Random and automatic regulating polished rod sealing device of oil pumping machine

A technology of automatic adjustment and sealing device, which is applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling, etc., to prevent pollution loss, avoid oil leakage, and reduce the number of packing replacements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

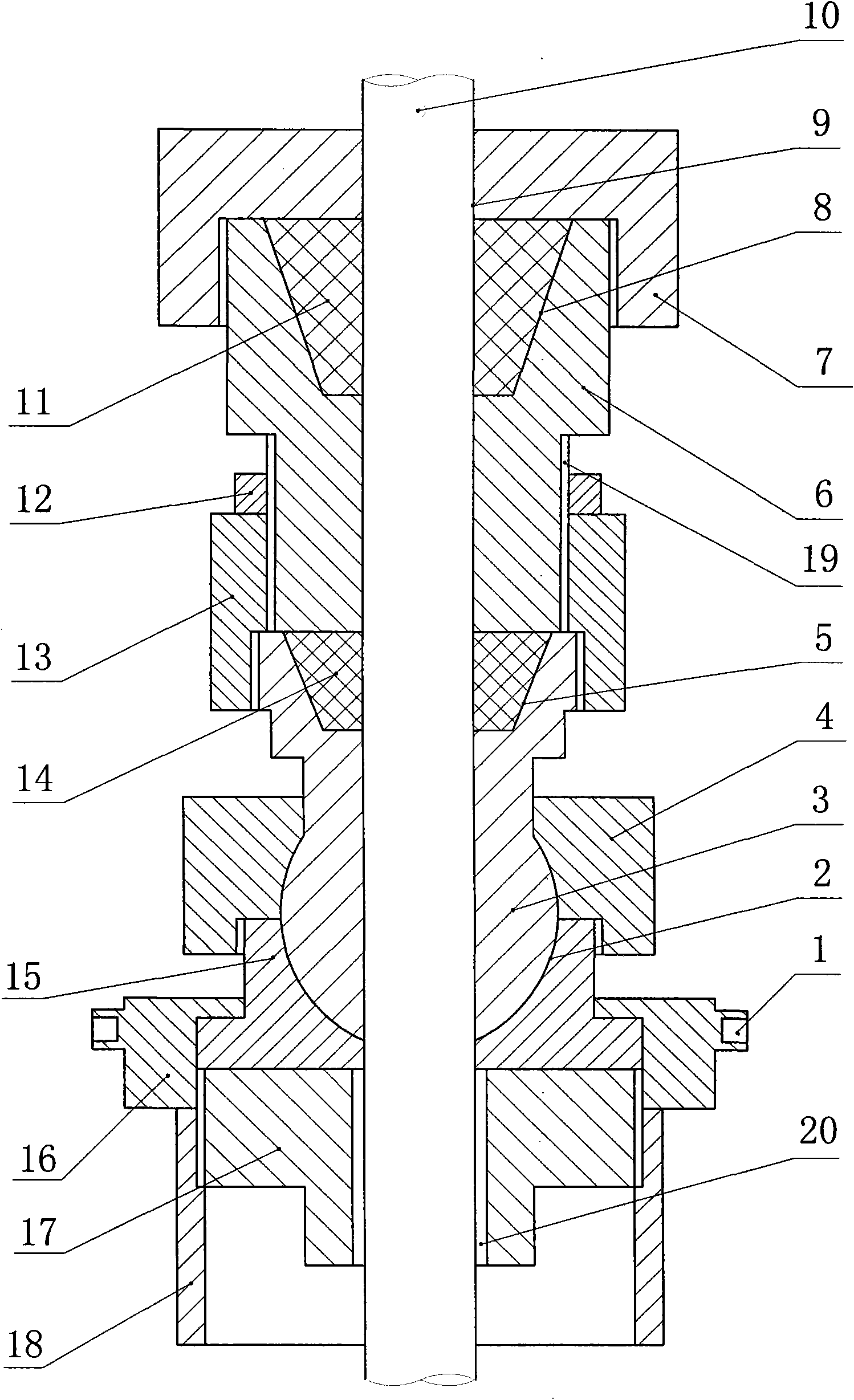

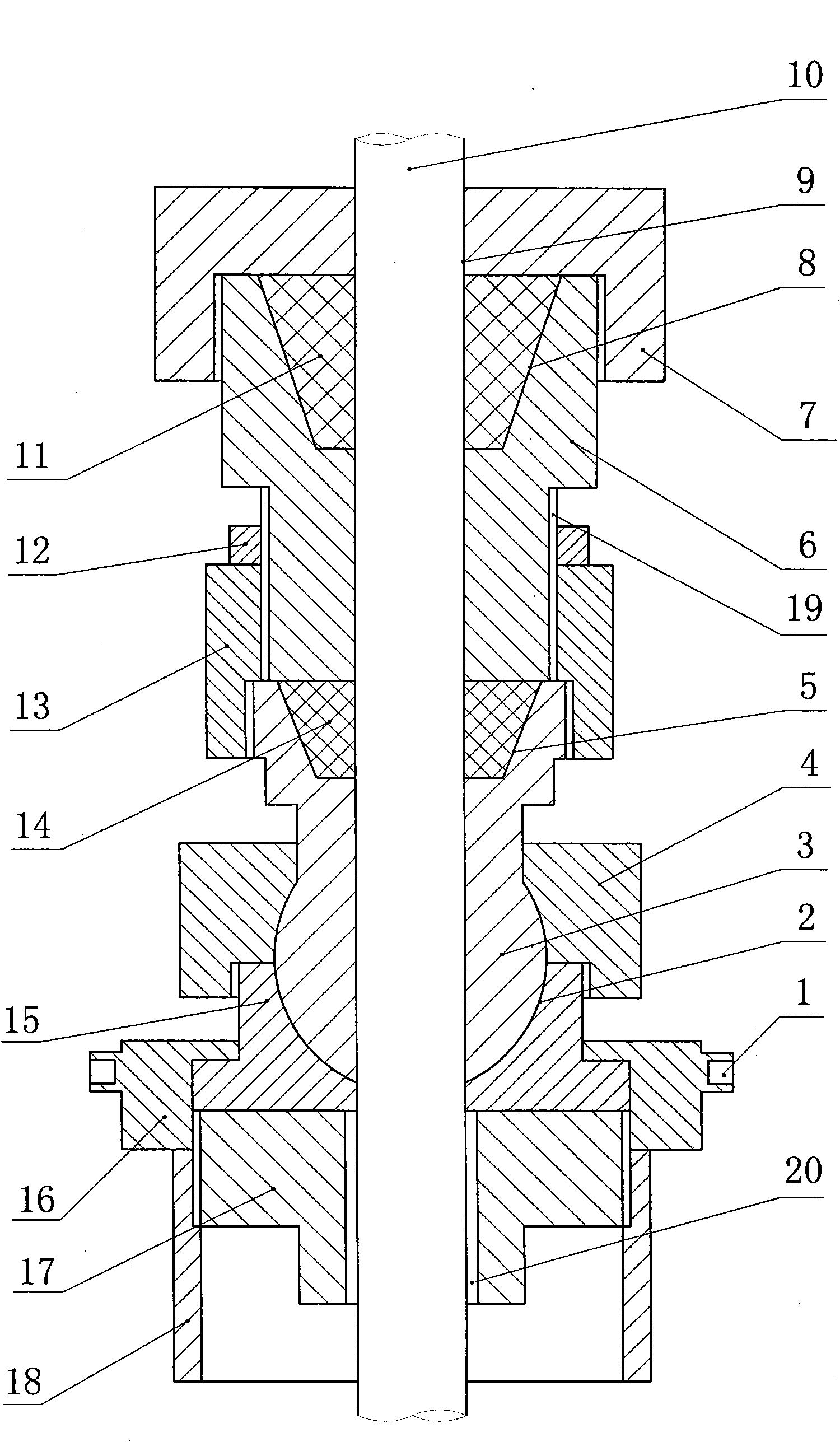

[0018] Such as figure 1 As shown, a random automatic adjustment polished rod sealing device for an oil pumping unit includes a spherical base 17 arranged on an oil well pipe 18, a spherical seat 15 with an arc groove 2 at the upper end is arranged above the spherical base 17, and the spherical seat 15 It is fixed on the spherical base 17 by the translational pressing cap 16 arranged on its outside; the spherical body 3 with the first groove 5 at the upper end is arranged above the spherical seat 15, the arc groove 2 of the spherical seat 15 and the spherical body 3 Corresponding to the lower end of the spherical body 3, the spherical body 3 is fixed on the spherical seat 15 through the spherical pressure cap 4 arranged on the outside; a primary sealing packing 14 is arranged in the first groove 5 at the upper end of the spherical body 3, and the The primary sealing packing 14 corresponds to the first groove 5 on the upper end of the spherical body 3; above the primary sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com