Method for producing large-size thin ceramic bricks by microwave and hot air composite drying

A technology of composite drying and production methods, applied in the application, household appliances, other household appliances and other directions, can solve the problems of cracking and deformation of the heating blank, and achieve the effects of constant thermal stress, good shaping quality and simple drying method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Test site: Guangdong Mona Lisa Ceramics Co., Ltd. Run through the test line. Use microwave and hot air to dry ceramic tile body.

[0032] The production method and process are:

[0033] The thin ceramic tile body with a moisture content of 16% to 18% first enters the microwave drying room, the drying temperature is 50°C, and the drying time is about 20 minutes. The temperature is 105°C, the drying time is about 40min, and the pressure is 22Pa.

Embodiment 2

[0035] The production method and process are:

[0036] Thin ceramic tiles with a moisture content of 16% to 18% first enter the microwave drying room, the drying temperature is 80°C, and the drying time is about 17 minutes, and the moisture in the ceramic tiles is dried to around 8% moisture content; directly enter the hot air drying room , the hot air temperature is 120°C, the drying time is about 35min, and the pressure is 28Pa.

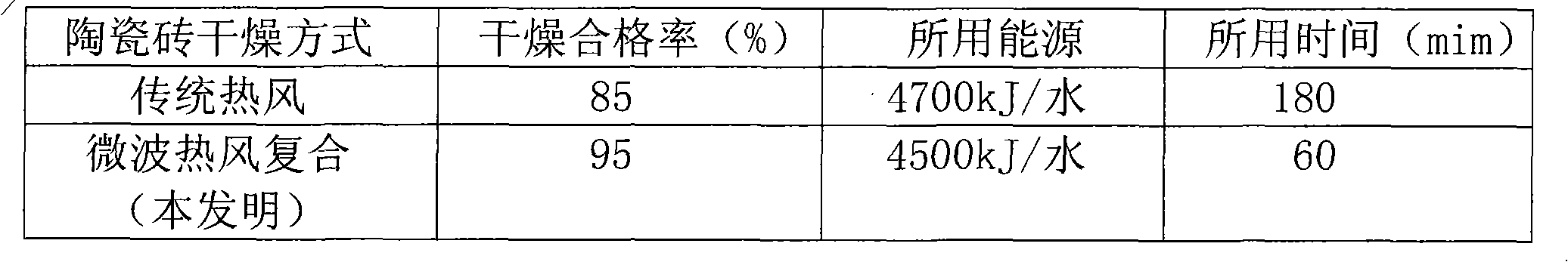

[0037] The experimental statistical results are shown in the table below:

[0038] Experimental results:

[0039]

[0040] From the above experimental statistical table, compared with the traditional ceramic tile body dehydration and drying method, the qualified rate of the ceramic tile body is significantly improved in the present invention. After adopting the microwave hot air composite new technology, the qualified rate of the ceramic tile body drying can reach 95%, and the energy-saving effect very obvious. The time taken to produce the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com