Anti-blocking atomizer nozzle for preparing micro-fine metal powder and anti-blocking method thereof

An anti-clogging, metal powder technology, applied in the field of gas atomized melt to manufacture ultra-fine powder, can solve problems such as blockage of atomizer, achieve the effect of preventing blockage, simple and practical method, and solving blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

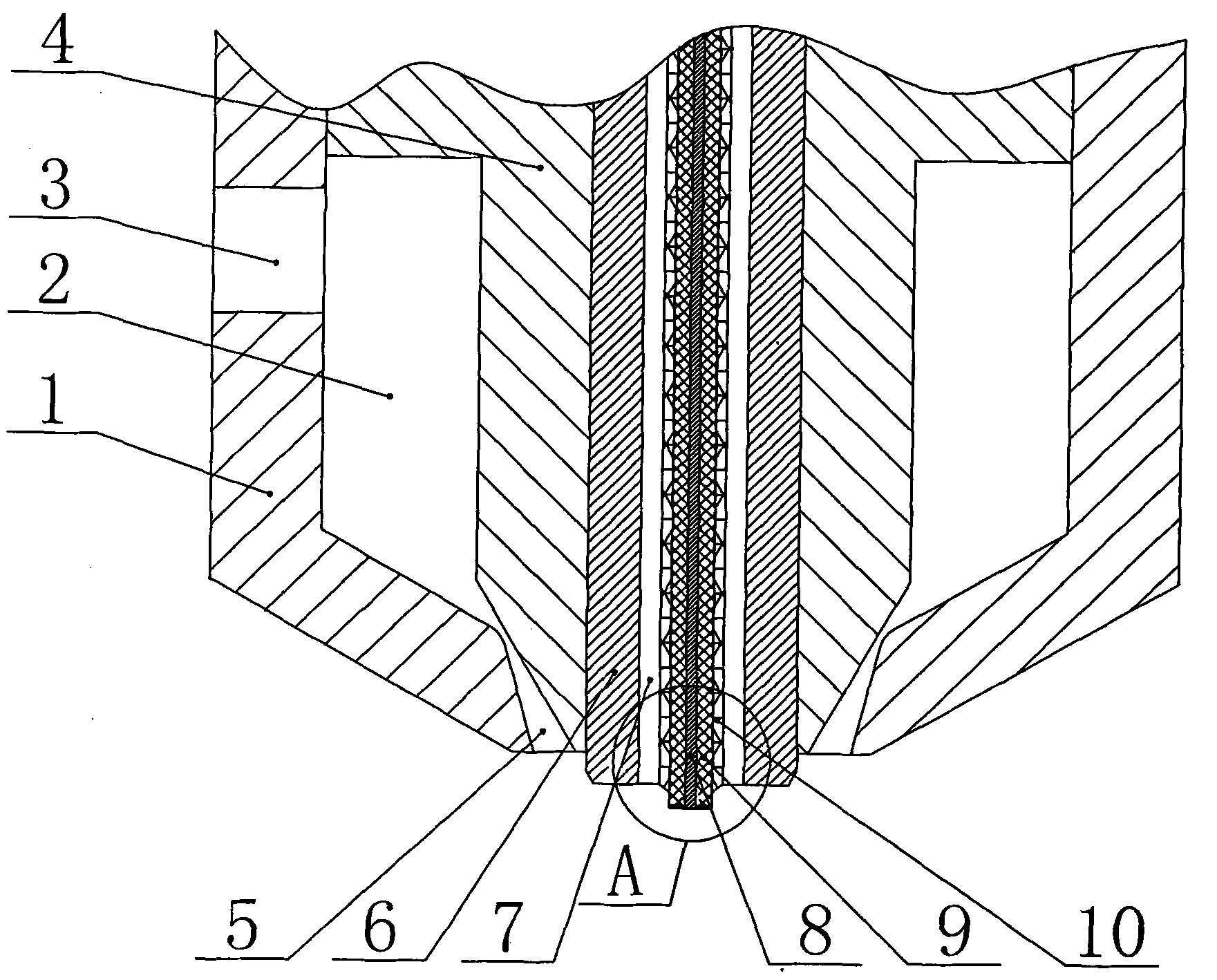

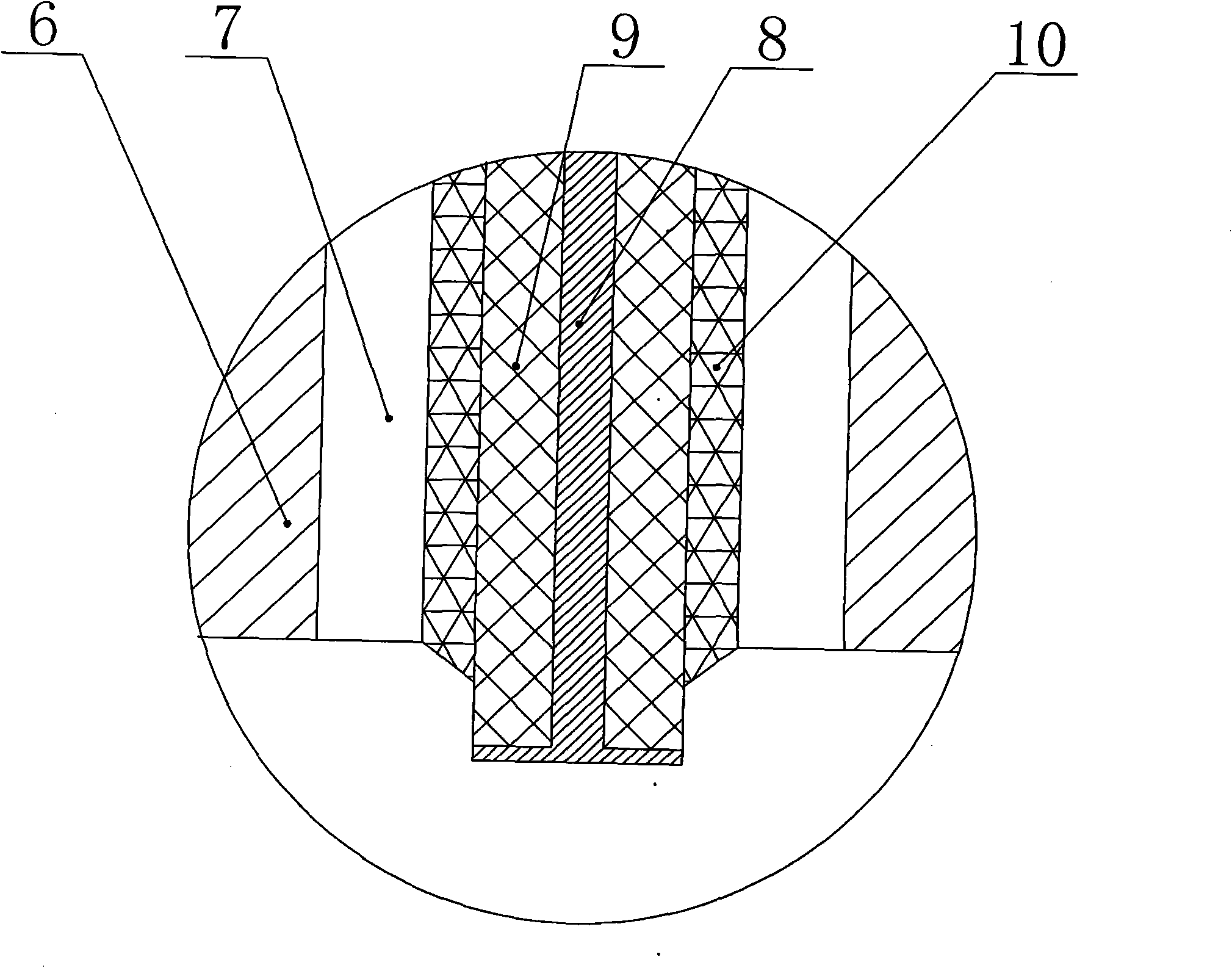

