Charging roll and method of producing the same

A charging roller and conductive technology, applied in the field of charging roller, can solve the problems of sticking to the photosensitive drum and the peeling of the surface of the charging roller, and achieve the effects of suppressing pollution, preventing surface peeling, and suppressing image defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

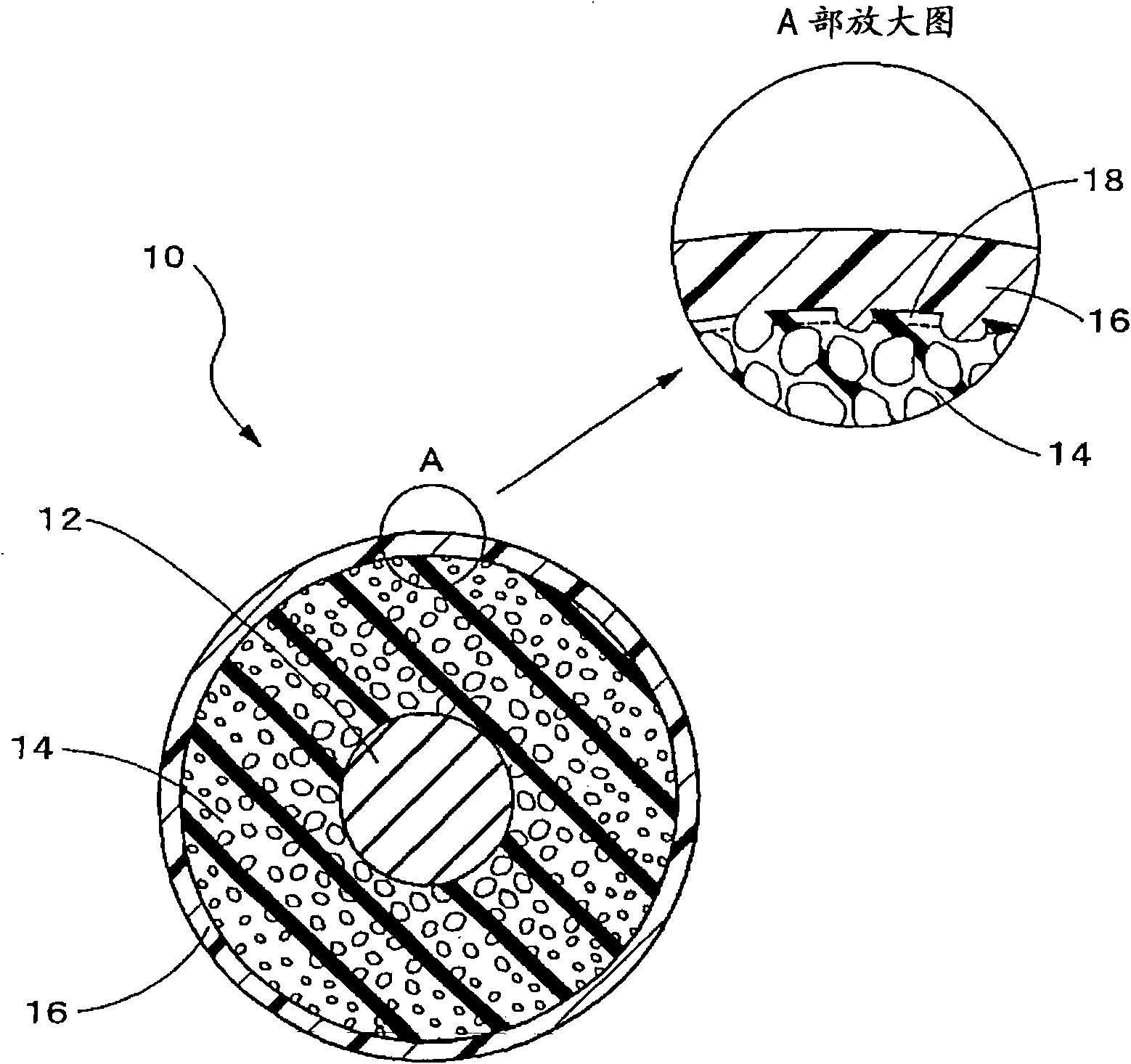

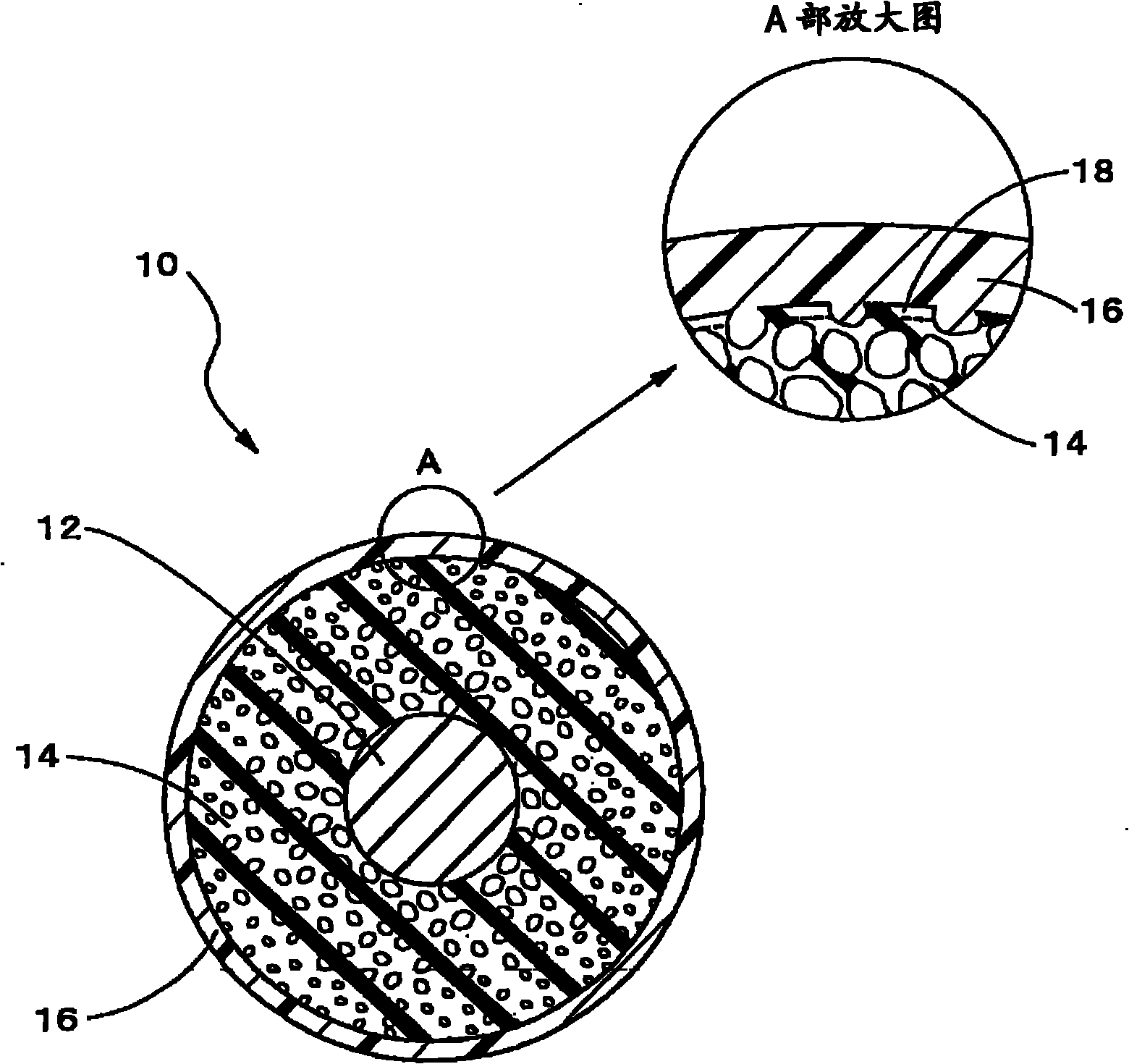

Image

Examples

Embodiment

[0047] Several embodiments of the present invention are given below to illustrate the present invention more specifically, and of course the present invention is not limited by the contents of the foregoing embodiments. In addition, it should be understood that, in addition to the following examples and the content specifically described above, various changes, modifications, and improvements can be made based on the knowledge of those skilled in the art as long as they do not depart from the spirit of the present invention.

