Modularized roll surface for moving article

A modular, flat technology, applied in the direction of rollers, rollers, conveyor objects, etc., which can solve problems such as surface damage, low total resistance, and object advancement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

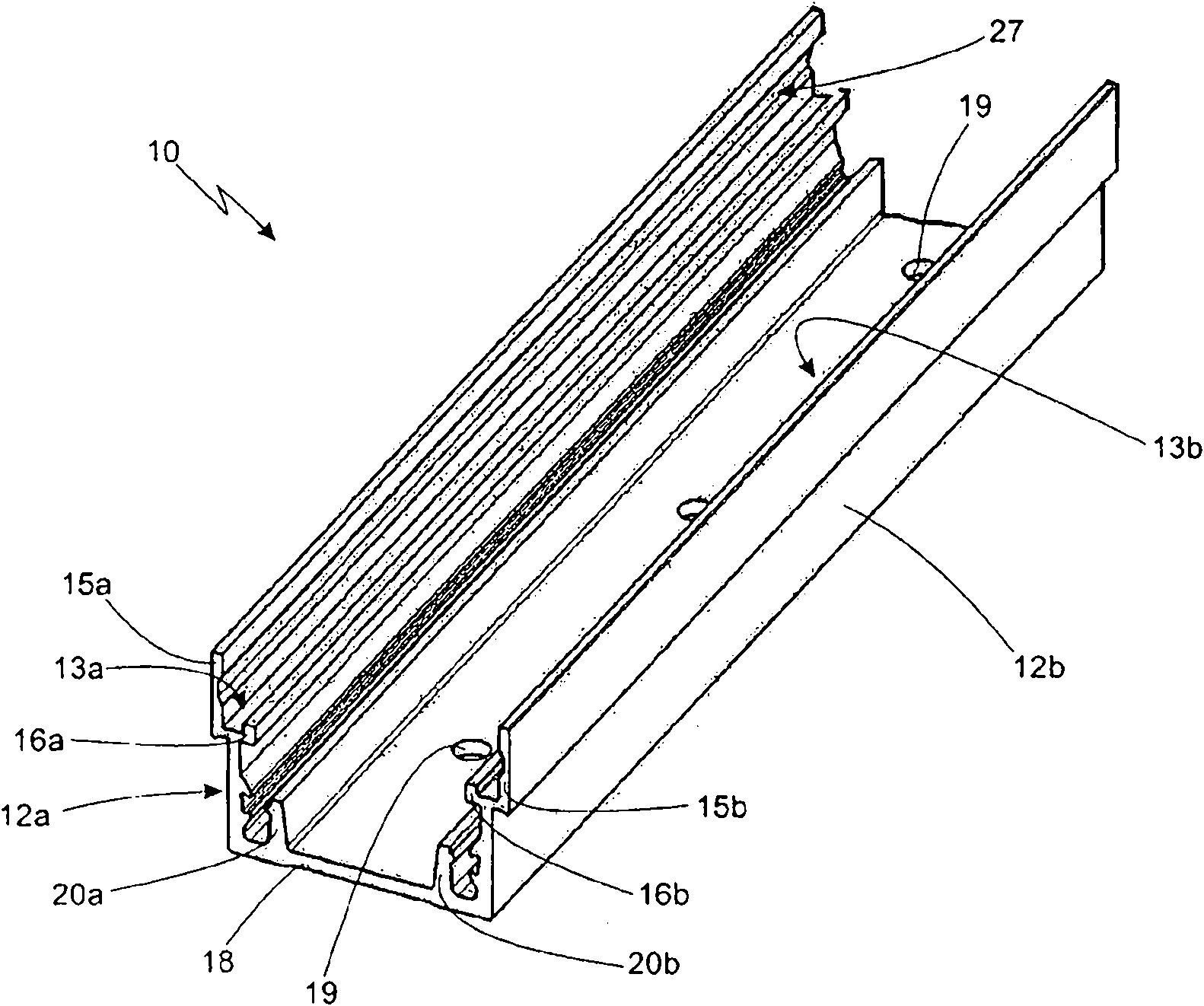

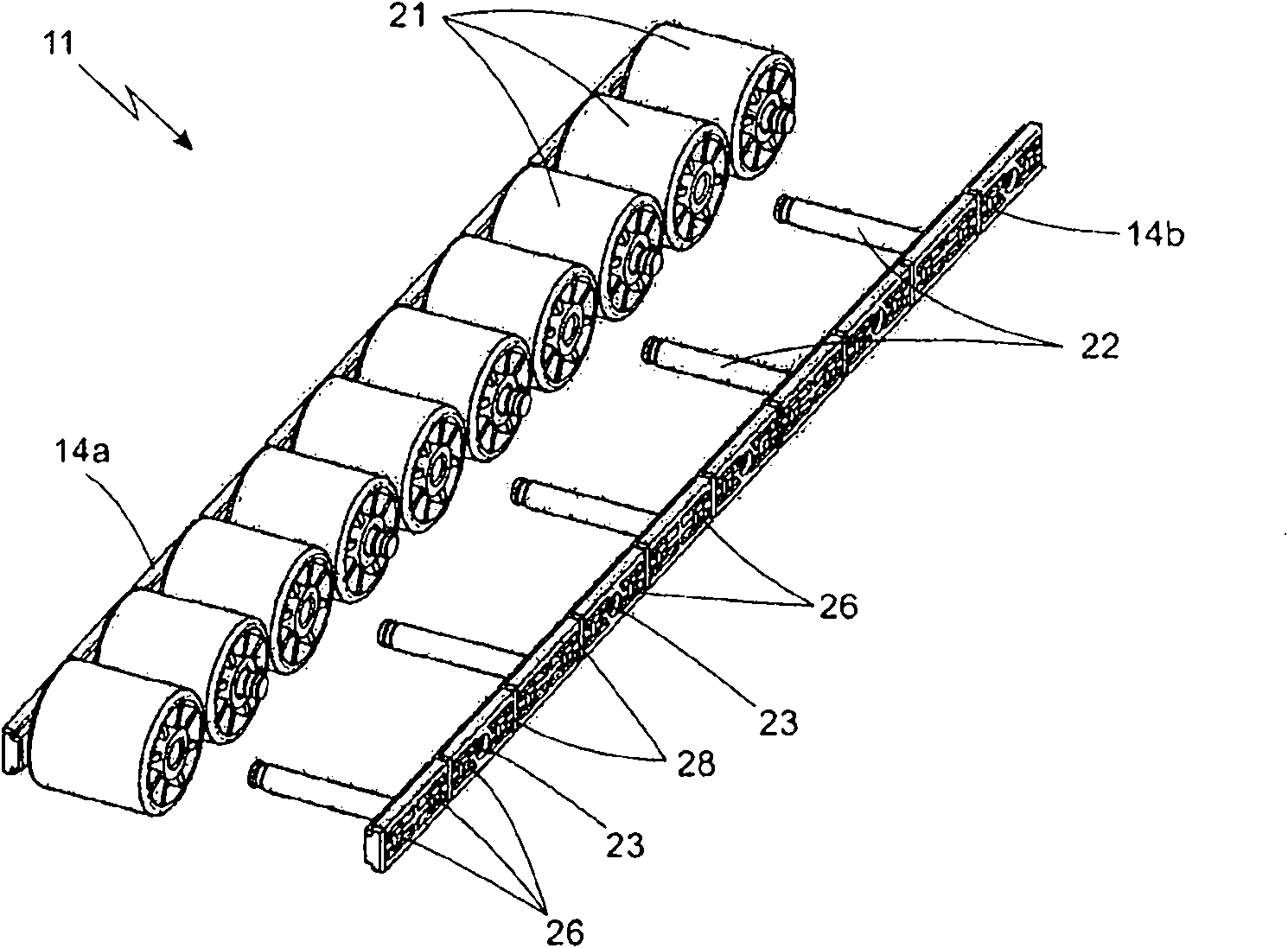

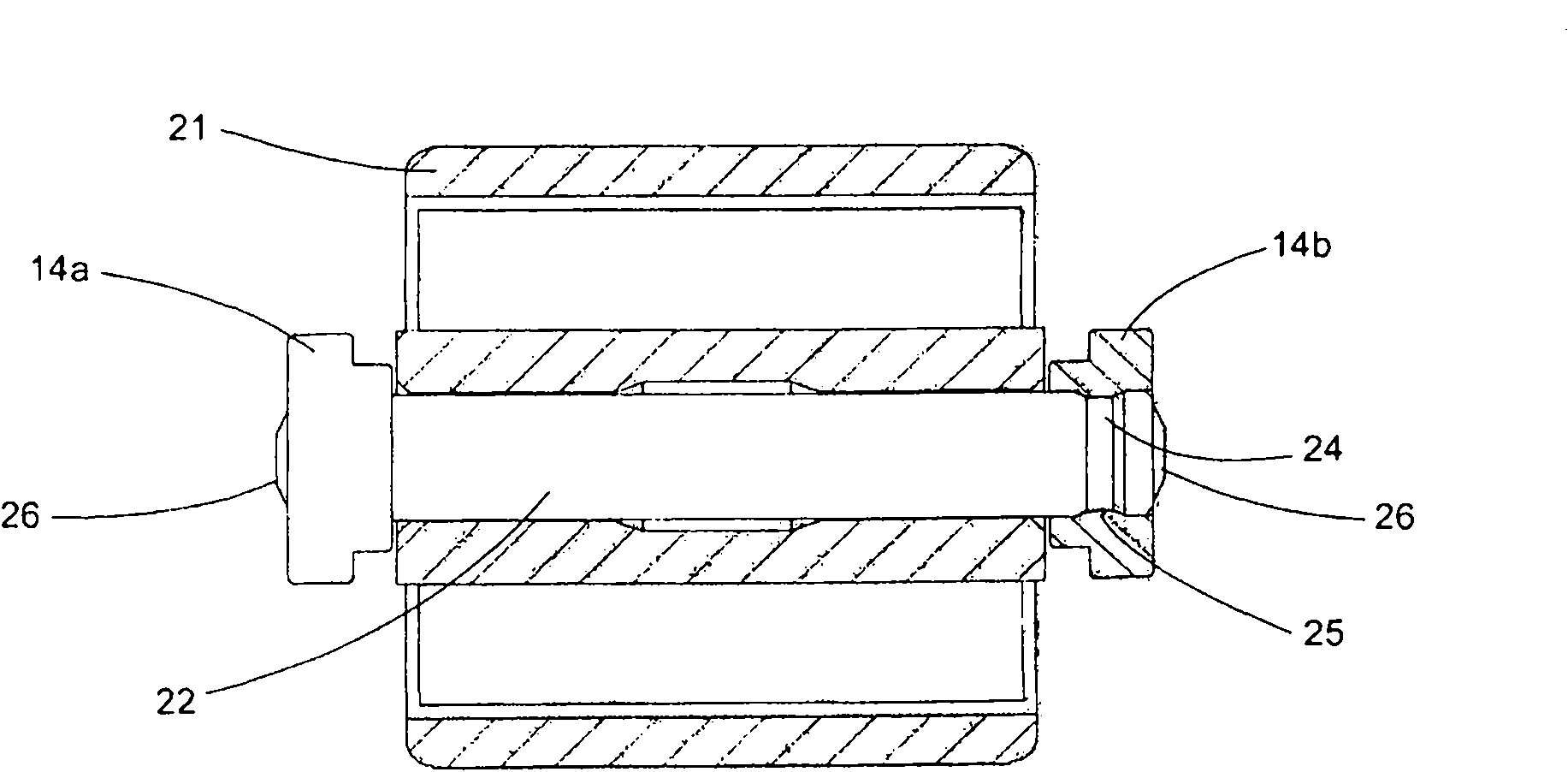

[0026] refer to figure 1 , 10 denotes a support frame for a roller plane for moving light items along a conveyor line, the base of a processing machine, a gravity-operated warehouse, or other similar applications, where, in particular, the conveyed items have features that require protection from scratches or Dented exterior surface. The frame, preferably manufactured from extruded aluminum profiles, is substantially U-shaped and is intended to receive e.g. Figure 5 At least one roller bracket 11 is shown in. To this end, the frame 10 comprises two sides 12a, 12b in which longitudinal seats 13a, 13b for receiving the outer longitudinal bars 14a, 14b of the support 11 are formed. The longitudinal base 13a, 13b comprises an outer wall 15a, 15b and an inner protrusion 16a, 16b parallel to the outer wall and at a distance therefrom equal to Figure 4 The width of the longitudinal bars 14a, 14b of the bracket 11 can be seen in . The inner protrusions 16a, 16b allow the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com