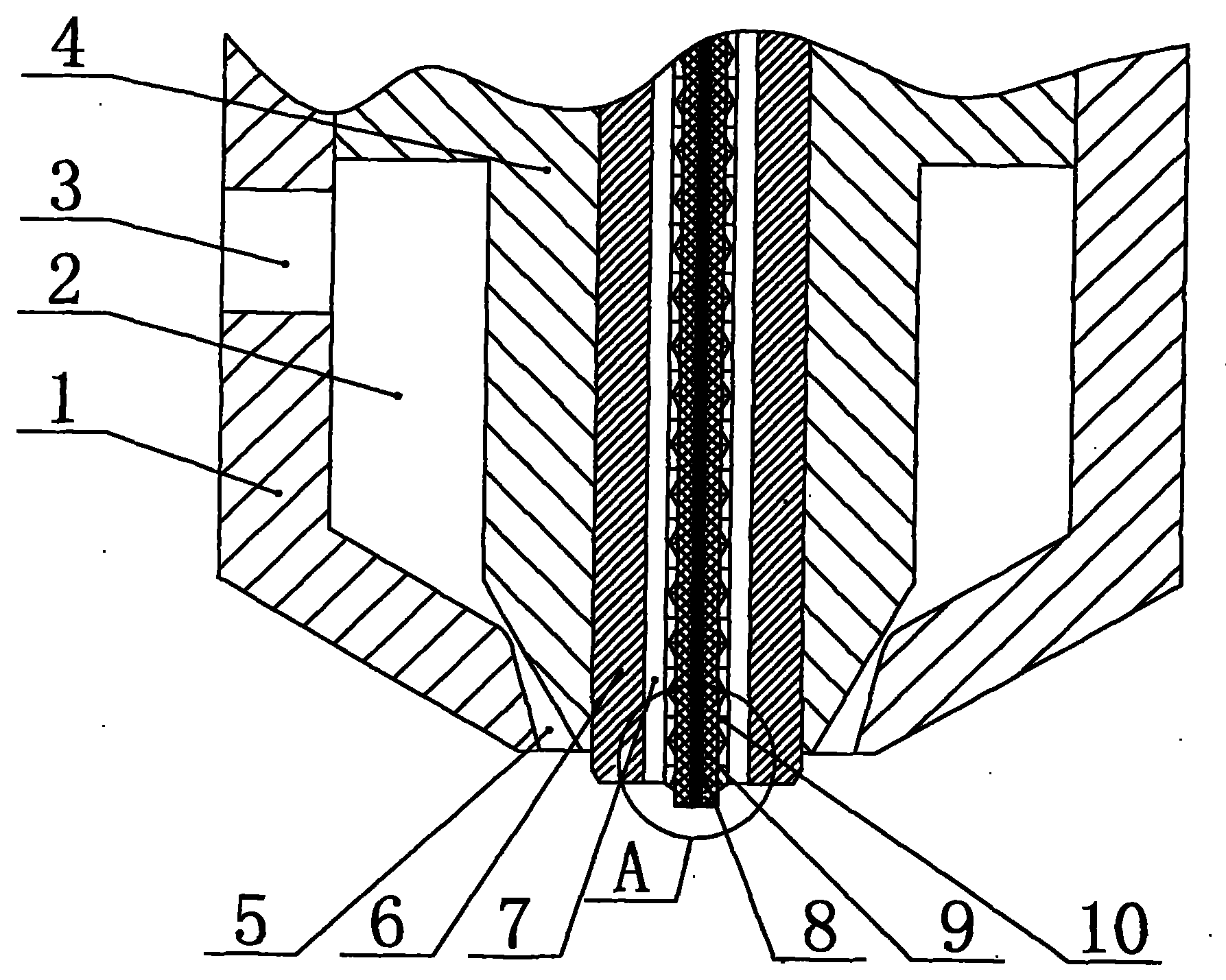

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] like figure 1 , figure 2 As shown, an anti-clogging atomizer nozzle for preparing fine metal powder, it includes a nozzle outer body 1, a nozzle inner body 4 and a guide tube 6, the nozzle inner body 4 adopts a high temperature resistant insulating material, and the guide tube 6 is set in the nozzle inner body 4, an air chamber 2 is arranged between the nozzle inner body 4 and the nozzle outer body 1, the air inlet hole 3 of the air chamber 2 is arranged on the nozzle outer body 1, the nozzle inner body 4 and the nozzle outer body 1. The nozzle structure 5 is formed at the nozzle of the guide tube 6. The guide tube 6 is connected to the negative pole of the power supply. The guide tube 6 is in the shape of a round tube. The guide tube 6 is made of high temperature resistant conductive ceramics, and a composite electrode rod is arranged in the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com