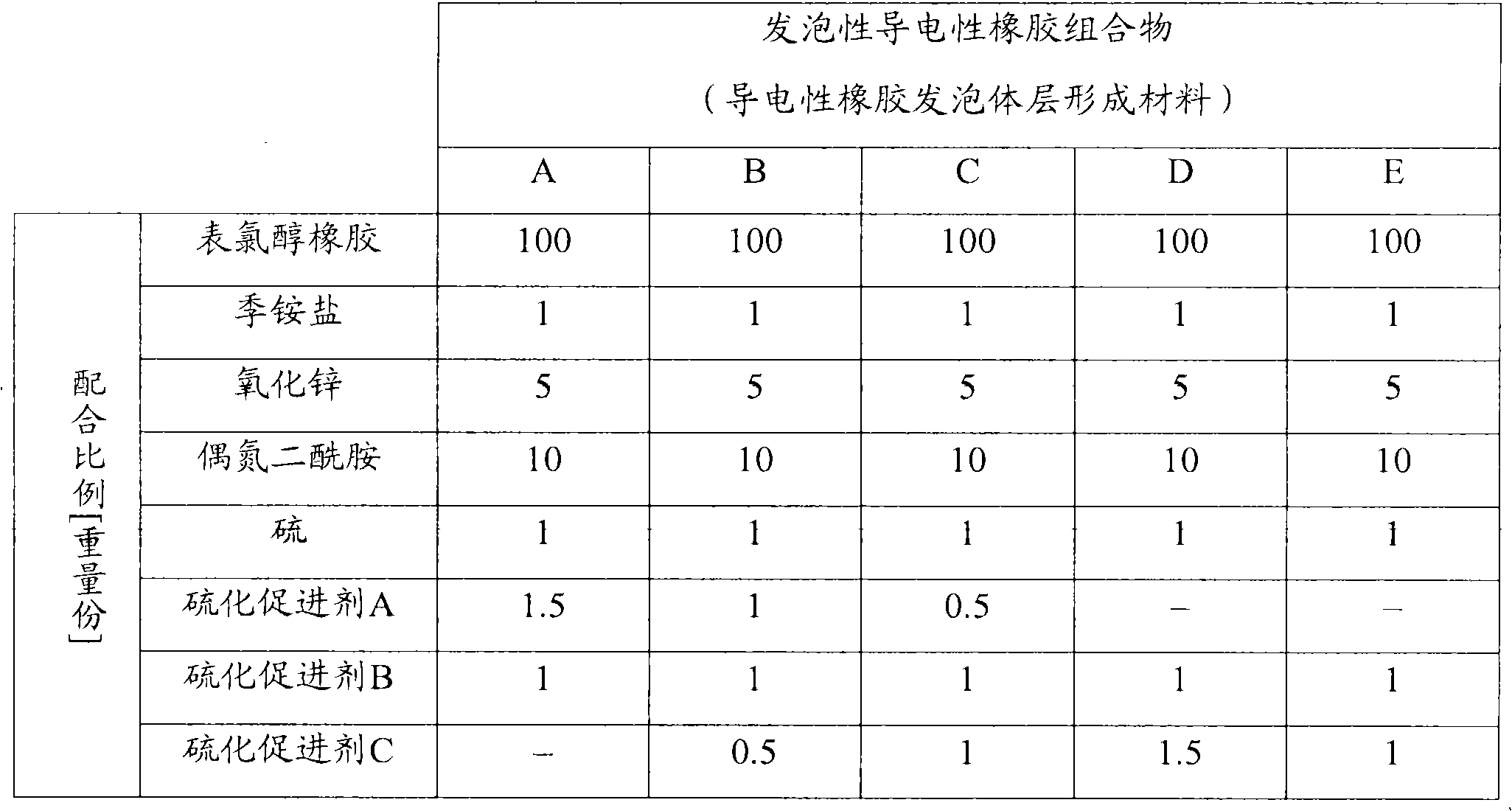

[0048] First, five types of foamable conductive rubber compositions were prepared in accordance with the compounding ratios shown in Table 1 below as conductive rubber foam layer forming materials (A to E). In addition, when preparing each composition, the following rubber materials etc. were used.

[0049] ・Epichlorohydrin rubber: Epichlomer CG102 (trade name), manufactured by Daiso Co., Ltd.

[0050] ·Quaternary ammonium salt: Tetramethylammonium perc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com