Method for forming welding convex block

A technology for welding bumps and metal layers under bumps, which is applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve problems affecting chip performance and quality, chip short circuit, etc., to improve performance and quality, The effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the technical content of the present invention, specific embodiments are given and described in conjunction with the accompanying drawings as follows.

[0034] The present invention provides a method for forming welding bumps, which is used to solve the phenomenon of infiltration and plating in the prior art and improve the performance and quality of chips.

[0035] Please refer to Figure 8 , Figure 8 Shown is a flow chart of a method for forming solder bumps according to a preferred embodiment of the present invention. The method for forming solder bumps proposed by the present invention includes the following steps:

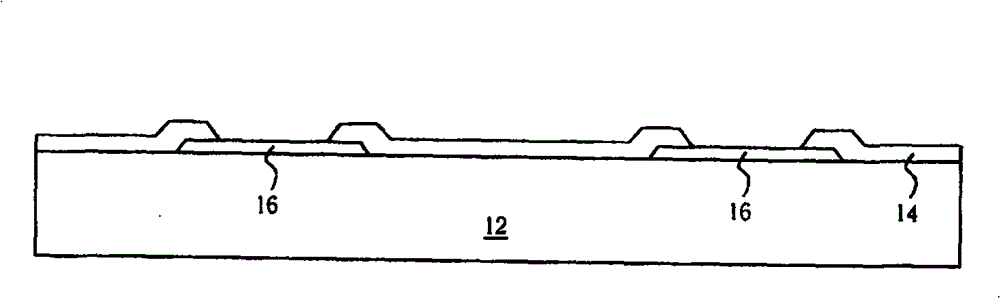

[0036] Step S100: providing a substrate, and sputtering a metal layer under the bump on the surface of the substrate;

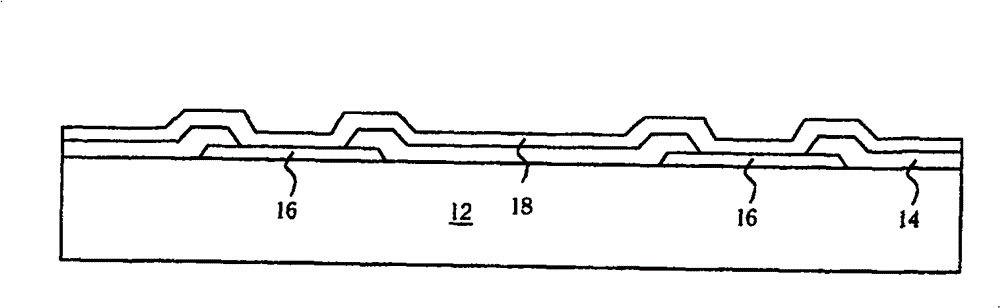

[0037] Step S200: etching the metal layer under the bump with a metal layer etchant;

[0038] Step S300: cleaning and drying the metal layer under the bump;

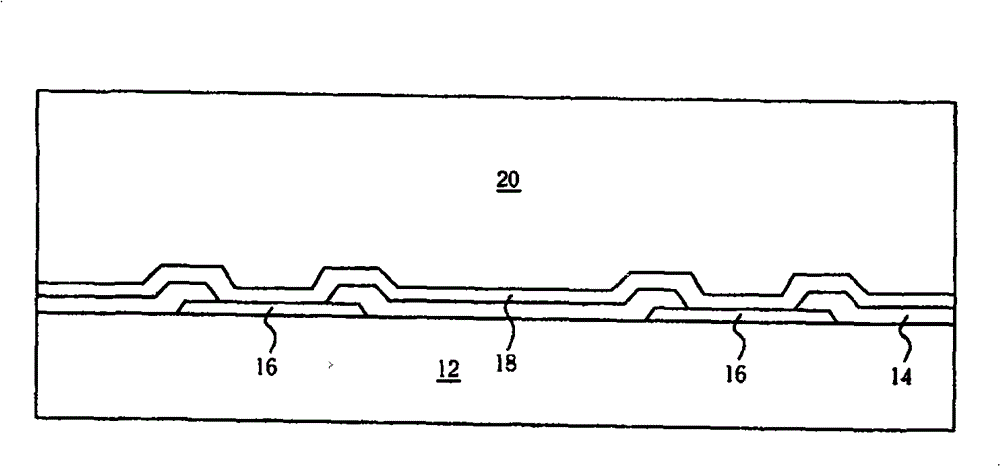

[0039] Step S400: forming a dry film pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com