Production method of metal framework composite hose

A composite hose and metal skeleton technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as damage, elongated pipe body, difficult to pull out, etc., and achieve the effect of convenient use and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

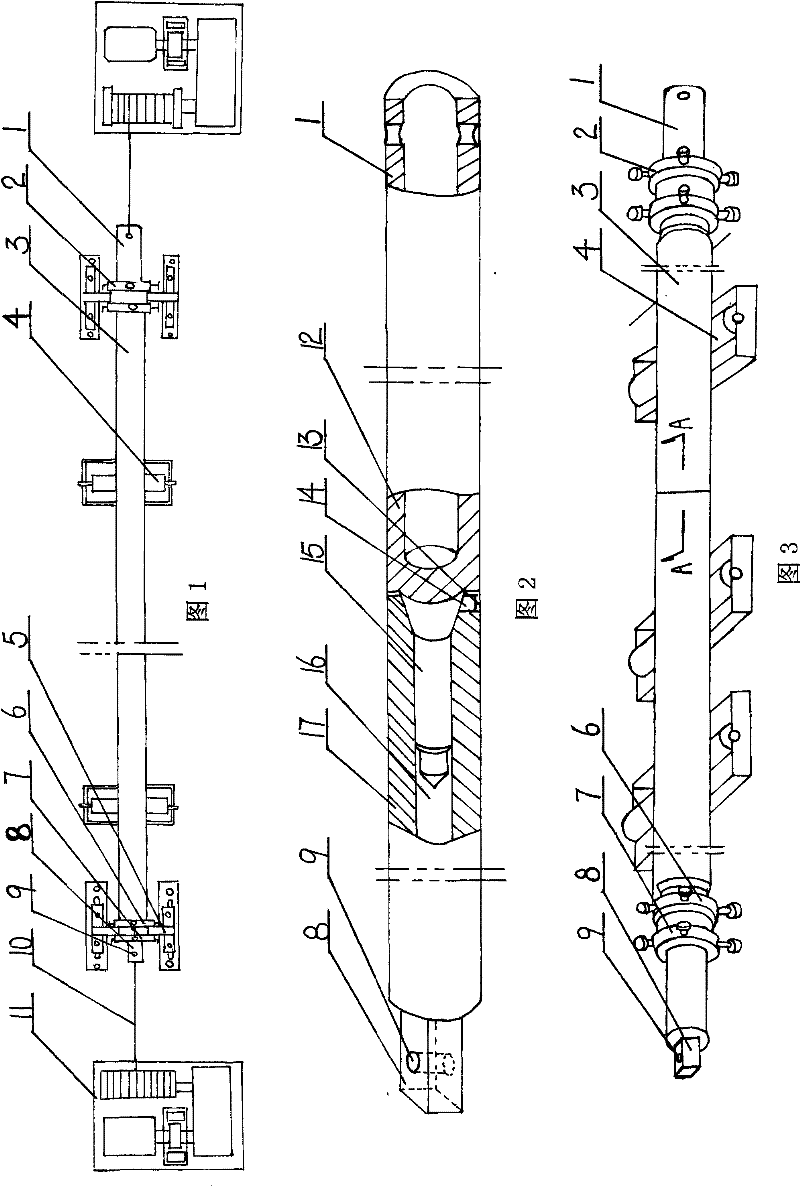

[0020] Embodiment 1: process the 15-meter-long metal skeleton composite flexible pipe 3, adopt a pipe core 1, and its steps are as follows:

[0021] The first step is to arrange the double chain rings 2 on both sides of the die 1 respectively;

[0022] In the second step, lubricating oil is applied outside the tube core 1, and then the padding 18 is wound outside the lubricating oil (the padding 18 can be plastic);

[0023] The 3rd step, wrap steel wire 19, plastic cloth 20, steel wire 19 to form metal frame composite flexible pipe 3 (this is conventional technology, can adopt different steel wire 19, plastic cloth 20 according to user's needs) successively outside pad cloth 18;

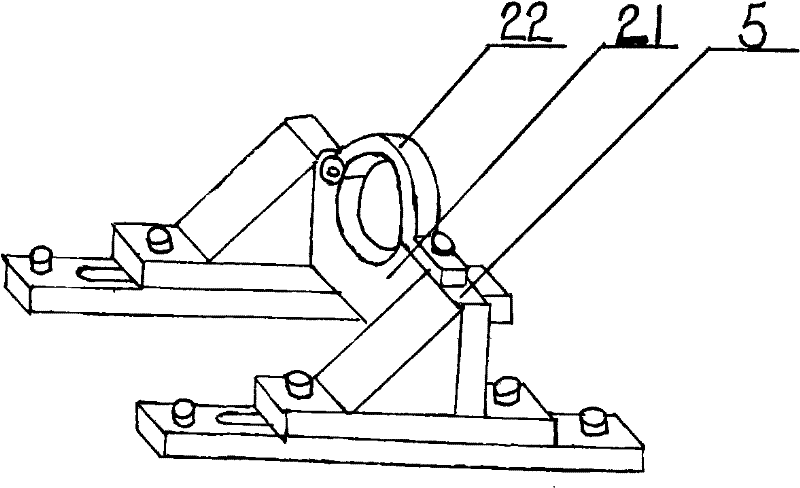

[0024] The fourth step is to place the metal skeleton composite hose 3 on the support roller 4 between the winches 11, loosen the tube core positioning ring 7 of the double chain 2 respectively, and move the metal through the fixed ring 21 and the movable ring 22 of the positioning frame 5. The fram...

Embodiment 2

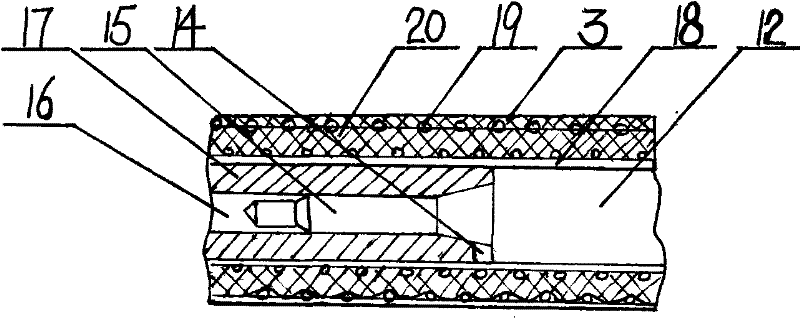

[0025] Embodiment 2: process the 30-meter-long metal skeleton composite hose 3, adopt two tube cores 1, i.e. the left tube core 17, the right tube core 12, and its steps are as follows:

[0026] The first step, first, combine the inner hole 16 of the left die 17 with the positioning rod 15 of the right die 12, and combine the shifting block 14 of the right die 12 with the groove 13 of the left die 17, that is, the left die 17 1. The right tube core 12 is combined to form a tube core 1; the double chain rings 2 are respectively arranged on both sides of the tube core 1;

[0027] In the second step, lubricating oil is applied outside the tube core 1, and then the padding 18 is wound outside the lubricating oil (the padding 18 can be plastic);

[0028] The third step, fix the positioning block 8 on the end of the left tube core 17 on the center hole of the machine tool head, fix the end of the right tube core 12 on the top of the machine tool; 1. Wrap steel wire 19, plastic clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com