Silicon-free steel sheet motor

A silicon steel sheet and coil layer technology is applied in the field of silicon-free steel sheet motors, which can solve the problems of many coils and magnetic blocks, low power conversion efficiency, low utilization rate, etc., and achieves thin stator thickness, reduced usage, and high magnetic permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

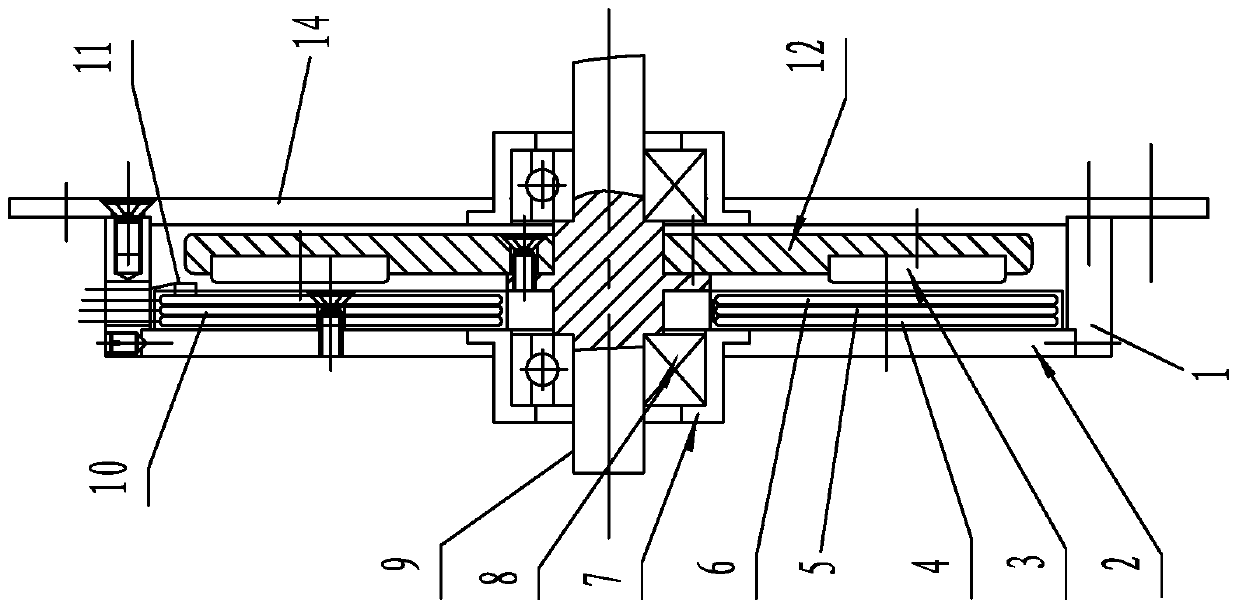

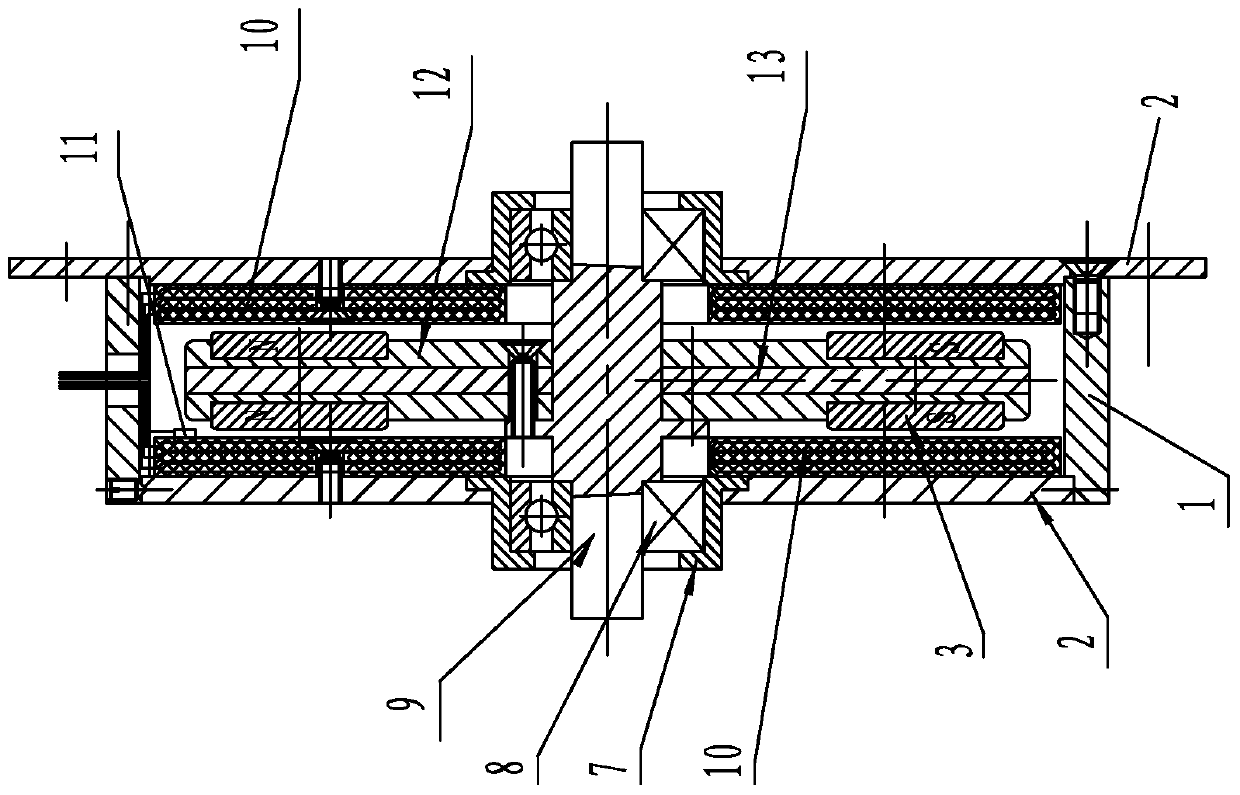

[0027] Such as Figure 1-10 As shown, the silicon-free steel sheet motor of the present invention includes an annular casing 1, a stator 10 coaxially arranged in the casing, a rotor 12, a pair of bearing housings 7 matched with the rotating shaft 9 bearings of the rotor 12, and each bearing The seat 7 