Oral solution bottle cover automatic adjusting mechanism

An automatic adjustment and oral liquid technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low degree of automation, unguaranteed product quality, high labor cost, etc., and achieve good friction effect and good adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

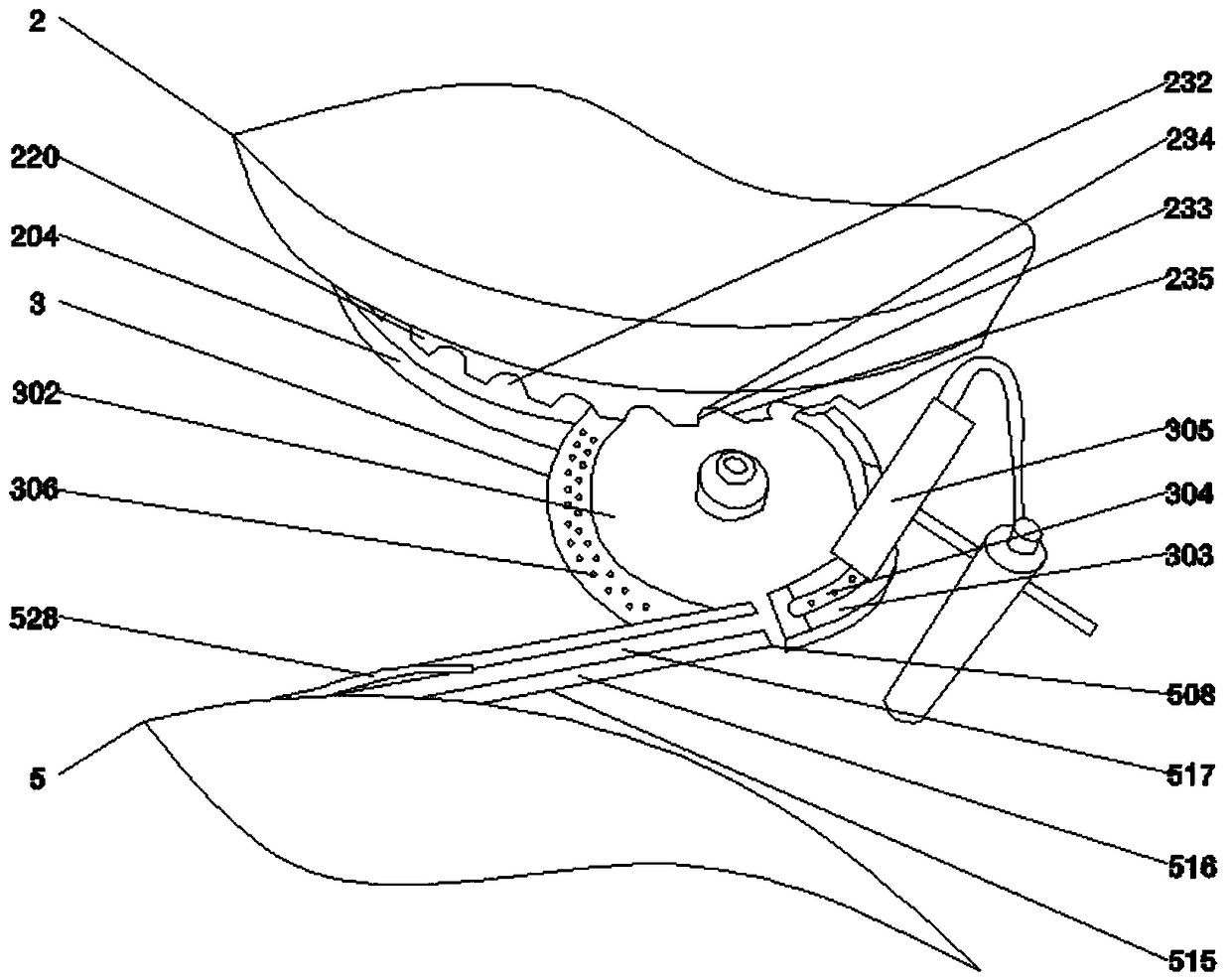

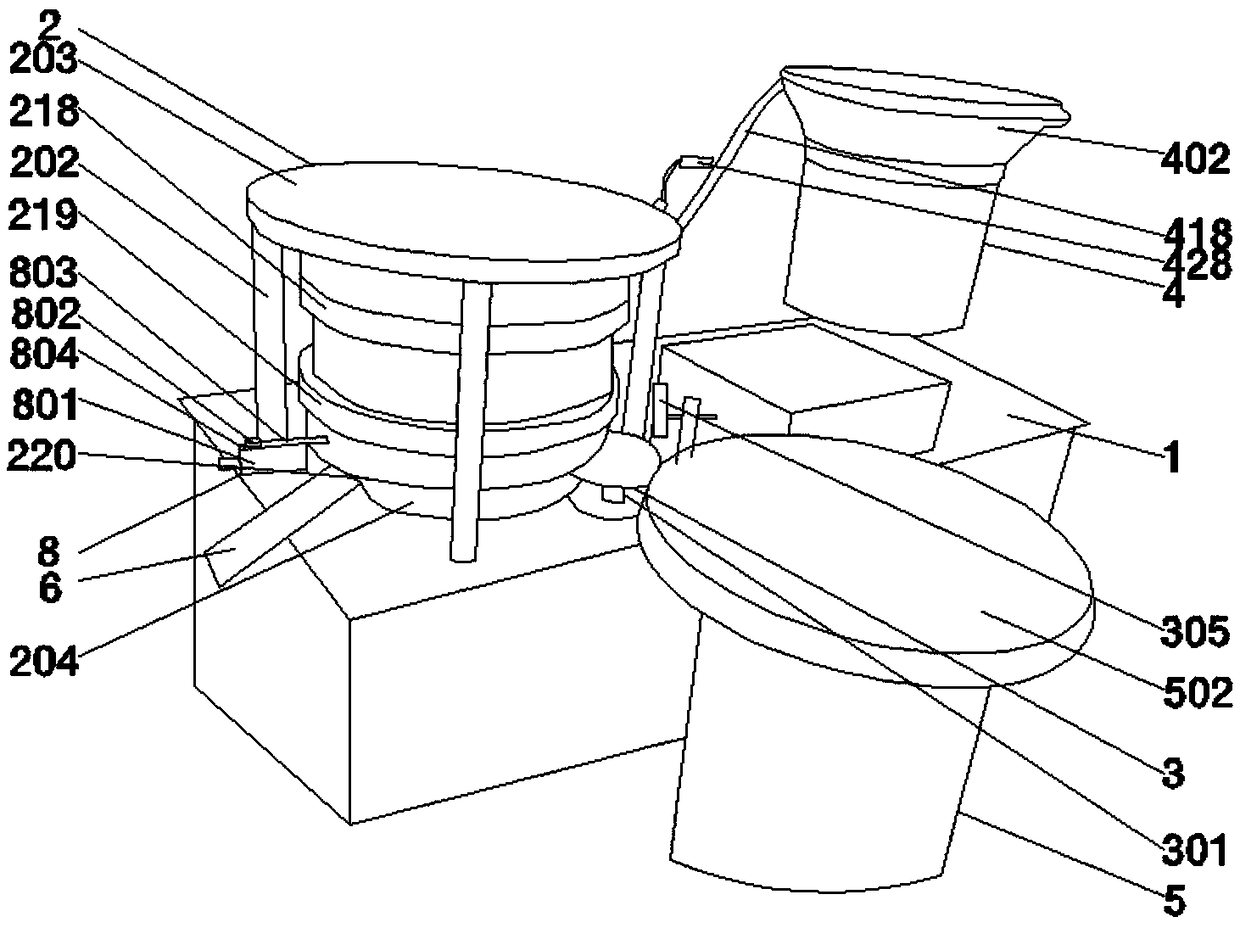

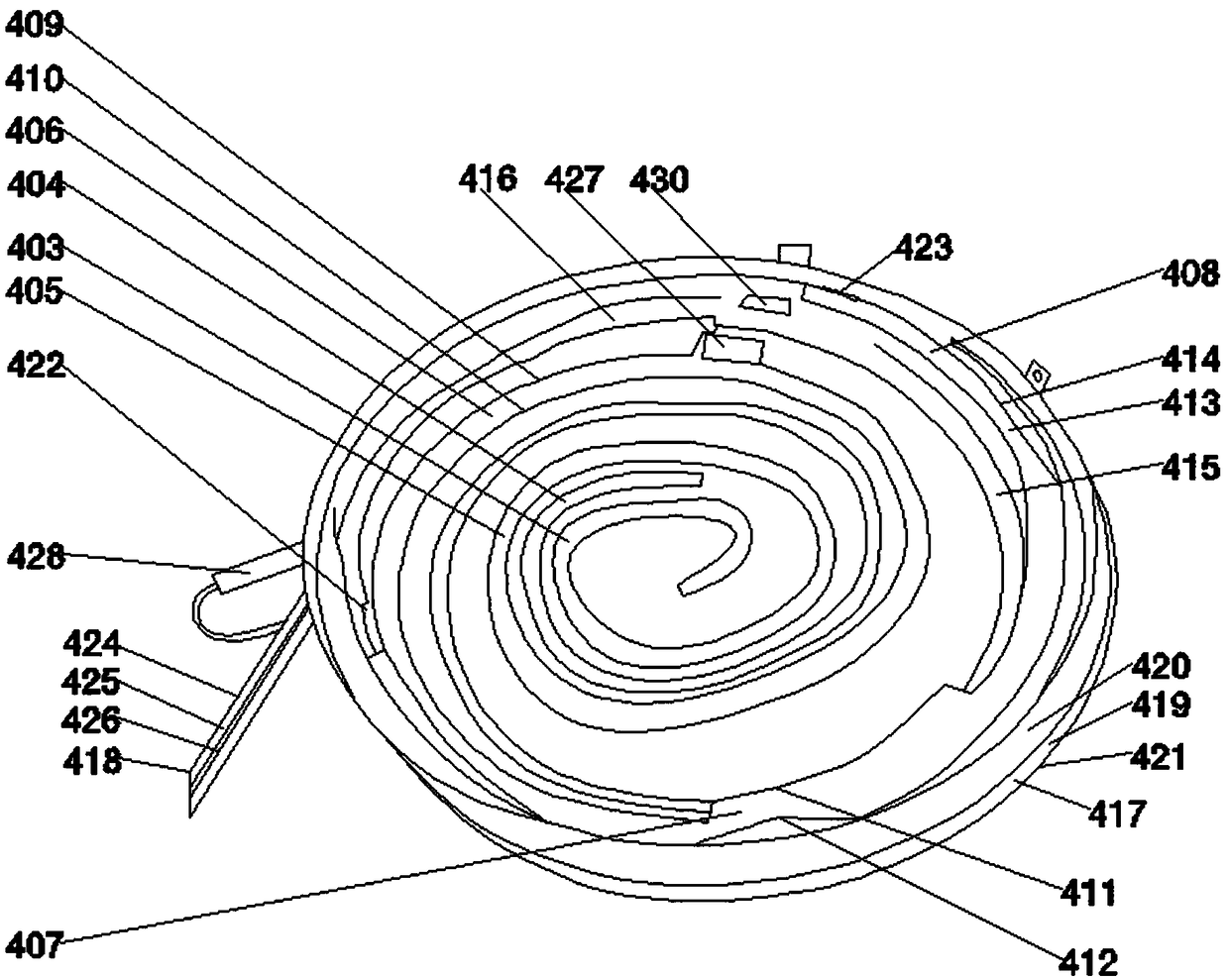

[0030] Such as figure 1 The oral liquid bottle cap automatic adjustment mechanism shown includes a bracket 1, an adjustment motor 301 arranged on the bracket and an adjustment disc 302 arranged on the output shaft of the adjustment motor. The upper end surface of the adjustment disc is a stepped surface structure, and A semi-circular adjustment track 303 is provided through the strut, the adjustment track is located above the outer step surface of the adjustment disc, the width of the adjustment track is the same as the width of the outer step surface of the adjustment disc, and the longitudinal section of the adjustment track is a U-shaped surface. The top of the adjustment track is provided with an arc-shaped observation hole 304, the entrance of the adjustment track is located at the output end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com