Poker printing system with gravure printing and flexo printing combination

A printing system and playing card technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of not being able to adapt to multi-stations, time-consuming and laborious adjustments, and high production costs, so as to achieve easy adjustments, lower production costs, and less ink wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

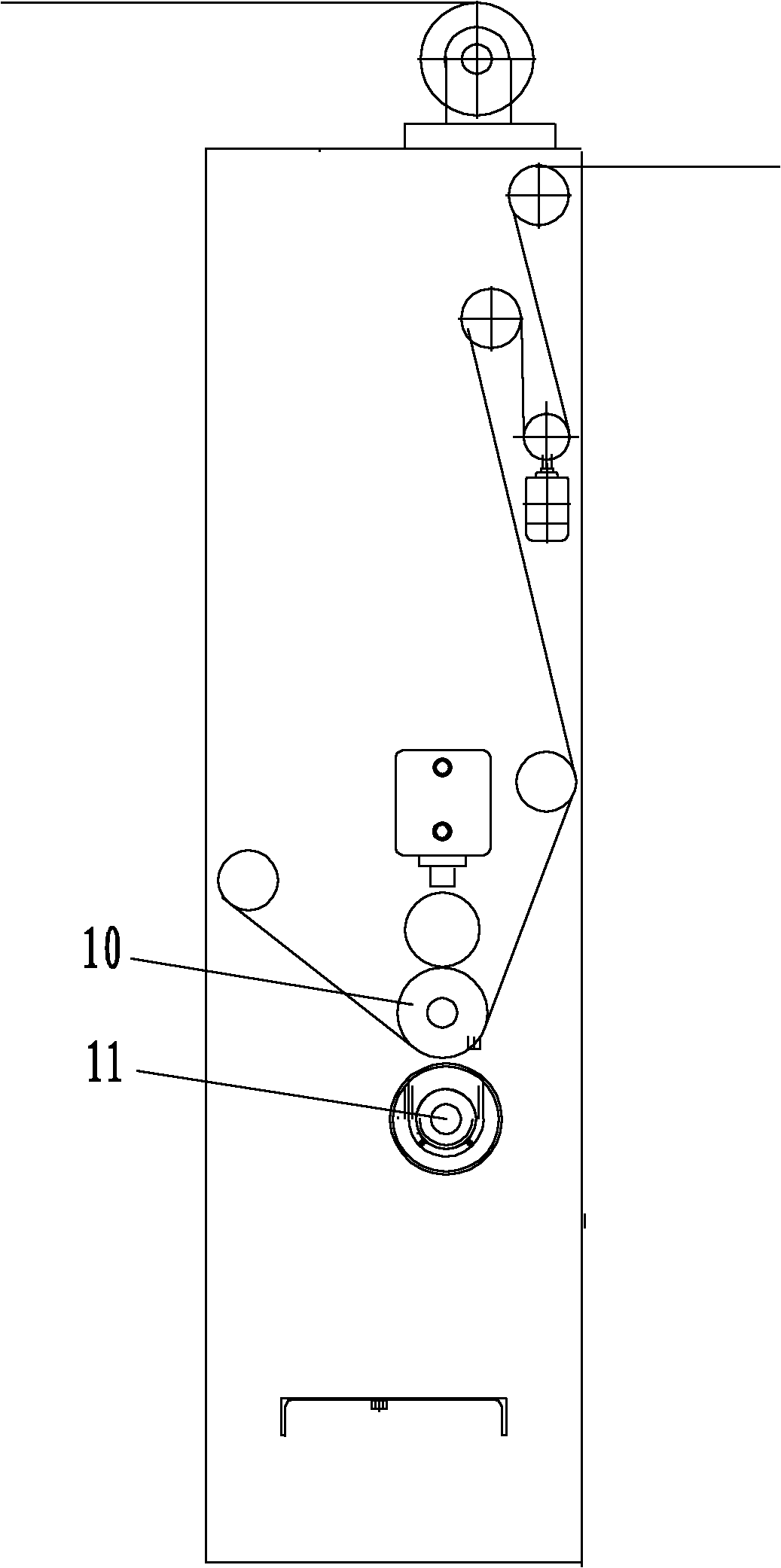

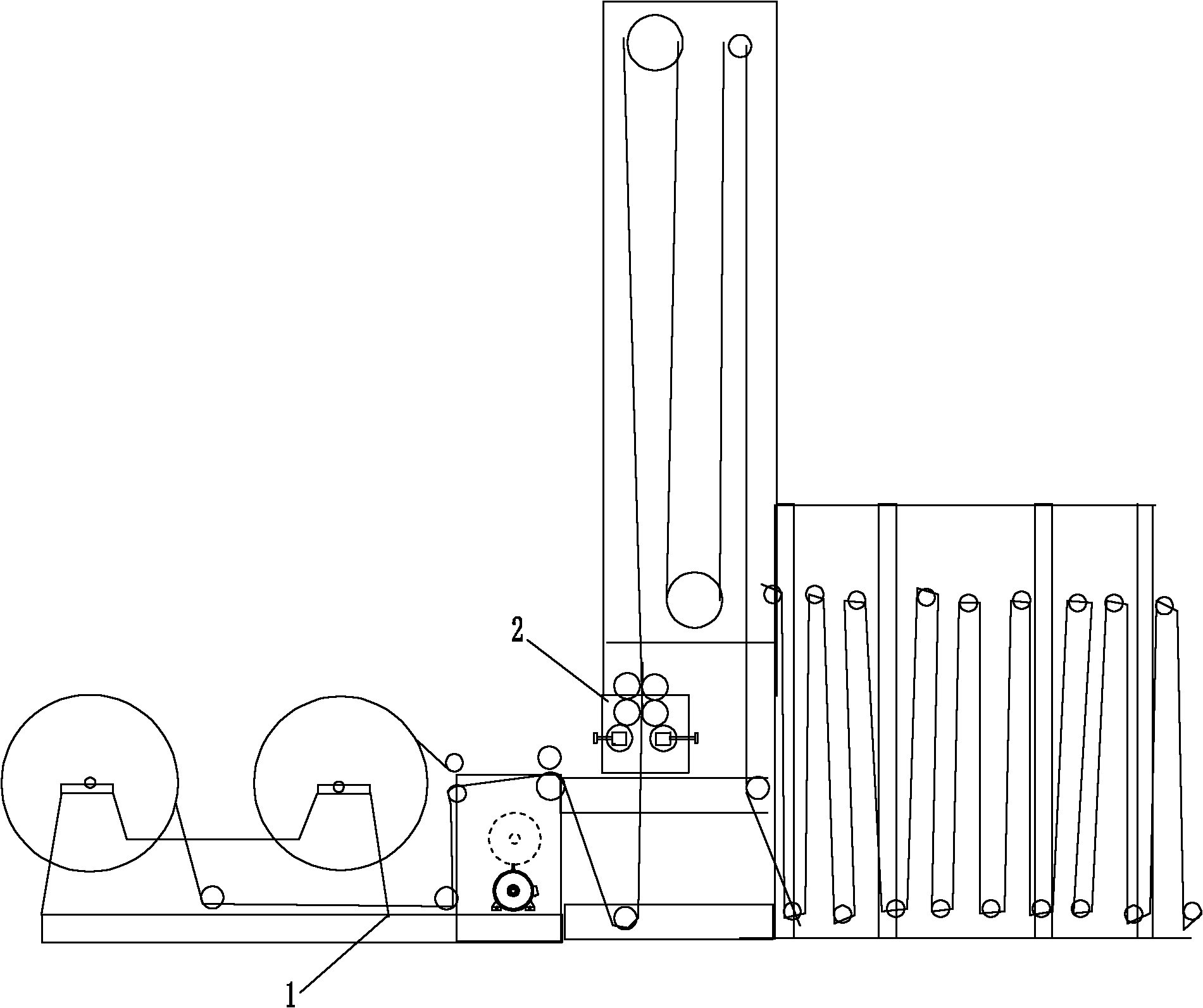