is fixed in the annular casing 1 through a corresponding cover plate, and each coil layer on the stator includes 18, 21, 24 or 27 sector-shaped planar coils 15 .

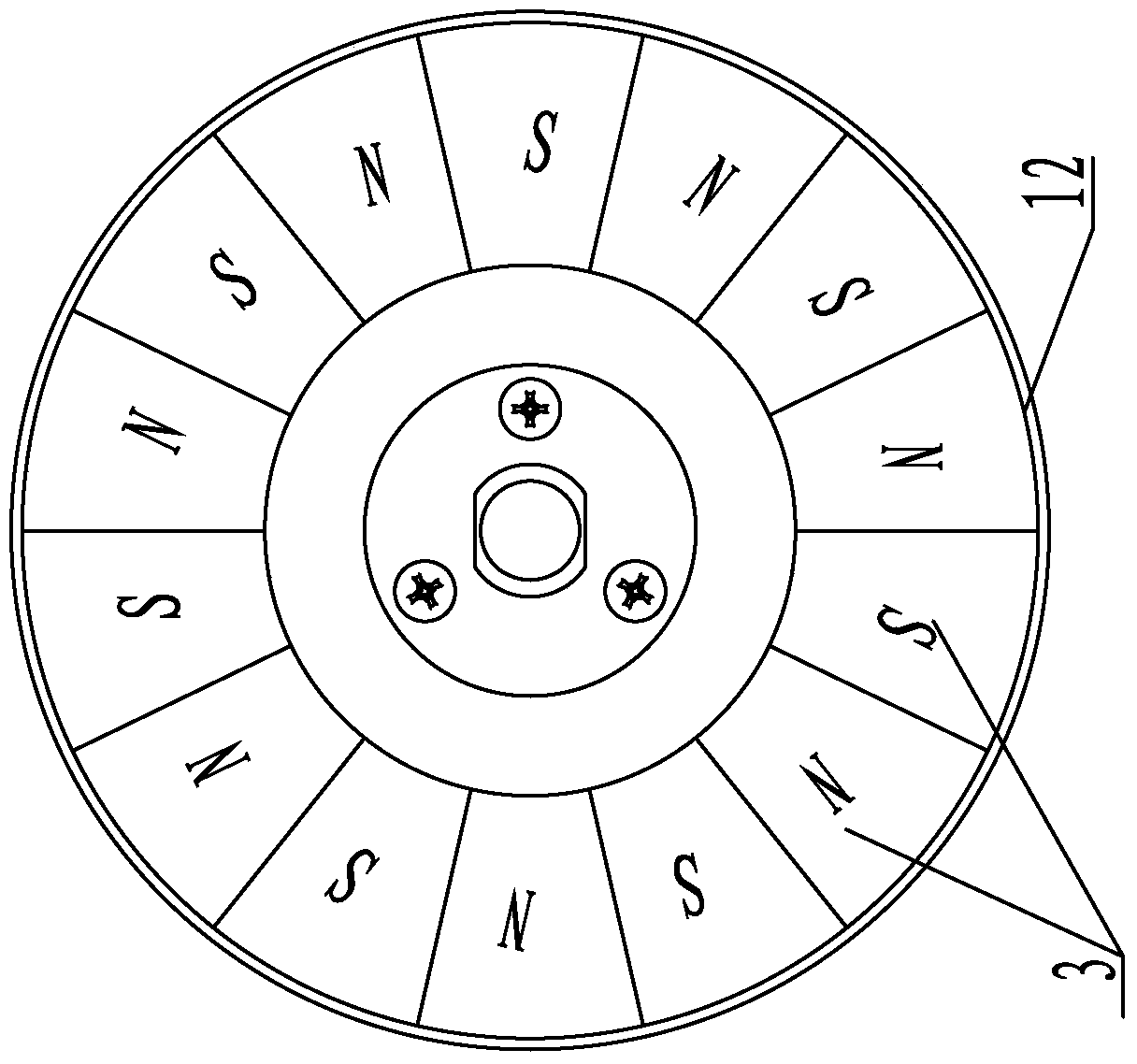

[0028] There are 2-20 permanent magnet blocks 3 on the rotor 12, distributed symmetrically with the center of the circle.

[0029] The coil layers are integrated by hot pressing of plastic composite materials, and the plastic contains 20wt% or 10wt% or 30wt% or 40wt% or 50wt% of magnetic powder. The magnetic powder is one or more of iron oxide magnetic powder, cobalt-iron oxide magnetic powder and chromium dioxide magnetic powder.

[0030] The outer side of the stator 10 is provided with a magnetically permeable cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com