Industrial robot and method for controlling the movement of an industrial robot

An industrial robot and motion technology, applied in the direction of program control manipulator, program control, general control system, etc., can solve problems such as process geometry and process speed uncertainty, and achieve the effect of avoiding duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

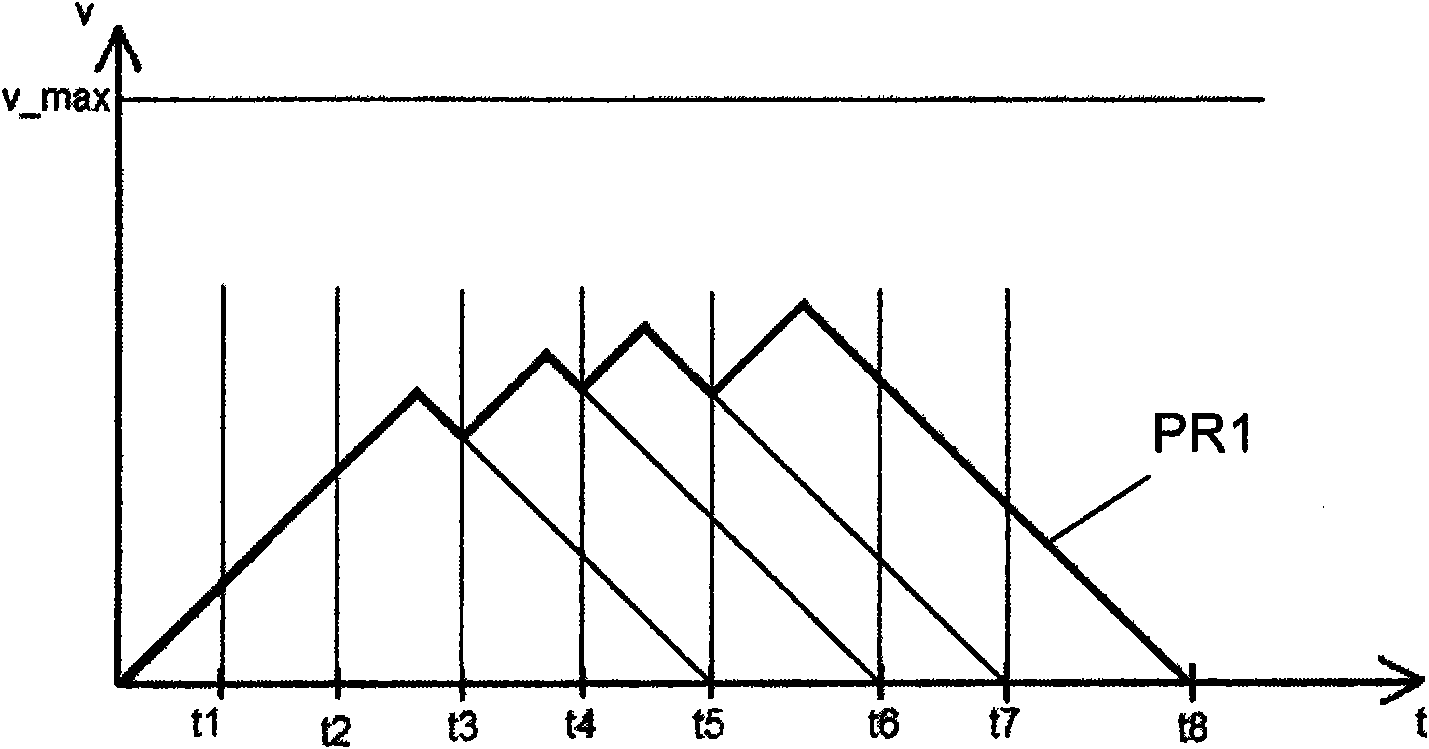

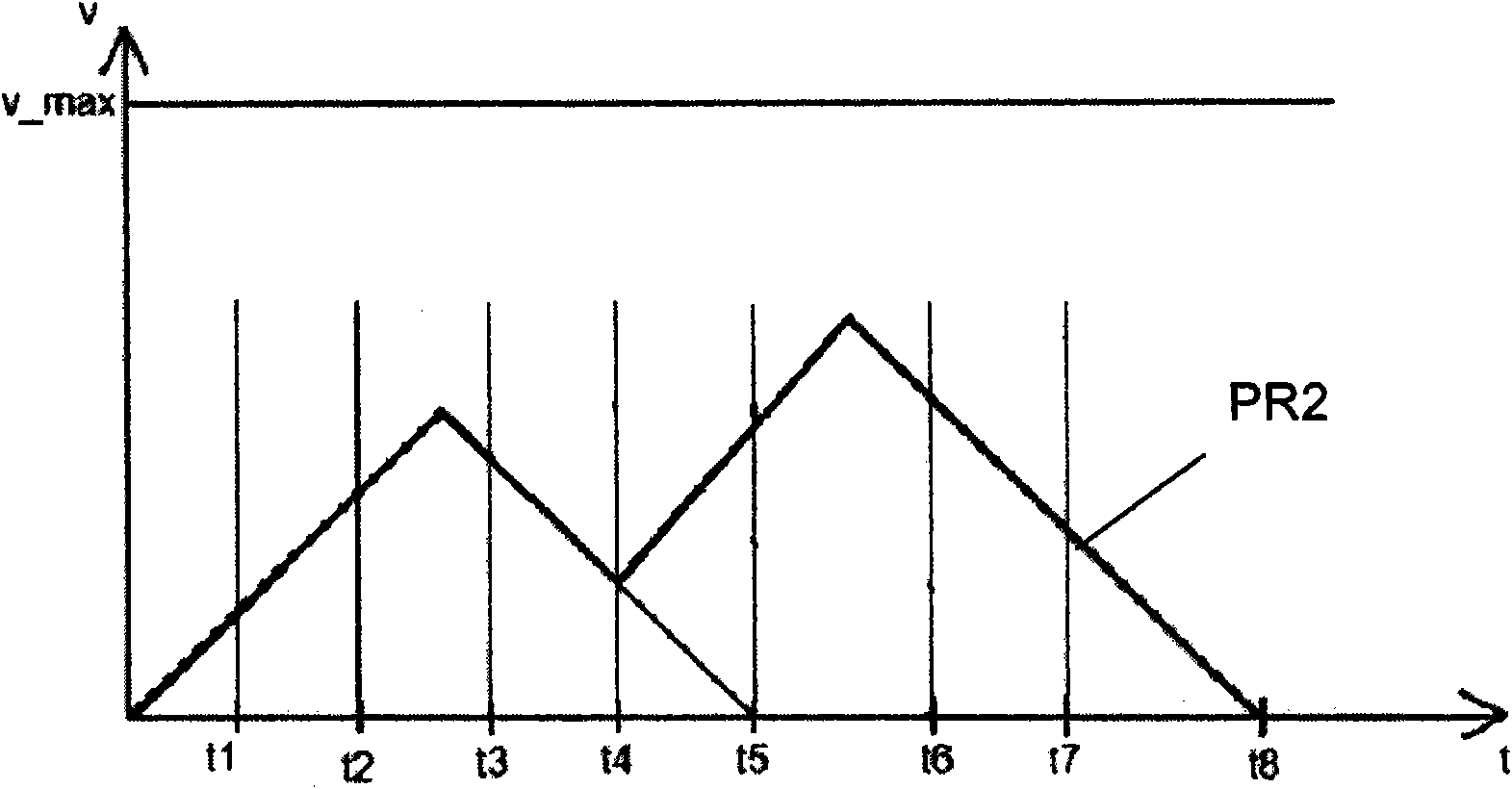

[0077] already in the introduction Figure 1 to Figure 3 Made a description.

[0078] Figure 4 An industrial robot 1 is shown, which has kinematics for movement in, for example, 6 degrees of freedom. The industrial robot 1 has joints 2 to 4 , levers 5 , 6 , six axes of motion A1 to A6 and a flange 7 , on which actuators (not shown), such as tools, can be fastened, in a generally known manner.

[0079] Drives, not shown, move each axis of motion A1 to A6. As known to those skilled in the art, the drive means includes, for example, electric motors and gears.

