Adjustable sizing block

A technology of pad iron and steel wire retaining ring, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of pad iron boring machine table fixing, low efficiency, unreliable clamping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

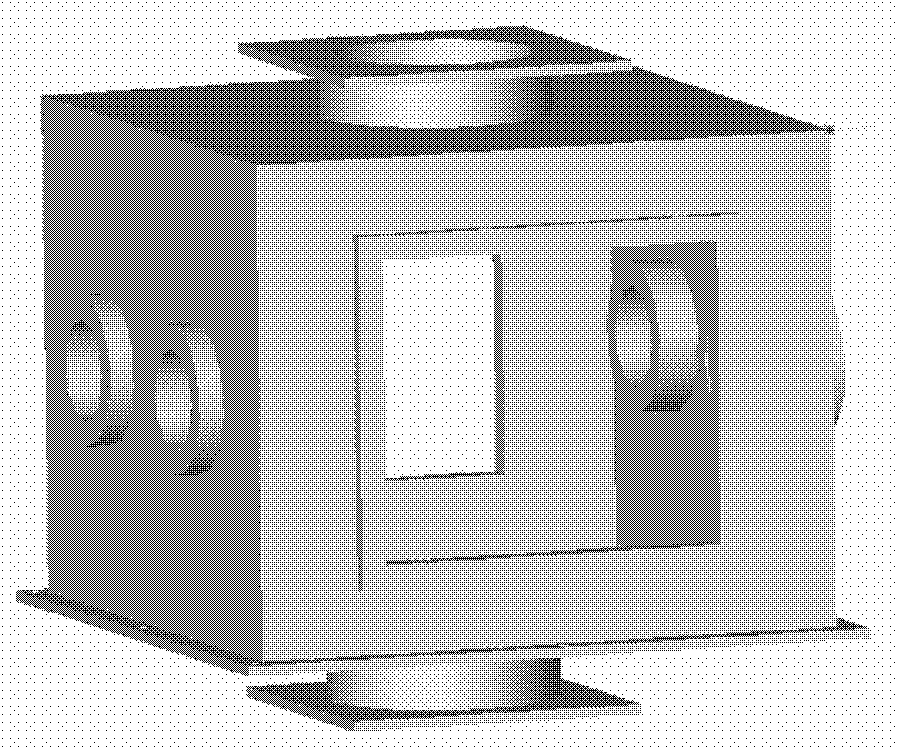

Image

Examples

Embodiment Construction

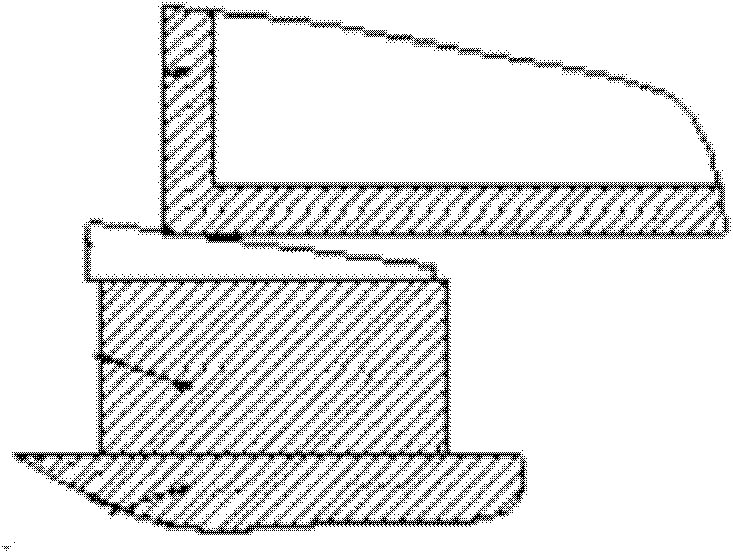

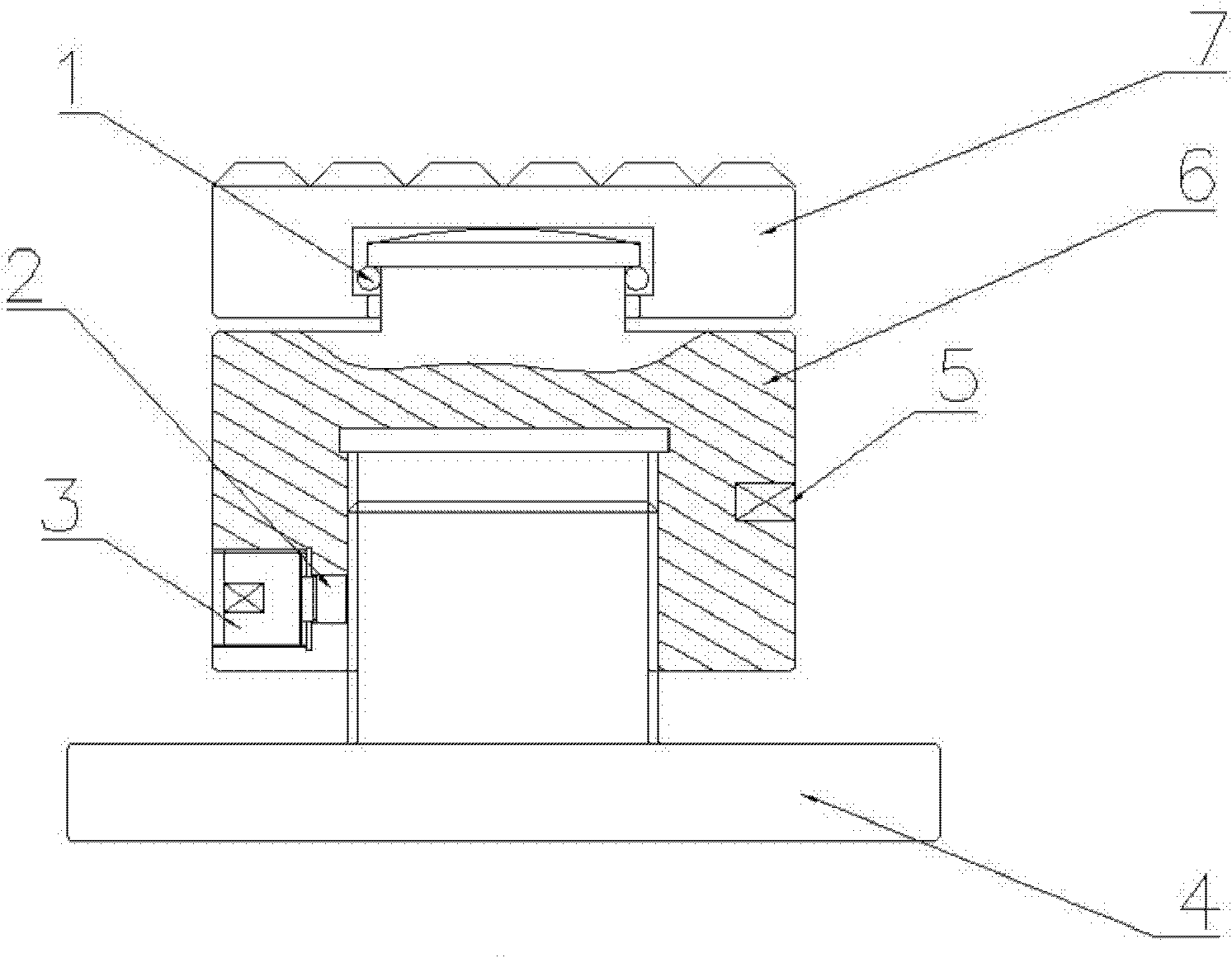

[0013] The details and working conditions of the specific device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Technical scheme of the present invention is: by image 3 It can be seen that the pad iron is composed of a steel wire retaining ring 1, a locking block 2, a locking screw 3, a base 4, a wrench hole 5, a nut sleeve 6, and a top block 7 on the groove surface. The steel wire retaining ring 1 is arranged in the top block 7 of the groove surface, and the nut sleeve 6 is arranged on the base 4 .

[0015] Four wrench holes 5 are evenly distributed along the circumferential direction of the nut sleeve 6 (only one is drawn in the figure), so that the sleeve 6 can be rotated with a supporting wrench 8 to make the groove surface pressing block 7 rise or fall; when the nut sleeve 6 rotates After reaching the ideal position, use the other end of the supporting wrench 8 to turn the locking scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com