Six-reel steel band armouring machine

An armoring machine and steel tape technology, applied in the field of steel tape armoring, can solve the problems of complex design structure, high manufacturing difficulty and high manufacturing cost, and achieve the effects of advanced control technology, reasonable mechanical structure and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

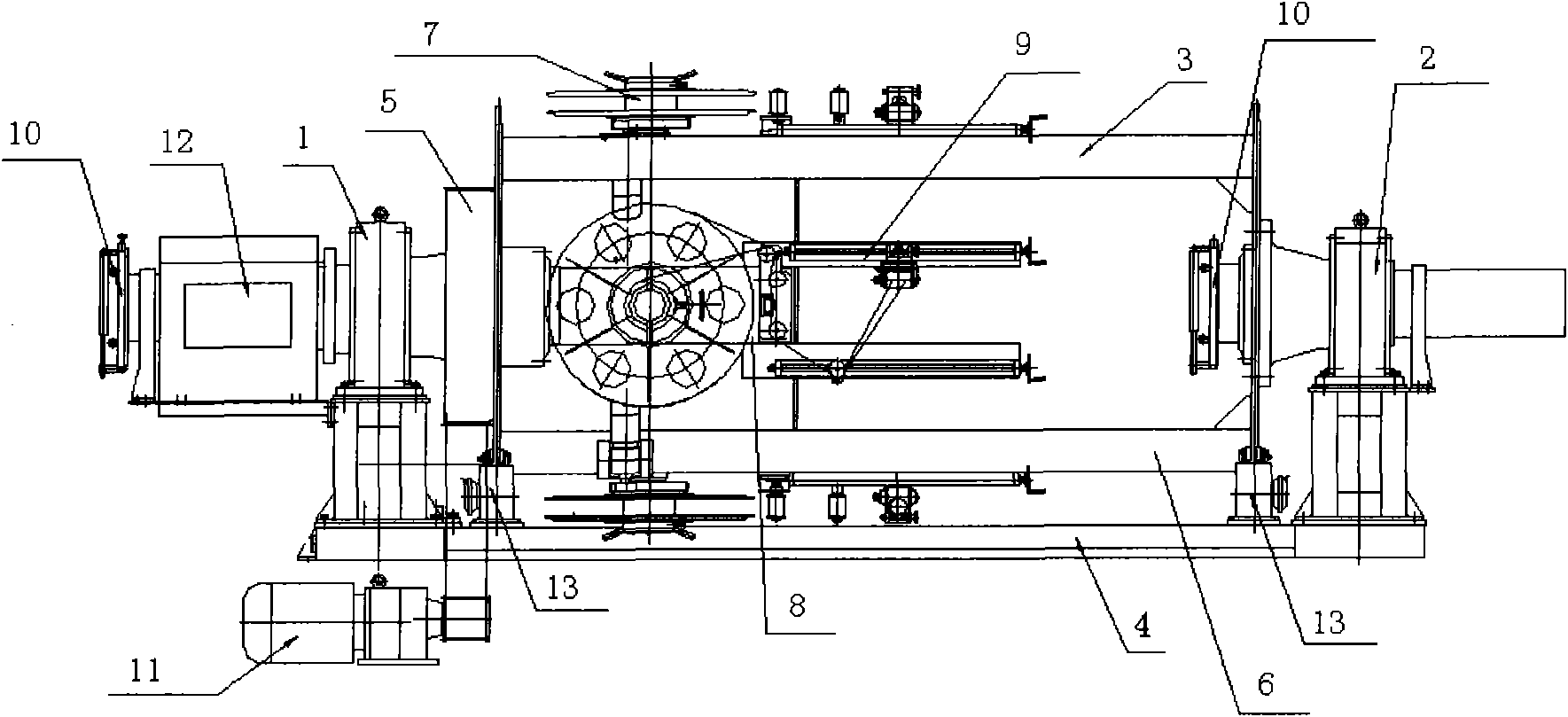

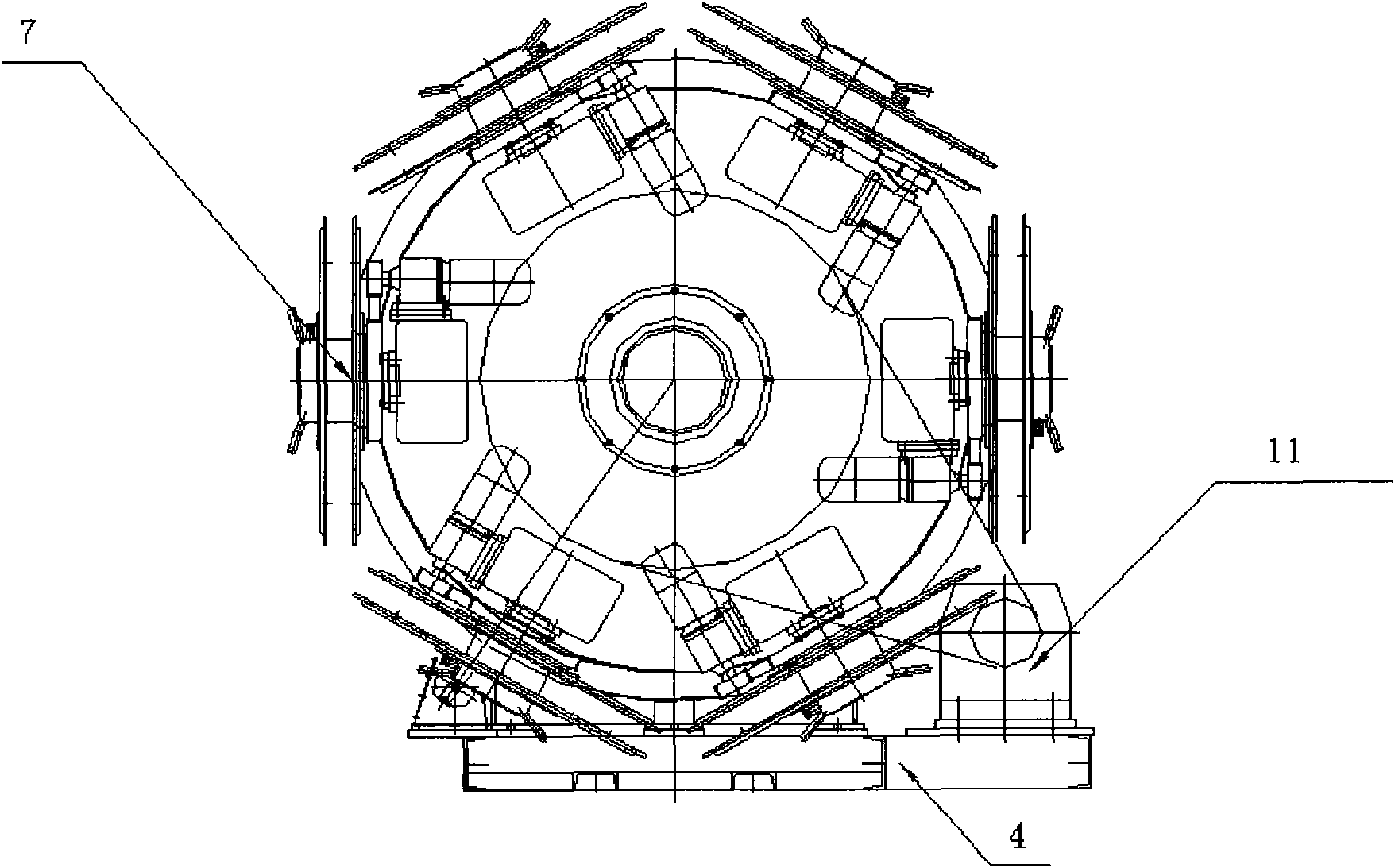

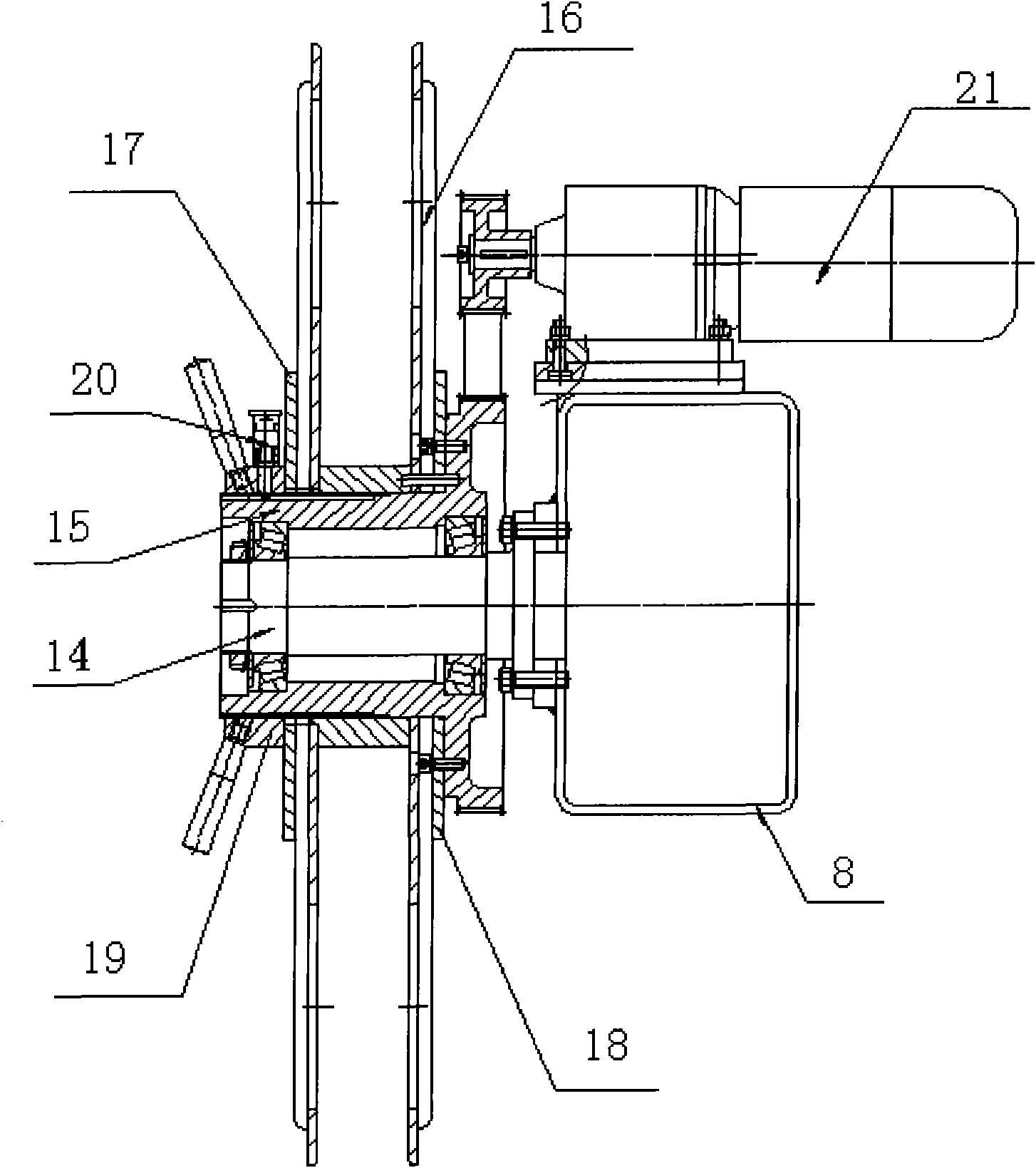

[0012] Six-disc steel tape armoring machine, including front and rear support frames 1, 2, rotating body 3, and installation base plate 4: the upper end of the installation base plate 4 is fixedly installed with front and rear support frames 1, 2, conductive device 12, brake device 13, and motor drive device 11, The upper ends of the front and rear support frames 1 and 2 are equipped with a rotating body 3, and the rotating body 3 is provided with six steel tape reels and an active tape release device 7, a belt guide device 9, and a center adjustable protective tube; the front and rear support frames 1, 2 A hollow flange shaft 5 is set on a large bearing seat, and the hollow flange shafts 5 on both sides are flange-connected with the rotating body 3 to support the rotation of the twisted body; the rotating body 3 is a cylindrical structure, and the rotating body 3 has two The end is a flange 5, and the middle is connected by two rectangular steel beams 6 to form a rigid rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com