Transformer type sensor circuit system

A sensor circuit and transformer-type technology, applied in the field of sensors, can solve problems such as difficult implementation, poor sensitivity, and increased sensor volume, and achieve the effects of reducing the number of coil turns, excellent performance, and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

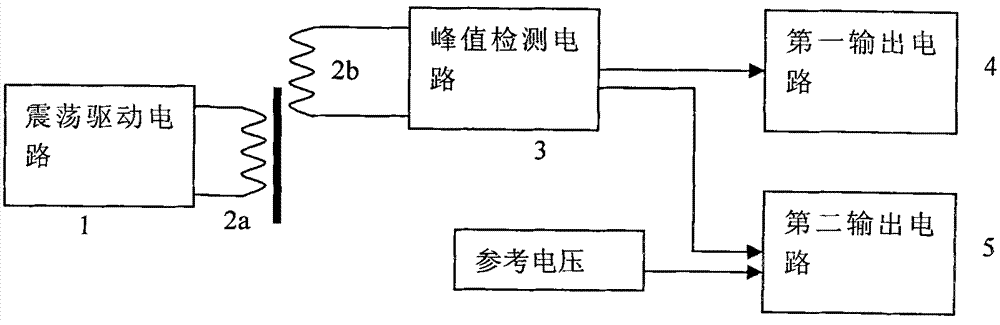

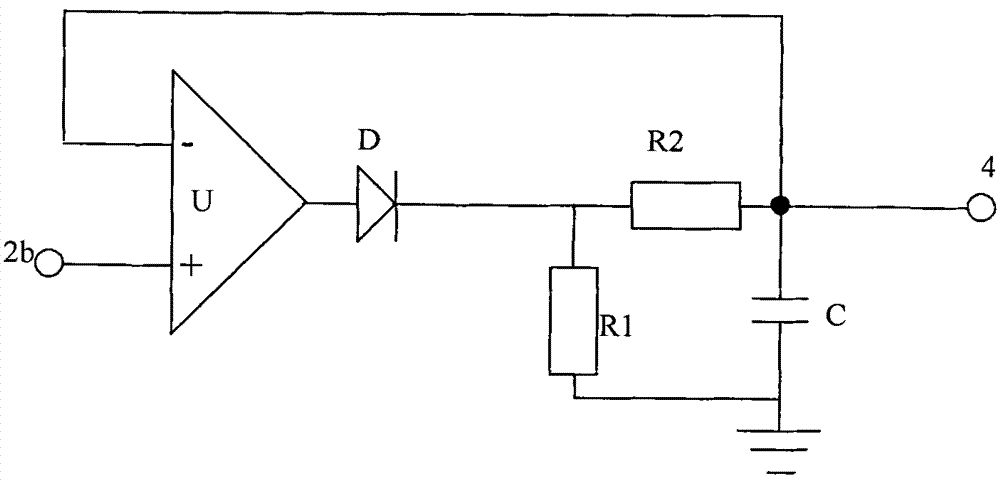

[0049] Such as figure 1 Shown: a transformer-type sensor circuit system, provided with an oscillating drive circuit 1, the output end of the oscillating drive circuit 1 is connected to the primary coil 2a of the transformer sensor, and the secondary coil 2b of the transformer sensor is connected to the processing circuit Above, the output end of the processing circuit is connected with the first output circuit 4 , and the processing circuit is a peak detection circuit 3 .

[0050] The oscillating drive circuit 1 is a pulse switch circuit, and the pulse switch circuit is a rectangular pulse drive circuit sent by a single-chip microcomputer, or an RC oscillating pulse drive circuit, or an LC oscillating pulse drive circuit, or is output after an alternating current coupling capacitor Peak pulse drive circuit.

[0051] In the known tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com