Dicing cover applied to dicing cutter

A granulator and granulation technology, which is applied in the direction of coating, etc., can solve the problems that it is difficult to observe the granulation of the machine head, the granulation and the connection device, and the inconvenience of operation and maintenance of the operator. Achieve the effects of simple structure, convenient maintenance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

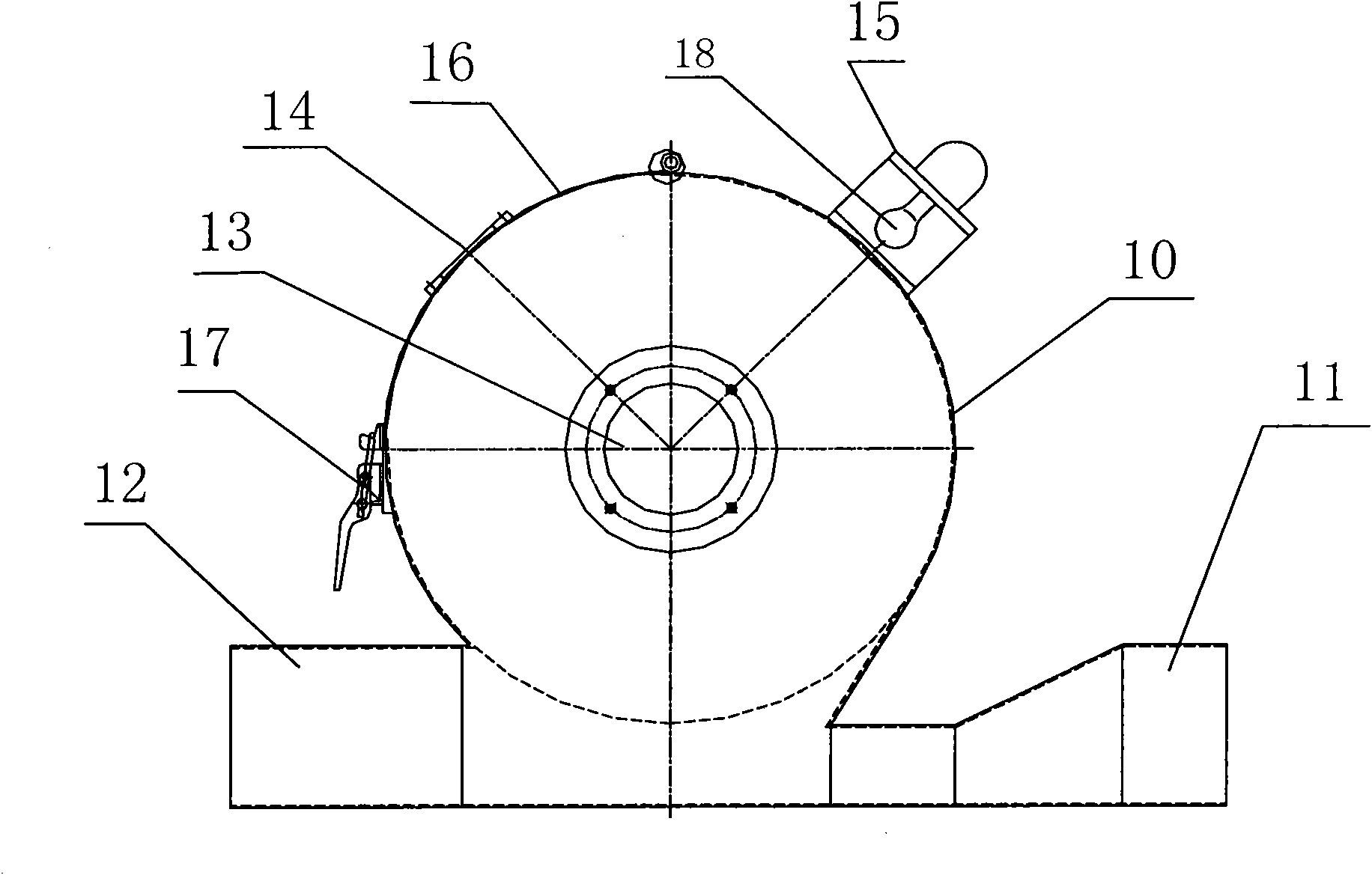

[0014] see figure 1 , a kind of pelletizing cover applied to the pelletizing machine of the present invention, it comprises a circular cover body 10; What this cover body 10 adopts is that stainless steel material is welded to form, and in the manufacturing process, the plate selected should be flat, No distortion, and the weld bead should be flat without obvious steps, making it beautiful and durable. An air inlet duct 11 and an air outlet duct 12 are welded at the bottom of the cover body 10, and the air inlet duct 11 and the air outlet duct 12 are arranged on the same straight line, and their opening directions are opposite, which is an opposite arrangement structure; A blower can be installed at the mouth of the pipe to air-dry and send the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com