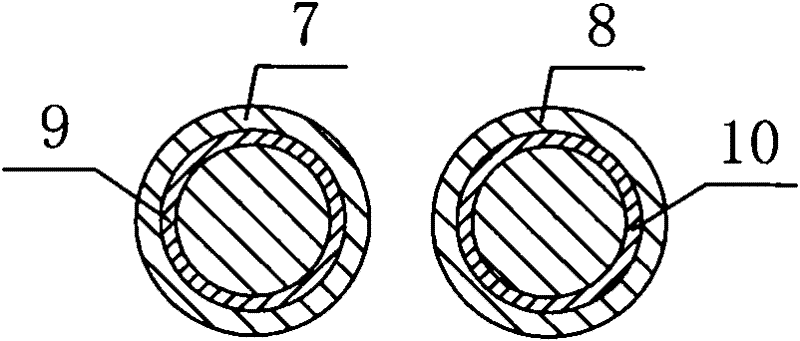

[0011] Such as Figure 1~3 As shown, the present invention includes a support 1, a support base 2 is fixedly connected to the front end of the support 1, and a fixed support slide bar 3 and a threaded rod 4 that is movably arranged are arranged in parallel on the support base 2. Two parallel left fixed blocks 5 and right fixed blocks 6 that are simultaneously sleeved on the support slide bar 3 and the threaded rod 4 are installed on the threaded rod 4, and are respectively fixedly connected with a Rotatable left guide rail 7 and right guide rail 8 perpendicular to support slide bar 3 and threaded rod 4, left guide rail 7 and right guide rail 8 are parallel to each other and are provided with gap between, are respectively provided with inside left guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com