[0080] In addition, the industrial robot 1 has a control device, which is a control calculator 8 in the present embodiment. The control calculator 8 is connected to the driving device of the industrial robot 1 in a manner not shown, and uses the A program is calculated to control the drive so that the flange 7 of the industrial robot 1 executes a predetermined movement.

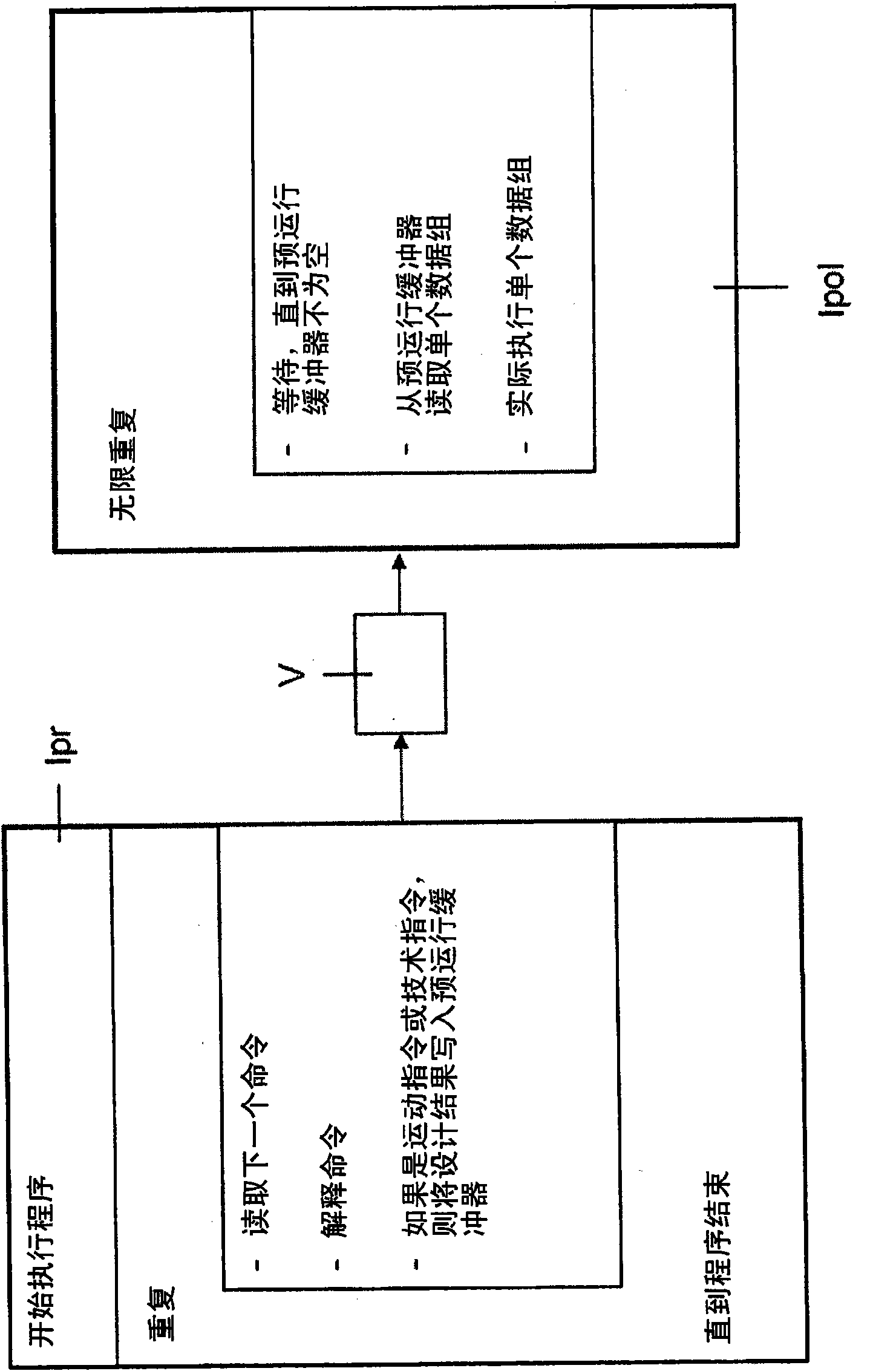

[0081] The control arithmetic unit 8 has a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com