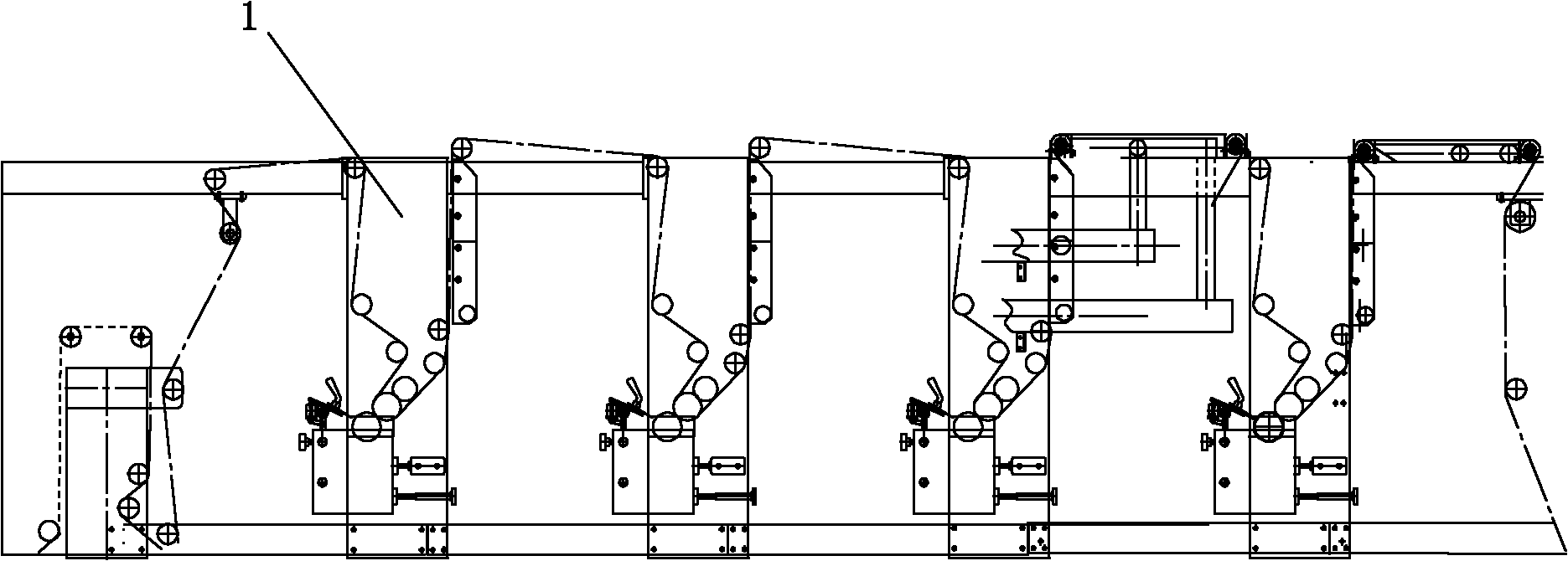

[0034] refer to Figure 2 to Figure 7 , a playing card printing system combined with gravure and flexo printing, comprising a frame 1, a powder coating part 2, a printing part, a glazing part 3, a drying part 4, a calendering part 5, Card cutting and receiving part 6, the printing part includes a gravure color group mechanism 7 for printing the back of the playing card and a flexo color group mechanism 8 for printing the front of the playing card, the flexo color group mechanism includes With the embossing rubber roller 10 of printing paper, described embossing rubber roller 10 is positioned at the frame below, and described embossing rubber roller 10 contacts with gravure printing plate roller 11, and described embossing rubber roller 10 and gravure printing plate roller 11, the station where the printed paper passes, the gravure printing plate roll 11 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com