Rubber stopper conveying device in assembly process of oral liquid bottle cap

A technology of assembly process and conveying equipment, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

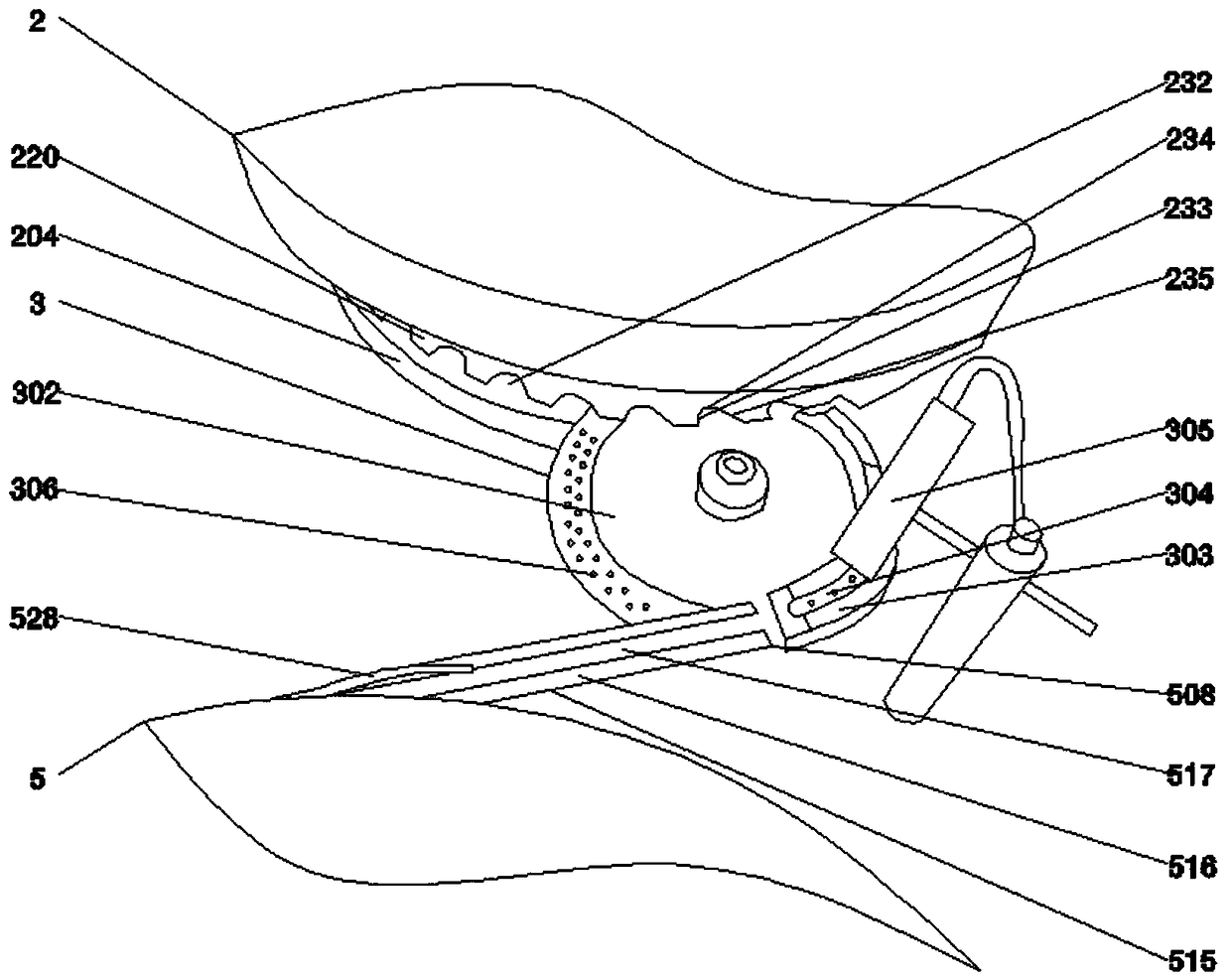

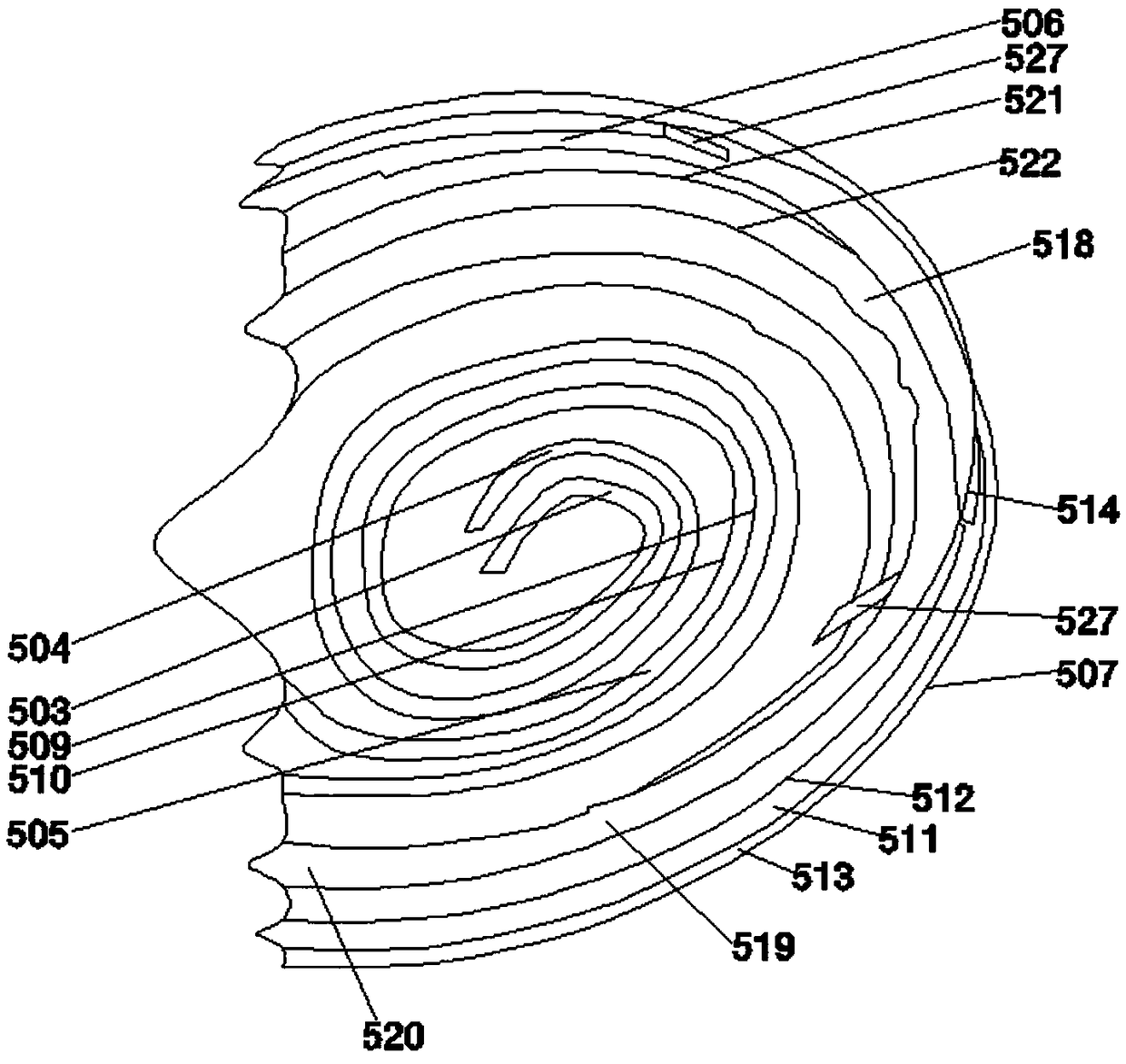

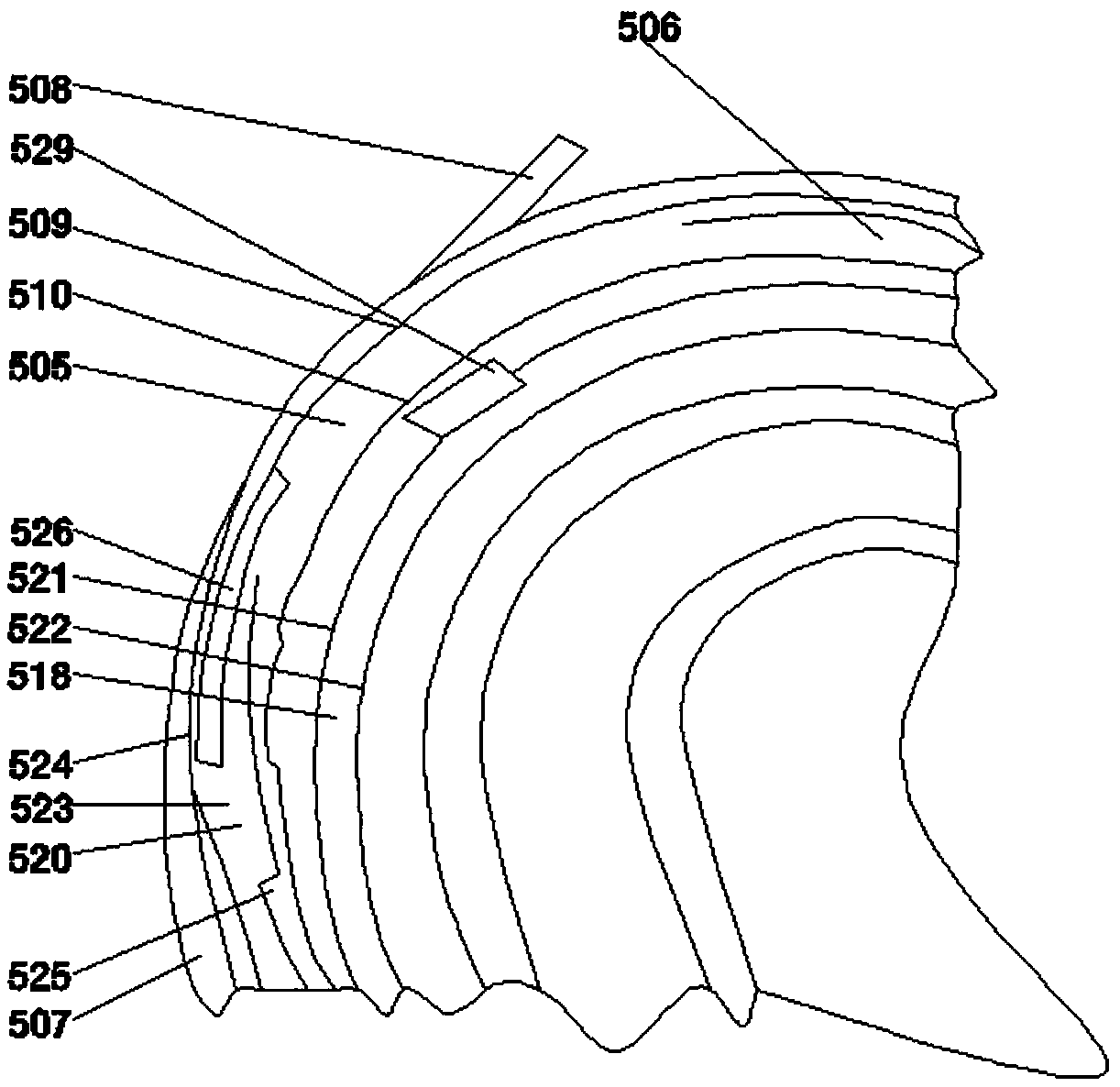

[0040] Such as figure 1 , figure 2 , image 3 and Figure 4 The rubber stopper conveying equipment in the shown oral liquid bottle cap assembly process includes a bracket 1, an adjustment mechanism 3 arranged on the bracket and a second feeding mechanism 5 in contact with the adjustment structure; the second feeding mechanism includes a second vibration Component 501 and the second conical material tray 502 arranged on the second vibrating assembly, the first spiral conveying track 503 and the second spiral conveying track 504 are arranged side by side on the second conical material tray, and the first spiral conveying track includes The first spiral conveying section 505, the second spiral conveying section 506, the third spiral conveying section 507 and the fourth linear conveying section 508 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com